Технические науки / 4.

Транспорт

Alexey

Shabelnikov

The author of the SECU-3.ORG

project, Ukraine

MICROPROCESSOR

CONTROLLED IGNITION SYSTEM

SECU-3 MICRO

Nowadays,

a lot of old vehicles with contact/distributor based or legacy and/or out of

production distributorless electronic systems are still in use. Spark-ignition

(SI) engines with distributors and especially with contact distributors can't

meet modern economy, power and ecological requirements [1]. Also, if legacy

electronic control unit go down, in majority of cases it can't be replaced,

because it is out of production. One of solutions is to develop ignition

control system using modern components, based on microprocessor. Such systems

are flexible, adaptive and therefore can be easily tuned.

The aim of this work is to

develop microprocessor ignition control system, which will be cheap and open

source − SECU-3 Micro (SECU-3M) [2]. The main input requirements of the

system are following:

▪

open source software [2; 3];

▪

cheap and widespread electronic components;

▪

double sided printed circuit board (PCB);

▪

USB interface;

▪

2 low power ignition outputs (so, wasted spark configuration can be used

on 2 and 4-cylinder engines);

▪

coolant temperature sensor (CLT) support;

▪

crankshaft position variable reluctance (VR) sensor or

Hall-effect/optical sensor support;

▪

wireless communication via Bluetooth;

▪

measuring board voltage;

▪

input for intake manifold pressure (MAP) sensor;

▪

input for throttle position sensor (TPS) or simple throttle limit

switch;

▪

input for switching between two sets of maps (e. g. for

gas/petrol).

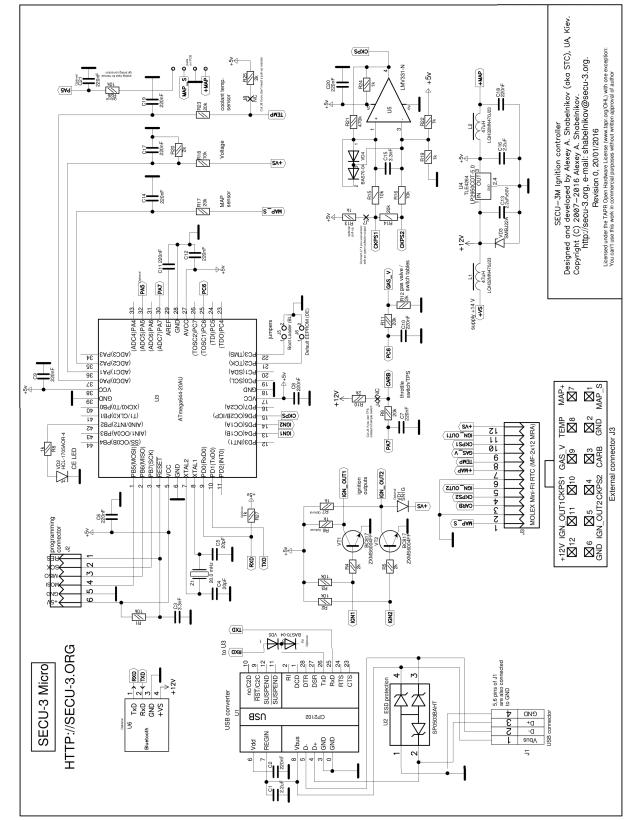

Schematic diagram of the

SECU-3 Micro unit is shown on fig. 1. The core of the system is microcontroller

U3 (ATmega644), which is run on 20 MHz and uses external crystal oscillator.

Connector J2 is for in-system programming (actually it is needed only one time −

for writing out boot loader). There are two jumpers near to microcontroller: J5

and J6. First one is for starting boot loader (intended for use in emergency

cases, e. g. when firmware is broken and boot loader doesn't start

automatically). Second one is for loading backup or factory settings in to electrically

erasable programmable read-only memory (EEPROM).

Light emitting diode (LED) VD2

is for diagnostic purposes (like «Check Engine» lamp). Because system is

relatively simple (no big demand in diagnostics), it is left on PCB. USB

interface is built on integrated circuit (IC) U1. Bluetooth module is shown as

U6. It is separate PCB module, mounted on main PCB by means of 4 pins. We

will not see deep into Bluetooth module in this article.

All discrete and analog inputs

are protected by simple resistor-capacitor circuits (RC circuit). Mentioned

circuits on analog inputs (PA0, PA1, PA2, PA5 pins of U3) also act as simple

anti-aliasing filters [4] for analog-to-digital converter (ADC). ADC uses

reference voltage of 5V. CLT and TPS inputs have optional pull up resistors,

using of which can be configured on PCB. GAS_V input has pull-down resistor

(R12).

IC U5 (comparator) forms input

signal conditioner for crankshaft position (CKP) sensor. This input has optional

pull up resistor (R13), which is needed when sensor with open collector (drain)

output is connected (e. g. Hall-effect or optical sensor). Connecting of

R13 can also be configured on PCB.

Two ignition outputs are built

on transistors VT1 and VT2 with pull-up resistors at inputs and outputs. Diode

VD1 is optional and useful for inductive loads.

Supply for external sensors

(e. g. MAP, TPS or Hall-effect) is decoupled from internal 5V supply using

inductance L2 and capacitor C18.

Fig. 1 − Schematic diagram of the SECU-3 Micro ignition control unit

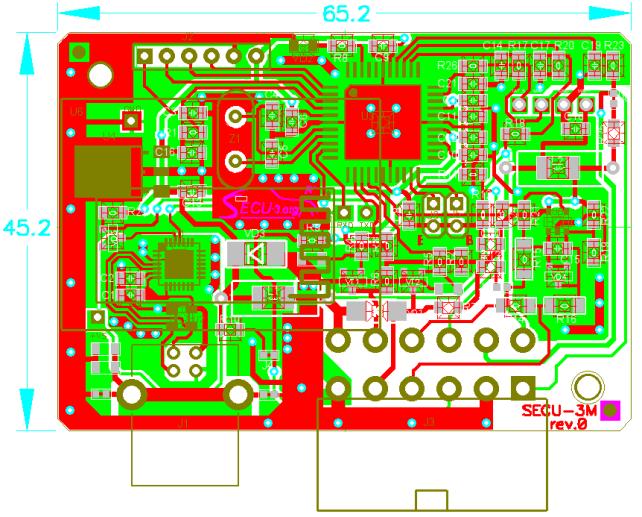

PCB design of the

SECU-3 Micro unit is shown on fig. 2. PCB is double sided and is designed for

mounting into a KM-86 enclosure. Bluetooth module is shown on fig. 3.

PCB design of the

SECU-3 Micro unit is shown on fig. 2. PCB is double sided and is designed for

mounting into a KM-86 enclosure. Bluetooth module is shown on fig. 3.

Fig. 2 − PCB design of the SECU-3 Micro unit

Fig. 2 − PCB design of the SECU-3 Micro unit

Fig. 3 − PCB

of the Bluetooth module

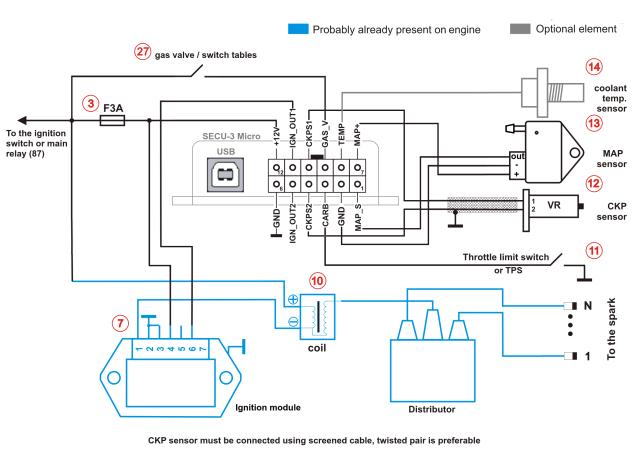

The most typical wiring

diagram of the SECU-3 Micro unit is shown on fig. 4. In this example only

one ignition output is utilized, used single coil with mechanical distributor.

This configuration is very simple and cheap and can be used for

2, 3, 4, 5, 6, 8-cylinder engines. For 1-cylinder

engines distributor is not necessary. On 2- and 4-cylinder engines wasted spark

(distributorless) [5] configuration can be used (in this case additional ignition

module should be connected to IGN_OUT2 output). If IGN_OUT2 output is

not used, then it can be remapped in software for other functions (for

instance: fuel pump control, tachometer output,

shift light etc.).

Fig. 4 − Example of SECU-3 Micro wiring diagram

Fig. 4 − Example of SECU-3 Micro wiring diagram

So, in the article the main ideas and development of the

«SECU-3 Micro» ignition control system are briefly

described. One can see that this system doesn't contain knock sensor

support, integrated ignition coil drivers, plenty of outputs etc, but presence

of mentioned features would lead to a substantial rise in the cost and

complexity of the system. There will be

development of firmware for this unit soon and upcoming testing in laboratory

and on real engines. Author plans to extend

firmware capabilities related to synchronization options and some engine types

(e. g. V-twin) in the future.

References

1.

Транспортная

экология: учеб.-метод. пособ. [для студ. всех

форм обуч. бакалавриата по напр. 280700 «Техносферная

безопасность» (профиль «Безопасность жизнедеятельности в техносфере»)] / сост.

А. Г. Илиев, И. А. Занина. – Шахты: ИСОиП (филиал) ДГТУ, 2014. – 74

с.

2.

МПСЗ

SECU-3 / Ignition and fuel injection ECU [Electronic

resource]:[Site]. − Access mode: http://secu-3.org/.

3.

FreeEMS [Electronic

resource] : [Site]. − Access mode: http://freeems.org/.

1.

Smith, S. W. The Scientist and

Engineer's Guide to Digital Signal Processing /

S. W. Smith; 2-nd Ed. −

San-Diego: California Technical Publishing, 1999.

− 650 р.

2.

Reif, K. Gasoline Engine

Management: Systems and Components (Bosch

Professional Automotive Information) / Konrad Reif. − Wiesbaden: Springer

Vieweg, 2015. − 354 р.