technical / Processing of materials in mechanical engineering

Nurmukhanova A.Z. Candidate of technical sciences, Mukhtarova

M.N. Candidate of physical and

mathematical sciences, Nurseytova A.K.,

Konakbaev B.O.,

Zulbukharova E.M., Ermaganbetova S. D.

Kazakh National University named after Al-Farabi, City

of Almaty

Republic of Kazakhstan

ANALYSIS OF PHYSICAL AND MECHANICAL

PROPERTIES OF MATERIALS NONMETALLIC

This paper analyzes the determination,

dignity, non-metallic materials basis and classification of polymers. Also

provides a method for producing polymers, which are divided into the

polymerization and polycondensation. Describes the process of polymerization of

the chemical compound and a large number of molecules of the monomer in a

larger polymer molecule without changing the elemental composition of the

monomer which leads to the various physical states of the polymer can be

detected by a change in its deformation temperature. The paper presents the

most popular non-metallic materials used as structural, high-molecular chemical

compounds consisting of numerous elementary units, which represent the same

group of atoms and interconnected chemical bonds. We study the different

physical state of the polymer, can be detected by a change in its deformation

temperature dependence of the deformation is considered graphic, developing

over time at a given voltage, temperature. Considered thermal transitions,

which are among the main characteristics of the polymers, the stress-strain for

linear and cross-linked polymers. Substantiates the average

temperature of the transition regions of not crystallization

linear polymer associated with a change in distance between the material

particles, which in turn, at a

temperature below txr resin becomes brittle, which leads to destruction which is a result of chemical bond in the

macromolecule. Crystalline polymers are considered below the melting

temperature - crystallization tk, which are solid, but they have different

stiffness due to the presence of the amorphous part, which can be in different

states.

Keywords: non-metallic materials, structural materials, physical

and mechanical properties, rubber, polymers, plastics, stress, strain, of the

physical state of the polymer temperature recrystallization.

Introduction

The use

of non-metallic materials provides significant economic efficiency. To improve

the physical and mechanical properties, various additives (ingredients). This

material imparts improved physical and mechanical properties (in comparison

with irregular polymers).

Non-metallic materials - are organic,

inorganic and polymeric materials: different types of plastics, composite

materials on the basis of non-metallic and rubber, adhesives, sealants, coatings,

as well as graphite, glass, ceramics. As constructional materials they are an

important addition to metals, in some cases advantageously replaces them and

are themselves sometimes indispensable.

The

advantage of non-metallic materials are such properties as sufficient strength,

rigidity and elasticity at low density, light transmission, chemical

resistance, dielectric properties, make these materials are often

irreplaceable. Also of note is their adaptability and efficiency in use. The

complexity in the manufacture of products from non-metallic materials in 5-6

times lower, they are 4-5 times cheaper than metal. In this connection, use is

continuously increasing non-metallic materials in mechanical automotive,

aviation, food, refrigeration and cryogenics et al. Engines of internal

combustion ceramics dispense with cooling water, which is impossible in the

manufacture of metal; fairings missiles made only from non-metallic materials.

It is hard to household utensils, audio and video equipment, computers, sports

equipment, cars and other equipment without non-metallic materials - plastics,

laminates, ceramics, rubber, glass and others.

The

basis of non-metallic materials are polymers, especially synthetic. Creator of

the structural theory of chemical structure of organic compounds is A.M. Butlerov. Industrial production of the first

plastmass - the result of work carried out by G.S. Petrov, S.V. Lebedev

performed the world's first industrial synthesis of rubber, NN Semenov

developed the theory of chain reactions and distributed on the mechanism of

chain polymerization. The successful development of polymer chemistry and

physics associated with the names of prominent scientists: P.P. Kobeko, V.A.

Kargina, A.P. Alexandrov, S.S. Medvedev, S.N. Ushakov, V.V. Korshak et al.

Development of heat-resistant polymers associated with the name K.A. Andrianov.

In the field of polymeric materials contributed greatly to foreign scientists:

K. Ziegler, D. Nutt et al. [1, 2].

Outlined

in this article describes the most popular material non-metallic materials used

as structural. Macromolecular polymers are called chemical compounds consisting

of numerous elementary units are the same group of atoms linked by chemical

bonds. Macromolecules are long chains of monomers, which determines their

greater flexibility. Individual atoms in the monomers are connected together

quite strong covalent chemical bonds. Between the macromolecules of polymers

are much weaker physical connection. Their molecular weight ranges from 5,000

to 1,000,000 With such large amounts of macromolecules properties of materials

depend not only on the chemical composition of these molecules, but also their

mutual arrangement and structure.

The theoretical calculations

The

equations for calculating the physical and mechanical properties of

non-metallic materials have been used to study changes in materials under the

influence of temperature - is a necessary condition for establishing the nature

of many phenomena and theoretical calculation of stresses and cutting forces.

Polymers

are classified according to various criteria: composition, form macromolecules,

phase state, polarity, with respect to heat, etc. By nature, all of the

polymers can be divided into two groups - natural and synthetic. Polymers found

in nature - organic substances of plant and animal origin, as well as minerals.

The synthetic polymers prepared from single substances by chemical synthesis.

The main advantage of synthetic to natural polymers are unlimited supplies of

raw materials and extensive synthesis of polymers with predetermined

properties. Feedstock for synthetic polymers are the products of chemical

processing of oil, natural gas and coal. The thus-obtained low-molecular weight

substances are called monomers. They are processed into polymers during

subsequent chemical processing.

As a

method for producing polymers is divided by polycondensation and

polymerization. Polymerization - process a large number of chemical compounds

in the monomer molecules per polymer molecule without big changes the elemental

composition of the monomer. In the polymerization process there is no release

of reaction byproducts. The elemental composition of polymers and monomers are

identical. Polycondensation - the formation of a polymer from monomers of

different molecules in a chemical reaction with the release of reaction

byproducts. Elementar composition different from the composition of the polymer

participating in the polycondensation reaction of the monomers. Schematically,

the formula of the polymer are recorded in the form of [M] n where M - the

chemical structure of the monomer; n - index characterizing the degree of

polymerization. On the composition of all polymers are divided into organic,

organometallic, in organic. Organic polymers comprise the most extensive group

of compounds. If the main molecular chain of such compounds formed only carbon

atoms, they are called carbon-chain polymers. In heterochain polymers atoms of

other elements present in the main chain, in addition to carbon significantly

alter the properties of the polymer. Thus, oxygen atoms in macromolecules

contribute to the flexibility of the chain, the phosphorus atoms and chlorine

increase fire resistance, gas barrier sulfur atoms attach fluorine atoms,

according polymer high chemical resistance, etc. Organic polymers are resins

and rubbers. Organometallic compounds not found in nature. This class of

materials is completely created artificially. They comprise a main chain

composed of inorganic atoms (Si, Ti, A1) was combined with the organic radicals

(CH3, C6H5, CH2). These radicals are attached to the material strength and

elasticity, and inorganic atoms reported improved heat resistance. Their

representatives are silicones. By inorganic polymers include silicate glass,

ceramic, mica, asbestos. As part of the carbon skeleton of these compounds are

not present. Basis materials are inorganic oxides of silicon, aluminum,

magnesium, boron, phosphorus, calcium, and others. The organic radicals

consisting of inorganic polymers are absent. By inorganic and include polymers,

basic molecular unit which, as in the case of organic polymers, composed of

carbon atoms, such as graphite and diamond, with graphite and contains a minor

amount of hydrogen atoms. However, unlike organic polymers forming the basic

molecular unit preferably in the form of linear chains, graphite and diamond

form spatial structures. This gives them properties dramatically different from

the properties of organic polymers. Graphite is the only material remaining in

the solid state at a temperature above 4000 ° C and the diamond is the hardest

substance [1, 2].

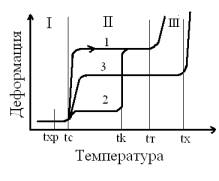

Test data

Various

physical state of the polymer change detected by its deformation temperature.

Graphic dependence of the strain that develops over time at a given voltage,

the temperature is called thermomechanical curve (Figure 1) [3].

Deformation/Temperature

Figure

1 Thermomechanicalnoncrystalline linear curves (1), the crystalline (2) and rarely mesh

(3) Polymer (tc, tk, ty, tx - Tg, crystallization began and the beginning of

the viscous flow of the chemical decomposition, respectively), I-III - portions

glassy, highly elastic and viscous state

On the

curves are three sections corresponding to the three physical states. The

average temperature of the transition regions are called transition

temperatures. Linear nekristalliziruyuschegosya polymer (curve 1), the region I

- Region of elastic deformations associated with the change in the distance

between the particles of matter. At temperatures below thr polymer becomes

brittle. Fracture occurs as a result of rupture of chemical bonds in the

macromolecule. In region II, the small voltage causes movement of the

individual segments of macromolecules and their orientation in the direction of

the force. After removal of the load molecules as a result of intermolecular

forces take the initial equilibrium shape.

Rubbery

state is characterized by significant reversible deformations. Near the point

ty except elastic and rubbery deformation occurs and plastic. Crystalline

polymers below the melting temperature - crystallization tk - are solid, but

have different stiffness (Figure 1, curve 2) due to the presence of the

amorphous part, which can be in different states. When tk-crystalline portion

melted and thermomechanical curve almost abruptly reaches 1 part of the curve

corresponding to the rubbery deformation, as in non-crystalline polymer. Rarely mesh

polymers have thermomechanical type curve 3. mesh nodes prevent relative

movement of the polymer chains. In this connection, when raising the

temperature of the viscous flow does not occur, and extended rubbery region

becomes the upper limit temperature of the chemical decomposition of the

polymer tx. Thermal transitions (tc and CT) are among the main characteristics

of the polymers. The stress-strain for linear and cross-linked polymers are

different. Linear polymers in the glassy state have a certain mobility of the

segments, so the polymers are not so fragile as the inorganic substance. Under

the action of large stresses in glassy polymers developed significant

deformations, which by their nature are close to rubbery. These strains were

named A.P. Alexandrov forced-elastic, and the phenomenon - forced elasticity.

Arte-elastic deformations occur in the temperature range tc - txr, and when

heated above tc they are reversible (Figure 2). The maximum in the curve is

forced to limit flexibility. Polymers with a dense network structure under load

there is elastic and highly elastic deformation, plastic deformation is usually

absent. In comparison with linear polymers of the elastic deformation portion

is a relatively large, highly elastic deformation is much lower. Nature rubbery

deformation as a linear polymer, is a reversible change in the spatial shape of

the polymer molecules, but the maximum tensile strain usually does not exceed

5-15%.

Figure

2. Diagram of stretching: a - a glassy polymer; b - a dense polymer network

structure, I - elastic deformation region; II - rubbery deformation region

For

crystalline polymers, the stress-strain line is expressed with clear

transitions. In the first stage (part I) is proportional to the elongation of

the acting force. Then the sample occurs suddenly "neck", whereupon

the elongation increases at constant power up to a considerable amount. At this

stage, the cervix (section II) is lengthened by a thicker part of the sample.

After the entire sample turned into a neck, the process proceeds to the third

stage (part III), ending rupture. The structure and properties of the material

different from that of the neck and the properties of the original sample: the

elements of the crystal structure are oriented in one direction (recrystallize)

[3].

Literature:

1. J.M.

Lahtin, V.P. Leontiev. Materials science.M.: Engineering, 1990.

2. Edited

by S.I. Bogodukhov, V.A. Bondarenko. Technological

processes of engineering production. Orenburg,OSU,

1996.

3. Source:

http://5fan.ru/wievjob.php?id=6006.