M.S. Bundur, V.A. Prokopenko, P.P. Petkov, N.A. Pelevin

The St.-Petersburg State Polytechnical University

THE

RESERCH OF CONTROL SUSTEMS FOR HYDROSTATIC BEARINGS OF THE MODERN MACHINE-TOOLS

Using of

hydrostatic bearings (HSB) allows almost completely eliminates the wear of pads

of a spindle. Loading ability, a damping, accuracy, vibration resistance

essentially are increased, a friction losses are decreased, thermostability of

machine-tools are essentially increased.

Among the major

variety of control systems for hydrostatical pads (HSP) it is possible to pick

out following basic groups:

·

with the total pump and various control

throttles before everyone HSP;

·

with separated pumps before everyone

HSP.

Different

possible alternatives of the circuit design of control HSP in the HSB of spindle

unit (SU) are observed in discussion:

Alternative 1: in a front (FP) and a back (BP) pads - two throttles at each

co-ordinate axis (it is used in SU of machine-tool LR520PMF-4);

Alternative 2: in FP and BP SU are used two separate pumps;

alternative 2, a - pumps of the equal flow rate; alternative 2, b - the pump flow rate Q2 is twice more than charge

of the pump flow rate Q1; alternative 2, c - the pump flow rate Q2 is twice less than pump flow

rate Q1;

Alternative 3: in FP and BP SU are used one throttle and the pump.

According to

constructive sizes of machine-tool LR520PMF-4 the technological overhang of spindle

is lw=0…1000 mm. That

is why all further calculations was executed for two cases: lw=(1/3)·1000=330 mm.

At a reversion of

external load the operating point of static characteristic of HSP differ for

loading and unloading its branches. Therefore for definition of admitted

bearing ability of SU it is necessary to make separate calculation for loading

and unloading branches of the static characteristic.

For realization

of the greatest productivity of treatment it is necessary to compute the

maximum value of external loading RZmax

at edge HSP displacement δ∑

not more than 50 % of a nominal gap h.

It is determined that for the static characteristic this RZmax = 9500 kN.

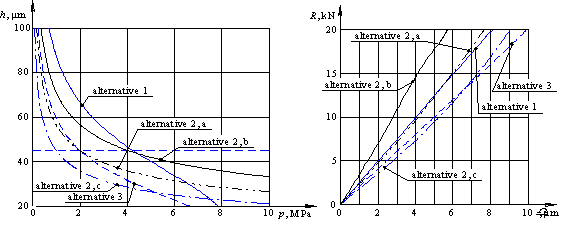

The comparative

estimation of alternatives is made using of static characteristics h=f(p) and loading characteristic R=f(p) which are resulted at fig. 1, a, b

(where p – pressure at HSP).

a) b)

Figure 1: Static characteristics: a – h=f(p)

for various alternatives of circuit designs, b – R=f(p)

for the same alternatives

Under the greatest

loading for alternative 1 the static displacement is 4 µm. The static displacement at same case of loading for alternative

2, à is also 4 µm, but pressure in HSB is decreased more than 2 times. At increase of

productivity of one for pumps 2 times (alternative 2, b) the static

displacement relative to alternative 1 is decreased more than 30 % (is 2,7 µm).

At decrease of productivity 2 times (alternative 2, c) the static

displacement is increased 30 % (is 5,2 µm). For alternative 3 the static displacement

under above mentioned loading is 5 µm. Thus in spite of the fact that alternative 3 provides the least effect

of raise of stiffness and loading capacity, it is the most preferable to

replacement of base alternative, because pressure and consequently the flow

rate of working fluid, significantly are decreased. That is simplifies

maintenance of SU. The throttle permits to realize adjustment of initial

parameters of HSB that is unattainable for all alternatives of modifications of

the pump-pocket.

The comparative

analysis of behaviour hydrostatical pads in dynamics is made on the basis of

the analysis logarithmic amplitude-frequency and phase-frequency

characteristics of model. Key parameter of an estimation of dynamic quality is

the phase stock (Δφ) at

frequency of a shearing (ωc).

It`s estimated that all alternatives have Δφ = 14,8º

– 18,16º and it`s not enough for high quality of dynamic systems. Research of possibilities of increase of dynamic quality at the expense

of conversion to asymmetrical scheme automatic control system (ACS) by radial

displacement of an axis of a spindle without using of correcting RC-chains. The

characteristics of dynamic quality for concentric spindle positions (δ=0) and for various displacements of

an axis of a spindle (δ≠0)

were calculated for all considered alternatives.

For all

alternatives Δφ

are more low of minimum recommended value Δφ=40º. The increase of displacement provides rising of Δφ. The nearest to minimum

admissible phase stock are alternative 2, c (Δφ = 36,2º) and alternative 3 (Δφ

= 34,1º) for displacement δ=15 µm (2,5 times

exceeding a matching parameter of serial machine-tool).

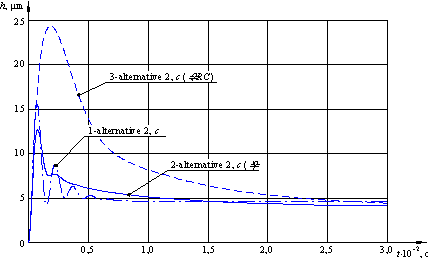

Transient process

for alternative 2, c was obtained (Fig. 2).

Curve 1 for initial alternative has oscillations and consequently dynamic

quality is low. In case of radial displacement of the spindle (curve 2)

oscillation process is particularly eliminated. The best results gives

introduction of mentioned above RC-chains simultaneously with the displacement,

δ (curve 3). This case provides absence of oscillations.

Figure 2: Transient process for

alternative 2, c

In case of necessity

of essential raise of dynamic quality of ACS of HSB may be recommended

introduction of either radial displacement of spindle or RC-chain correction

of HSB or else both these means.