Gordina N.E.,

Teplyakova N.M., Teplyakova A.N., Prokof’ev V.Yu.

Ivanovo State

University of Chemical and Technology, Russia

Preparation of Granulated

LTA Zeolites from Mechanically Activated Mixtures of Metakaolin

Widely used method for the production of the zeolites is the

synthesis from metakaolin, where the Si:Al = 1:1 ratio corresponds to the

silicate modulus of LTA zeolite. Hydrothermal crystallization in alkaline

solution determines the future course of the process. The solutions of sodium

hydroxide and sodium aluminate are used for the crystallization. The process is

carried out in several stages with different concentrations of NaOH. The phase

composition is determined by both the concentration and temperature during the

crystallization process. The disadvantages of these two methods are high

sensitivity to reagent concentrations and temperature, a substantial duration

of the process as well as the formation of a large amount of waste waters.

We have shown [1, 2] that it is possible to realize the mechanochemical

synthesis (MCS) of zeolites in the activator mills. The advantage of MCS is the

use of dry mixtures that allows one to minimize the amount of liquid phase in

whole synthesis process. The goal of this work

was the investigation of the LTA zeolite synthesis process in the dry mixture

using kaolin raw material in the roller-ring vibratory mill. In order to

increase the content of the LTA zeolite crystalline phase, it is necessary to

optimize the stage of thermal treatment as well as to study deeper the stage of

hydrothermal crystallization.

It was shown that the MCS of LTA zeolite requires the

anhydrous ingredients (metakaolin, alumina, and sodium aluminate). The presence

of structural water in the raw materials (kaolin, aluminum hydroxide, and sodium

gidroalyuminat) gives the formation of undesirable sodalite or nepheline [2].

It was concluded that the synthesis of the LTA zeolite

requires the presence of sodium aluminate of cubic or tetragonal structures

with the lattice parameters close to those of the zeolite. These aluminates act

as a structure directing agent [1]. Sodium

aluminates with other crystal structures and with other lattice parameters

result in the formation of sodalite.

There is an optimal time of MCS, which is determined

by the synthesis of sodium aluminate with a required crystal structure. An

optimum time of the MCS in the vibratory mill was found. This time is

determined by two factors such as the synthesis of sodium aluminate with cubic

or thetragonal syngonis and the absence of sodium aluminate with other crystal

structures (for example, orthorombical syngony). For the vibratory roll-ring

mill used in this work, an optimal time of MCS is in the range of 5–7 min.

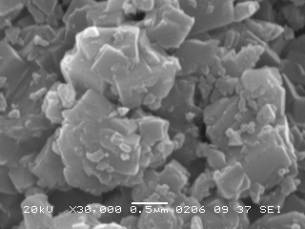

It was shown that the thermal treatment of the mixture

of metakaolin, sodium hydroxide and aluminum oxide which was preliminary

subjected to both mechanical activation in a vibration mill and granulation

results in the formation of the LTA zeolite. The optimum temperature of 600ºC

was determined. The amount of the zeolite was about 65 wt%, while the crystals

have the cubic shapes with the size of 0.2–0.3 μm and were combined into

the agglomerates with the sizes of up to 1 μm (Fig. 1). An increase in

process temperature leads to a decrease in the zeolite amount because the nepheline

is formed. The LTA zeolite crystals consist of multiple microblocks with a

sizes of about 1 μm and have the minimum level of crystal lattice

defects of about 0.15 %. It has been suggested that, during the thermal

treatment, the process of nucleation of a new phase is the limiting stage [3].

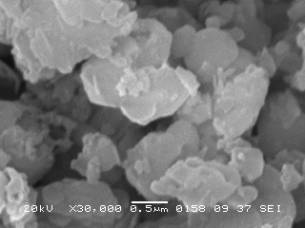

Fig. 1 SEM images of mixture

for zeolite synthesis after 5 min MCS and thermal treatment at 600°C (left) and 700ºC (right)

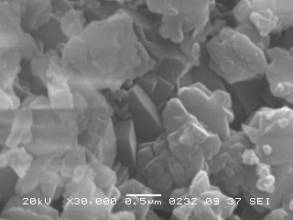

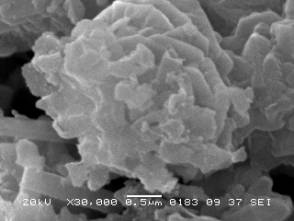

Fig. 2 SEM images

of mixture for zeolite synthesis after 5 min MCA and thermal treatment at 600 °C and hydrothermal crystallization at 2 (left) and 8 (right) mol/l

It was found that the hydrothermal crystallization in

aqueous NaOH solution allows one to obtain the amount of the LTA zeolite more

than 90 wt%. For the 2 mol/l NaOH solution, the crystals have an average size

of 0.6–0.8 μm and are combined into the aggregates with the sizes from 5 to

20 μm (Fig. 2). It was observed that the crystal lattice of the LTA zeolite

has a minimum defectiveness level of about 0.07 %. It is also shown that an

increase in the NaOH concentration up to 4 mol/l results in the formation of

the sodalite, while the size of the LTA zeolite particles becomes to be less

than 0.5 μm (Fig. 2). At 8 mol/l NaOH, only the sodalite phase is formed.

It was proposed that, at low NaOH concentrations, an increase in the amount of

the LTA zeolite is due to the growth of existing crystals. The high level of Na+

cations at higher NaOH concentrations leads to the destruction of the Double-4-Rings

and to linking of the sodalite cages through the Simple-4-Rings.

Reference:

1. Prokof’ev V.Yu. at al. // J. Mater. Sci.

2012. 47 (14). pp. 5385-5392. DOI: 10.1007/s10853-012-6421-3

2. Prokof’ev V.Yu. at

al. // Rus. J. Appl. Chem. 2012. 85 (7). pp. 1077-1082. DOI:

10.1134/S1070427212070142

3. Prokof’ev V.Yu. at al. // J. Mater. Sci. 2013. 48 (18). pp. 6276-6285. DOI: 10.1007/s10853-013-7425-3