Yurii P. Borodii, Cand. Sc. (Eng.), Assoc.

Prof.

National

Technical University of Ukraine "Igor Sikorsky Kyiv Polytechnic

Institute"

Research and Technology Equipment

With Creation

Hardfacing on Parts of Bodies of Rotation Type

More

efficient use of modern technology in various industries can achieve

continuation of its operational lifetime by surface hardening of working

surfaces, as well as its fast and high-quality repair and restoration parts.

Considerable interest for the practice of electro-spark alloying (ESA), which belongs to the

group of electro methods of surface hardening of machine parts. The main

advantages of the method is the ability to transfer to the surface of the

treated materials of high hardness (carbide) in the high strength of adhesion

layer reinforced with a base coating without significant deformation of the

parts. A significant effect can be achieved using the combined technology of

strengthening of machine parts with a combination of ESA and

surface plastic deformation (SPD).

With the combined strengthening is possible to create multi-layered

wear-resistant coatings on working surfaces of machine parts. At the same time

manages to largely overcome the disadvantages of each method to strengthen and

control the properties of the coating.

We

investigated methods of application-layer coatings:

1. Electro-spark alloying (ESA).

2. Surface plastic deformation (SPD) – break-roller or ball.

In addition, investigated the combined surface

hardening methods:

1. Electrophysical methods and superficial plastic deformation:

- SPD+ESA carbide

electrode+SPD.

- Multiple coating ESA+SPD+ESA+SPD (4 passes) [1].

2. The combination of different types of

electric-spark alloying:

- ESA graphite electrode following ESA carbide electrode, graphite electrode ESA and ESA copper

electrode;

- Coating several layers ESA through different modes.

To assess the effectiveness of the laboratory used

to strengthen research on friction machine on a "shaft-liner" [2]. Studies have

shown an increase in wear resistance of annealed steel U7 (HV 220...240) with a

combined surface after driving 25 km - 4 times, with mileage of 50 kilometers –

2,5 times, and hardened steel 45 (HV 337 and HV 420)

with a combined coverage after driving 22 km by 5 times [2].

On the basis of the studies concluded that

strengthening the combined surface coating scheme SPD→ESA→SPD→ESA→SPD [1] to create a multi-layer structure to increase the hardness of

working surfaces 2-2,5 times and

surface wear resistance in 1,5-5 times. When applying the combined wear-resistant coating scheme SPD→ESA→SPD→ESA→SPD [1] arising from hardened areas of hardened multilayer structure and

several times re-hardened volumes, which increased the composition of

tungsten carbide and lenses.

As a result, developed the technology increasing durability of machines such as shafts, crests

locomotive bogies, axles cement packing machinery, which includes the

pre-deformuvan plastic surface of the ball with a device that is installed in

the tool carriers screw-cutting lathe, mechanized ESA solid smoke using a special alloy head, also

located in the tool carriers. The running mode should be optimal. This primarily refers to efforts of breaking-in (pressure balloons for detail), supply and number of passes. Definition modes of breaking-in complicated by the fact that the relationship between him and the

degree of roughness enhancement and nonlinear. Some optimization efforts by 10

mm balls held in [2]. It was

established that the best steel for plastic load is 200...350 kg. Increased

pressure on the surface leads to a violation of the integrity of the metal on the

surface and the occurrence of peeling surface. The hardness of parts after breaking-in not exceed 50 HRC.

By emerging technologies hardened surface layer,

which on the surface hardness up to 1200 HV. It is accompanied by grinding in

polishing effect.

For the mechanical handling of parts such as bodies

of revolution developed combined technology of wear-resistant coatings. In

general terms, this technology involves the following steps [1]:

♦ preparation details, including machining to final size or the size of

the allowance during grinding;

♦ preparation ESA installation

work, including selection of the optimum currents to electrodes and materials;

♦ preparation for installation of SPD, including the selection of the best

efforts;

♦ coating layer is made: SPD→ESA→SPD→ ESA→SPD;

♦ control measurements to determine the details of the thickness of the

coating;

♦ final grinding to obtain details of the size required for drawing.

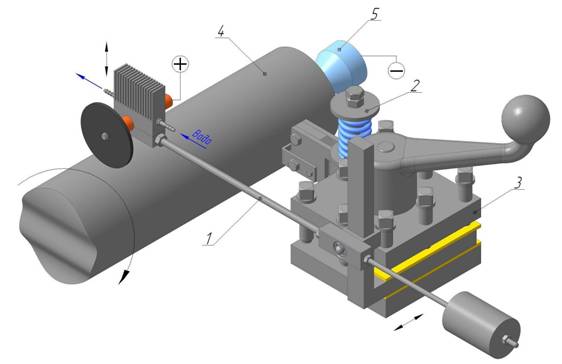

The technology by using specially designed

equipment (Fig. 1). Fig. 1 shows a three-dimensional model diagram of complex devices combined to

form durable coatings on parts such as the shaft.

Fig. 1. Three-dimensional

model diagram of the installation combined to form a wear-resistant coating on

the details of the type of shaft: 1 – a device for ESA; 2 – breaking-in device;

3 – caliper

screw-cutting lathe; 4

– workpiece; 5 – electrically contact

center

Conclusions:

The results of practical interest for various

branches of engineering.

The technological developments providing formation

of coatings with the required performance properties for different parts of machines.

Putting electric-spark coatings and composite coatings increases the

operational stability of the machine parts 3-6 times.

References:

1.

Патент на корисну модель №40858 Україна, МПК В23Н 1/00. Спосіб електроіскрового

зміцнення поверхні металів та сплавів/ Маковей В.О., Бородій Ю.П., Куріхін В.С.

(Україна) НТУУ. – № u2008

13977 Заявл. 04.12.2008; Опубл. 27.04.2009, Бюл. №8.

2. Бородий Ю.П. Экспериментальное

исследование особенностей формирования поверхностного износостойкого слоя

рабочих элементов разделительных штампов/ Бородий Ю.П., Маковей В.А.// Збірник

наукових праць (галузеве машинобудування, будівництво). – Вип. 2 (37). – 2013.

– ПолтНТУ. – С. 61-65.