Bezvesilna O., рrof.; Tkachuk A., PhD

National technical university of Ukraine “Kyiv Polytechnic Institute”,

Zhytomyr State

Technological University, Ukraine

THERMO-ANEMOMETRIC FLOWMETER

The

necessity for fuel consumption control is becoming more and more important in

automobile transport design. Flowmeters of various types are aimed to solve

this problem and to avoid fuel misuse. Flowmeters are not only used for

automobile and freight transport, but also for farm machinery (forklifts,

harvesters, and others), for special construction equipment, river and sea

transport, buses, etc.

The

thermo-anemometric flowmeter (TAF) is considered one of the best devices for

measuring the consumption of biofuels [1]. Its main principle is to heat the

fuel flowing to the engine, and to measure the distribution of the temperature

field created by the heater in this flow. The changes of temperature field with

engine fuel flow are determined by the definite functional dependence on fuel

consumption value. That is why it is possible to determine fuel consumption

with high accuracy by measuring the temperature field along the engine fuel

flow axis. This makes the problem of thermo-anemometric flowmeter mathematical

model development of current interest.

The new

flowmeter design uses groups of thermocouples to measure the engine fuel

consumption with higher accuracy. Such a solution provides the determination of

temperature value at the fixed set of points within the engine fuel flow, and

subsequent computer algorithmic equation processing compensates for a number of

measurement errors. Thus, it is necessary to develop a new mathematical model

for this flowmeter. This will allow for measurement of the detailed

distribution of the temperature field at all points of the fuel flow where the

thermocouples are installed. They should be placed in locations where the

medium flow rate is the highest, which will result in an increased heat

transfer coefficient.

The aim

of this paper is to develop the mathematical model of thermo-anemometric

flowmeter [1, 2] and to conduct the corresponding modeling. To achieve this, it

is necessary to analyze the existing mathematical model of the temperature

field in a biofuel flow going through the flowmeter; to conduct

the computer numerical modeling of the heater heat balance in mobile fuel

stream through a TAF; to develop a new mathematical model of the temperature

field distribution along the tube; to calculate the improved value of biofuel

consumption and to propose methods to improve the accuracy and speed of TAFs.

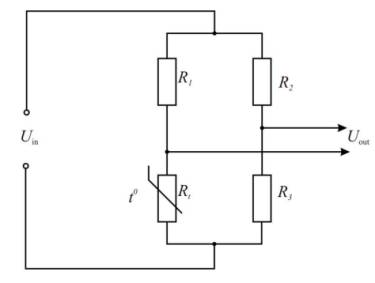

A

thermo-anemometer is a device for measuring fluid flow speed. Its functioning

principle is based on the dependence of convective heat transfer of sensor (S)

on the flow speed, when the sensor is placed in the flow and heated by an

electric current. The measuring bridge is the main part of a thermo-anemometer

(Figure 1). This bridge has the sensor in one of its arms. The amount of heat,

which is transferred by the heated sensor to the fluid flow, depends on the

physical characteristics of the moving medium, piping geometry and sensor

orientation. The higher the temperature of the sensor is, the higher the

sensitivity of the thermo-anemometer is.

Figure 1. Measuring bridge of

a thermo-anemometer (t0—the measured temperature)

Thermo-anemometers

are classified according to the features which characterize the heat mode of

the converter: the way of sensor heating (direct, indirect, continuous, and

impulsive), the type of bridge current (direct, alternating), the type of

electric circuit, etc. There are direct current and constant temperature

thermo-anemometers depending on the converter heat mode.

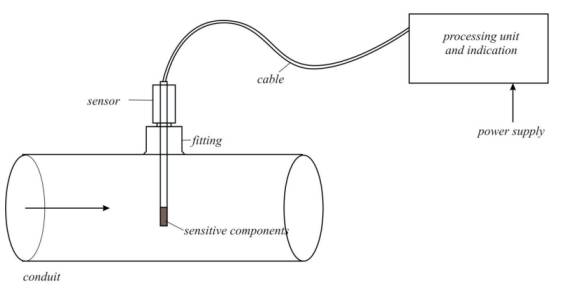

Figure

2 shows the schematic diagram of the thermo-anemometric flowmeter, the sensor,

and the processing and display unit [3-5].

Figure 2. The thermo-anemometric flowmeter schematic diagram

The

bridge of such a generator is powered by a source with high internal

resistance. It provides a constant current value at the sensor changing the

resistance. Due to the fact that the temperature of the sensor changes with

time, the band of recorded frequencies for non-stationary and turbulent flow is

limited because of the sensor thermal lag. This causes a decrease of the

amplitude of the signal at high frequency ω pulsations of times, where

τ is the time constant of the sensor. Thermo-anemometers of the hot wire

type use a very fine wire on the order of several micrometers, electrically

heated up to some temperature above ambient. Fluid flowing past the wire has a

cooling effect on it. As the electrical resistance of most metals is dependent

upon the temperature of the metal, a relationship can

be obtained between the resistance of the wire and the flow speed.

The

designed mathematical model of the temperature field in a biofuel stream coming

through a flowmeter is analyzed in [1, 3, 4]. The computer numerical modeling

for the heater heat balance in a mobile fuel flow coming through a TAF is

performed. It is found that in order to increase the accuracy of the TAF, it is

recommended to measure the temperature of the engine fuel simultaneously at the

corresponding points of flow. The new highly precise flowmeter uses groups of

thermocouples to increase the accuracy of engine fuel consumption

measurements. Computer modeling is performed [1], and it is done at a constant

volumetric flow rate of fuel for the different types of engine fuel, and at

different distances from the heater. The results obtained show that volumetric

flow rate depends on errors of temperature measurements of thermocouples in the

range of relative errors from 0.01% to 1.0%. The results show, that in order to

improve the TAF accuracy it is recommended to apply more complex procedures,

such as approximation of the measurement results by a least squares method and

artificial neural networks.

REFERENCES

1.

Bezvesilna O. Mathematical

model of the thermo-anemometric flowmeter / O. Bezvesilna, I. Korobiichuk, A. Ilchenko, M. Nowicki, R.,Szewczyk // Sensors (Switzerland). 2015, P.22899

-22913

2.

Bezvesil'naya E.N. Investigation of the errors

of a mechanical information-measuring system / E.N.

Bezvesil'naya // Soviet Applied Mechanics.

1990,

№ 4, Р.70-74

3.

Безвесильная Е.Н. Разработка

математической модели термоанемометрического расходомера для измерения расхода

биологического топлива/ Е.Н. Безвесильная, А.Г.

Ткачук, А.В. Ильченко // Журнал “Технологічний аудит та резерви

виробництва” . - 2014. - №5/1 (19) . С. 4-8

4.

Bezvesilna O.M. Flow Measurement and Flow Meters; ZhDTU: Zhytomyr,

Ukraine, 2007.

5.

Bezvesilna O.M.;

Shavursky, Yu.O.; Podchashynsky, Yu.O.; Ilchenko, A.V. Calorimetric flow rate meter of motor fuel with digital processing of

measuring information. Ukraine Patent Number 90985, 6 October 2010.