Technical sciences/11. Robotics

Bayasilova Z.A.1, c.ph.-m.s. Baktybayev M.K.1,

d.t.s. Mikhaylov P.G.2

Kazakh

National Research Technical University after K.I. Satpayev, Kazakhstan1

Penza

branch of the Moscow State University of Technology and Management after K.G.

Razumovsky, Russia2

Combined temperature and pressure

sensors

Currently combined temperature and pressure sensors can be used in

various fields of contemporary life: automotive industry, aircraft building,

housing and communal services, oil refining and chemical industry, medicine,

etc.

Measurements of temperature and pressure are required much more often

than measurements of other non-physical quantities. Therefore, temperature and

pressure sensors are extremely in demand. Moreover, all of them possess similar,

well-examined mechanisms. Nowadays hundreds of foreign and domestic companies

actively produce pressure and temperature sensors.

Due to the evident cheapness, semiconductor sensors based on the

strain-resistance effect are of the higher demand rate. Under the influence of

pressure, the resistance of those sensors is inclined to change. The main

disadvantage of these sensors is that the resistance varies not only under the

influence of pressure, but also temperature. This shortage can be eliminated through

installing a thermal compensation scheme. This solution is both simple and

reliable, but still has several disadvantages.

Typically, the thermal compensation scheme is a link located behind the

temperature measurement link. Therefore, the overall output characteristic of

the sensor is considered to be the multiplication product of the two following

link characteristics: temperature compensation and pressure measurement. The

problem is in the fact it is difficult to select a thermal compensation scheme,

so that the temperature affects it in an opposite way throughout the entire range

of both temperature and measured pressures.

The task simplifies in the case we use a combined temperature and

pressure sensor, connected to a microcontroller. In this case, it is enough to

record the pressure-temperature dependence into the memory of the

microcontroller in order to solve the problem. At the same time, you can record

its own dependence for each specific sensor, measured during the way-out from

production. This allows us to increase the lifetime of the sensor, since after

the sensor examination procedure it is possible to record a newly corrected

characteristic of the sensor. However, in the case of the thermo-compensation

circuit, this procedure is so laborious that it is easier to remove this

sensor.

The usage of the thermal compensation scheme in a combined temperature

and pressure sensor gives an opportunity to a further increase in accuracy of

the sensor as well as a decrease in requirements toward the resolution,

accuracy, and length of the measured voltage range in the microcontroller

analog-to-digital converter.

In addition to these advantages, this sensor finds new spheres of usage

where both temperature and pressure measurements are required simultaneously.

Such spheres include rocket engineering, mechanical engineering and heat

meters.

The use of combined temperature and pressure measurement reduces the

cost of the final product, simplifies the process of construction, since

mounting one sensor is simpler than two. For the matter further, it is able to

reduce the distance between the pressure and temperature measurement point up to

zero, which may be necessary for some scientific studies where both temperature

and pressure distribution in space through using a large number of sensors is

especially required.

In order to unify such a sensor, a microcontroller board with an output

interface chip, such as RS-232, RS-485 with MODBUS or PROFIBUS top-level

protocol or short-range I2C, SPI, and Usart interface can be used. This will

entail an increase in the price of the sensor, but heighten the accuracy of the

system and allow to maintain the corrective characteristics in the memory of

the microcontroller. Such a solution will automate the measurement process, the

data will be stored in the memory of the microcontroller every certain period

of time, lead an archive of readings, error reports, create triggers for giving

an alarm when the preset pressure and temperature parameters are exceeded, and

optimize the energy consumption of the sensor. This will ultimately simplify

the task for the developer of the company, acquiring the sensor, which can

compensate for the price increase.

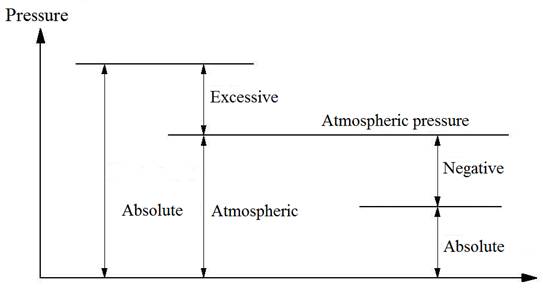

There

are 3 types of pressure sensors, designed for measuring absolute, excessive and

differential types of pressure. Absolute pressure sensors measure pressures

from 0. Differential pressure sensors measure the pressure difference between 2

points. Excessive pressure sensors are considered to be a special case of

differential sensors and measure pressure relatively to atmospheric pressure.

The latter are more widely used in housing and communal services [1].

Picture 1 – Pressure

types

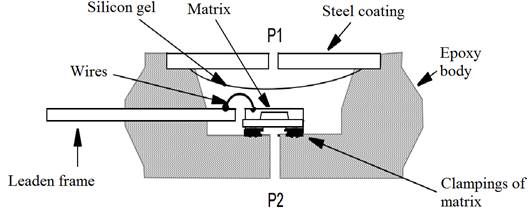

The pressure

sensor is a sensory element placed between two chambers - one from which contains

measured pressure, whereas the other - bearing pressure. In absolute sensors,

the effect on the crystal exists only on one side. One of the world leaders in

the production of semiconductor pressure sensors is NXP Company. In 2016, it

became the fourth in the world in terms of the volume of semiconductor

products. This company produces various pressure sensors in the range from 0 to

10,000 kPa. Let us consider the sensor scheme MPX2100, constructed by NXP in a

section-form, demonstrated on the picture 2 below [2]. This sensor has 7

modifications of different designs, allowing it to be used for measuring all

three types of pressure.

Picture

2 – Absolute pressure sensor [2]

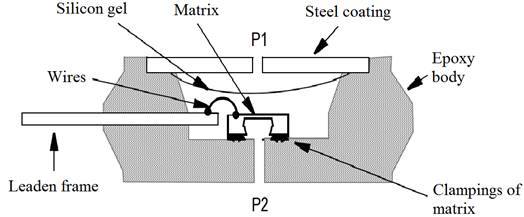

Picture

3 – Excessive or differential pressure sensor [2]

The

absolute pressure sensor is shown on the picture 3, the excessive or

differential - on the picture 2. Apparently, the main difference between the

sensors lies in construction of the matrix. The excessive or differential

pressure sensor suppose that the pressure P1 will always be higher than the

pressure P2, a vacuum is applied in the absolute pressure sensor toward P1. The

silicon gel isolates the silicon matrix and the supply wires from the

environment influence, without interfering with the influence of pressure on the

silicon matrix. The manufacturer indicates that the sensor suppose the exposure

to dry air. Exposure to other gases or mediums may result in inoperability or

shortening the lifetime of the product [2].

The

MPX2100 sensor uses the piezoresistive principle of operation. The point is

that under the influence of pressure differences, the resistance of tensoresistors

changes. The disadvantage of this method is the influence of temperature, for the

elimination of which thermal compensation schemes are applied. In addition, the

temperature can be measured and compensated through a microcontroller [2].

Summarizing,

the addition of a temperature measurement channel and microcontroller to the

sensor allows not only to combine the temperature and pressure measurement in

one sensor, but also to increase the accuracy of the pressure measurement due

to digital thermal compensation.

References

1. Vigleb G. Datchiki. Ustroystvo i primeneniye. – M.: Mir.-1989. –

196 s.

2. Datasheet «100 kPa On-Chip Temperature Compensated and

Calibrated Silicon Pressure Sensors». - Freescale Semiconductor.

- 2008. – 10 s.

3. Mikhaylov P.G., Petrunin

G.V. Sensornyye elementy robotov i robototekhnicheskikh kompleksov. – Penza: PGU. – 1998.

4. Mikhaylov P.G., Belousov Ye.F. Mikroelektronnyye datchiki. Proyektirovaniye, izgotovleniye, diagnostika. -

Penza: PGU. – 2001 – 87 s.