technical / mechanical

engineering

Nurmukhanova A.Z. Candidate of technical sciences, Mukhtarova M.N. Candidate of physical and mathematical sciences, Nurseytova A.K.,

Konakbaev B.O.,

Zulbukharova E.M., Ermaganbetova S. D.

Kazakh National University named after Al-Farabi, City

of Almaty

Republic of Kazakhstan

THE NEW CONSTRUCTION OF THE CENTRIFUGAL MIXER

The

main object of the invention is to improve the device performance by

accelerating the process of mixing the mixture of fractions and lowering energy

costs of the blending process.

The

technical result is achieved in that the centrifugal mixer cyclic operation,

consisting of a cylindrical mixing drum having a rotational axis extending from

the top to the bottom point of the bottoms of opposing intersecting the axis

through the center of gravity of the drum at an angle ![]() lying in the range 30-60°, the minimum value of which equal to or greater than

the angle of repose of the material loading of 30° and longitudinal projections

inside.

lying in the range 30-60°, the minimum value of which equal to or greater than

the angle of repose of the material loading of 30° and longitudinal projections

inside.

For

example, if the ratio is rational ratio of the length of the drum to its

diameter![]()

![]() is

equal to the angle

is

equal to the angle![]() of 39 °, which is greater than the angle of repose of the material for download

in motion.

of 39 °, which is greater than the angle of repose of the material for download

in motion.

When

p=1; 1.25; 1.5 respectively 45°, 39°, 30°, where the lower value of the angle ![]() =

30 ° is chosen equal to the angle of repose of the material in the loading

movement.

=

30 ° is chosen equal to the angle of repose of the material in the loading

movement.

The

invention relates to construction equipment and in particular to the structural

design of the mixer used to prepare mortars, for example of concrete.

The

proposed mixer will be used in construction, in the preparation of construction

mortars and concrete. Operation of the mixer will significantly increase the

productivity of the process while reducing energy consumption.

Set

of claims:

-

The centrifugal mixer consists of a

mixing drum, rotatable about an axis, wherein the axis of rotation of the mixer

is directed at an angle α, which lies in the range of 30-600 to the

geometrical axis and intersects it in the center of the drum and the axis of

rotation passes through the upper line lower point and the opposite end

surfaces of the cylindrical mixer.

-

A centrifugal mixer according to

claim 1, characterized in that the inner surface of the cylindrical mixer

provided with protrusions extending along the drum.

Known mixer centrifugal gravity (À.ñ. 245607 USSR , ÌÊÈ Â28Ñ, pub.

04.06,1969, bul. 19) having a part of the feed screw rotating mixing drum with

down-dropped knives, water supply system. The disadvantage of this mixer is the

complexity of the design, the presence of a larger number of parts.

Known mixer of gravity type, taken as a prototype, (KOROLEV Ê.M. «Mobile

concrete mortar mixers and concrete solutions pumping stations ». Art. 2, - Ì,

High School, 1991 ,p.30) consisting of a mixing drum rotatable around its

geometric axis on the inner surface of the drum are blades. Disadvantage of

this design is the low productivity of the process mixture, high levels of

energy mixing process.

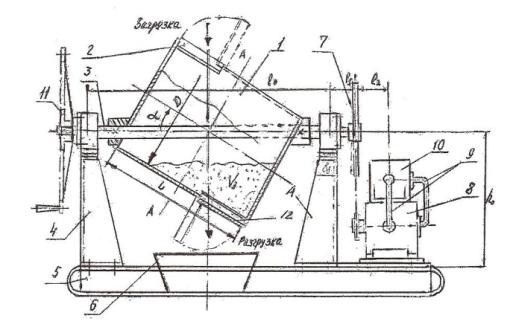

Figure 1 shows a centrifugal mixer. The centrifugal mixer consists of a

cylindrical drum 1 is fixedly mounted on the shaft 3, so that the drum rotation

axis intersect at an angle with the geometrical axis of rotation of the drum.

Figure 1 - Diagram of a centrifugal mixer

Drum 1 has two windows that are used to load and closing hinged lid 12.

The drum 2 and the shaft 1, 3 is mounted in bearing units struts 4 are mounted

on the frame of the mixer 5, in which there is a discharge chute 6. The shaft 3

of the drum, the transfer 7 is connected to the hydraulic motor 8, which

pressure and return line 9 is connected to a regulated hydrodrive

10 mounted on the frame of the mixer.

On the drum shaft 1 has a manual actuator 11 for rotating the drum and

unload the mixture during a power failure.

The mixer operates as follows. When you open the lid 2 of the upper

windows are downloading drum 1 components of the concrete or mortar mixture,

then top window is closed and the hydraulic motor 10 and 8, resulting in the

rotation of the drum 1 through 7 of the chain drive.

During the rotation of the drum is loaded into it the mass of material

mixture is poured simultaneously in two directions along the rotation of the

drum and along its axis, making complex spatial movement that promotes quality

(homogeneity) mixing and reduce the mixing time.

When the rotational speed of the drum 1 is controlled deceleration oil

from the hydraulic circuit 10 depending on the desired composition and quality

of mixing of the components in the incoming-prepare concrete or mortar.

After preparation of concrete or mortar mixer stops in the position

shown in (Figure 1). Windows are opened and the drum 1 is discharged into the

mixed product hopper 6. After discharge, if necessary, washed with water drum

1, the bottom of a hopper window 6 closed by a cover 12, and through the top

window is downloaded component mortar or concrete mix for the next batch. Then

the window is closed with an upper lid 2 and the hydraulic actuator 10 turns

the drum rotation cycle and repeated mixing.

Advantages of the above described construction of the mixer according to

(Figure 1) compared to known types of mixers by cyclic open cavities, with and

without paddles inside them is that:

-

Faucet has a simple structure in

which there are longitudinal projections within the drum and no tilting

mechanism for discharging and its hydraulic adjustment allows different speed

and direction of rotation of the drum;

-

Due to the asymmetry relative to the

axis of rotation of the drum takes place process intensification mixing the

mixture components, by steric bulk material handling load inside the drum in

the circumferential and axial directions simultaneously, which leads to a

reduction of the mixing time and, consequently, better performance mixer

-

The proposed mixer during operation

is closed, the inner cylindrical cavity, which eliminates the release of the

mixture out at high speeds of rotation of the drum.

In addition, for mobile mixers, low-capacity, a manual drive from the

handle 11 is mounted on the end of the shaft 3. In this case, the drive chain

gear 7 is released.

Literature:

1.

Nurmukhanova A.Z., Povetkin V.V., Sosnin V.À. Certificate of authorship ¹ 66405 Centrifugal mixerfrom 15.12.2010,

bul. ¹ 12 s. Astana.

2.

Nurmukhanova A.Z. Evaluation of the

technical condition of the equipment stationary concrete preparatory works.

//Proceedings of the X Anniversary International Scientific Conference

"Science and Education - a leading factor in the strategy" Kazakhstan

- 2030 ". Issue 2 -Karagandy, 2007. - P.454 – 456.

3.

Nurmukhanova A.Z. Analysis of the

causes of failures betonoprigotovitelnyh installations. //Proceedings of the X

Anniversary International Scientific Conference "Science and Education - a

leading factor in the strategy" Kazakhstan - 2030 ". Issue 2 -

Karagandy, 2007. - P.457 – 459.

4.

Erehinsky V.V. Efficiency and

quality of construction. Gorkiy: Volga - Vyatka book. publishing house, 1981.

-223 p.

5.

Kessel L.A. Cost-effectiveness of

new technologies and methods for its determination. – Ì.: GosINTI, 1976 y.