Belyaeva

A.Yu., Cand.Tech.Sc.,

Reasons for the reduction of

cutting force

with ultrasonic cutting.

So, let's start with what ultrasonic cutting is.

Ultrasonic cutting (or dimensional processing) of hard brittle materials

consists in the directed destruction of the processed material under the action

of grains of abrasive material located between the surfaces of the material

being processed and the tool oscillating with ultrasonic frequency in the

longitudinal (axial) direction. Relatively high intensity of the process is

ensured by a high repetition frequency of the instrument impacts (ultrasonic

frequency range) and a large number of grains of abrasive material simultaneously

participating in the cutting (3x10-1x109 per 1m2).

Vibrating with such frequency the tool forces to

penetrate into a processed material of grain of an abrasive material, making

its destruction. If, at the same time, the tool is pressed with a certain force

to the workpiece surface of the workpiece

(or, conversely, the workpiece to the tool), then a

groove is gradually formed on the latter, copying the shape of the working part

of the tool. Thus, ultrasonic cutting is, in essence, a kind of machining of

materials.

Ultrasonic cutting processes all hard brittle

materials having a hardness of up to 10 units on a ten-point Mohs scale. Such materials include glass, quartz, ferrites,

sitall, silicon, germanium, ceramics, porcelain,

various ornamental stones and other materials. Less fragile materials, for

example, a hard alloy, are treated much worse, and plastic and viscous (for

example, steel) by ultrasonic cutting are practically not processed [1].

All of the above are public and known facts from the

school curriculum. And now we shall plunge into the process of turning.

With ultrasonic cutting, it is known that not only

does the cutting force act, but also the sliding friction force. The cutting

force is equal to the product of the area of the cut-off

layer by factors that include a variety of material characteristics and other

characteristics. The frictional force in this case is not of the last

importance in the question of why the cutting force decreases with ultrasonic

cutting.

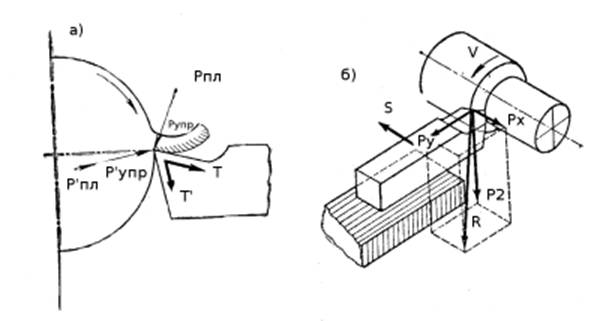

The force acting on the cutter (Fig. 1, a) is usually

applied to the elastic forces Rupr and the plastic Pf

of deformations acting normally to the front surface of the tool, and to the

forces P'upr and P'n,

acting normally to the posterior surface of the incisor [2].

Fig. 1. The forces of cutting and friction during turning.

In turn, frictional forces T = μ (Rupr + Pnl) and T = μ (P'upr + P'n) act respectively

along the front and back surfaces of the tool. The mentioned system of forces

is reduced to the resultant force R (Fig. 1, b).

Friction occurs for two reasons:

1. The roughness of the contacting surfaces when the

frictional force is equal to the product of the friction coefficient by the

normal reaction, and the friction coefficient is the main characteristic of

friction and is determined by the materials from which the bodies are made. N

is the force of normal pressure from one body to another. As a rule, the value

of the friction coefficient of lavas is 0.1-0.5.

2. Mutual attraction of molecules on the surface of

these bodies.

However, according to the law of Amonton-Coulomb,

if the value of the friction coefficient exceeds 1, this means the appearance

of an adhesion force

When the cutter begins to work in the ultrasonic

cutting mode, the workpiece, or rather its upper

layer, heats up sufficiently quickly, to a state called plastic and to which

the friction force is directly related. So, thanks to the frictional force, the

top layer of the piece heats up. Accordingly, to break the top layer of the

part, that is, when the cutter cuts into the top layer of the part and this

layer goes into a plastic state, and the plasticity limit is exceeded, the next

layer is also heated and gradually (in fractions of a second) As the upper

layer. The cutting force is reduced, since there is no need to maintain its

initial value.

Literature.

1. http://www.metalcutting.ru/content/ultrazvukovoe-rezanie

2. http://xn--80awbhbdcfeu.su/silirez