Integral assessment of the effects of electric field

on the

speed of the drying process

Nikolaev N.S.

Dr. Ph. Of

Technical Sciences, Professor,

Burlev M.Ya.

Dr. Ph. Of

Technical Sciences, Academic IAR,

Uruypin M.A.

Dr. Ph. Of Technical Sciences,

Moscow State

University of Food Industry,

Russian Federation

Introduction. The results of experimental

research and mathematical modeling of the process of drying of skim milk in a

thin layer with the application of an electric field. Implemented an integrated

assessment of the impact of the electric field at the speed of the drying

process. Graphically shows the dependence of the electric field effect on the

drying process of its key features.

Keywords: skimmed milk, drum (roller)

dryer, mathematical modelling, electrical field, convective drying, drying in a

thin layer, intensification

Many products to dehydration are the

convective drying in a thin layer. To do this, often use drum (rolling) dryer.

The efficiency of the drying process in a drum dryer is associated largely with

the processing time. In addition, it is directly related to, including, and the

size of the drum [1]. In this regard, the intensification of the process of

drying of skim milk in a thin layer is an urgent task that will reduce the size

of equipment, reduce processing time and thus reduce capital investment and

increase energy efficiency. To accomplish this, used the influence of electric

field [2].

Figure of convection drying process in

a thin layer with the electric field presented in Fig. 1.

6

5

4

3

2

1

7 8

Fig. 1. Drum (roller) dryer milk using an electric

field:

1 – screw conveyor; 2 – product (skim milk); 3 –

scraper; 4 – nozzle;

5 – extractor hood; 6 – drums; 7 – electrodes; 8 – pneumatic

transport

Method of Integral assessment:

Remove

moisture under the action of the temperature field.

To

describe the first period of drying mass transfer (constant speed), can use a

known mass linear equation:

-dW/dτ = const = β (Wequil.

– Wavrg.) (1)

W – the moisture content of the material,

kg/kg;

Wequil – equilibrium moisture content of the material,

kg/kg;

Wavrg. – the average amount of body moisture content

material, kg/kg;

τ – time, sec;

β – the mass transfer coefficient, 1/sec.

To

describe a mass transfer of the second period (the period of the falling speed)

using diffusion equation (2-nd Fick's law):

∂W/∂τ

= D (∂2W/∂x2 + ∂2W/∂y2 + ∂2W/∂z2) (2)

D - the

diffusion coefficient, which takes into account a number of internal mass

transfer, m2/sec;

x, y, z – spatial

coordinates, m.

It was for drying

layer of skim milk on the substrate assumed, that is a lot smaller than the

thickness of the substrate, and physical properties of the material are constant

throughout the substrate. In this case, from a three-dimensional spatial

diffusion equation can be one-dimensional equation:

∂W/∂τ

= D (∂2W/∂h2) (3)

h – is the only axis-height in a layer on

a substrate, m.

The initial

condition:

τ = 0, 0

<h <H, W = WB,

H – layer thickness, m;

WB – the initial moisture content of

the material, kg/kg.

Boundary conditions:

τ ≥ 0, h = 0, ∂W/∂h = 0, τ →

∞, h = H, W = Wequil ,

The

exact analytical solution of this equation generally get fails, but using

numerical methods [3], you will get a solution for any given option.

Family

of functions W (h) moisture distribution in the thickness of the thin layer at

regular intervals is shown in the following graph (τ = 0, the initial moisture content W (h) = WB

= const):

Wí,%

Wí,%

|

100 |

|

|

|

|

|

|

|

|

|

|

|

75 |

|

|

|

|

|

|

|

|

|

|

|

50 |

|

|

|

|

|

|

|

|

|

|

|

25 |

|

|

|

|

|

|

|

|

|

|

|

10 Wequil |

|

|

|

|

|

|

|

|

|

|

0 10 20 30 40 50 60 70 80 90 100 h/H/%

Figure. 2. Family of

graphs the distribution of moisture content W in thickness of a thin layer of

skim milk on a substrate at regular intervals.

Remove

moisture under the action of the electric field.

In order to get closer to the understanding of the influence

of electric fields on the process of removing moisture from the product and to

quantify this impact in the form of a supplementary member of the equation

obtained experimental data have been processed, are listed below.

Focused on the experimental data of drying thin layer of

skim milk on the substrate.

Variants:

À0 – without electric impact

À1 - frequency of impulses f1 = 150 Hertz, duty

cycle Q = 3

À2 - frequency of impulses f2 = 200 Hertz, duty

cycle Q = 3

À3 - frequency of impulses f3 = 300 Hertz, duty

cycle Q = 3

À4 - frequency of impulses f4 = 400 Hertz, duty

cycle Q = 3

Â1 - duty cycle Q1 = 2, frequency of impulses f = 200 Hertz

Â2 - duty cycle Q2 = 3, frequency of impulses f = 200 Hertz

Â3 - duty cycle Q3 = 5, frequency of impulses f = 200 Hertz

Â4 - duty cycle Q4 = 10, frequency of

impulses f = 200 Hertz

Voltage

(amplitude) U = 600 Volt

Note: Variants À2 and Â2 are the same and are for

illustration purposes only.

Results and discussion.

Table. 1.

Drying speed-changes per 60 sec. mass fraction in drying thin layer of skim

milk on a W [%/60 sec]

|

60 |

120 |

180 |

240 |

300 |

360 |

420 |

480 |

540 |

600 |

660 |

720 |

780 |

840 |

900 |

960 |

1020 |

1080 |

Variants. |

|

18 |

11 |

9 |

9 |

9 |

9 |

9 |

9 |

9 |

8 |

8 |

7 |

7 |

6 |

5 |

4 |

2 |

1 |

À0 |

|

18 |

11 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

9 |

8 |

7 |

5 |

4 |

4 |

2 |

2 |

0 |

À1 |

|

20 |

25 |

18 |

22 |

21 |

11 |

8 |

10 |

2 |

3 |

0 |

|

|

|

|

|

|

|

À2 |

|

19 |

12 |

9 |

9 |

10 |

9 |

10 |

10 |

10 |

9 |

8 |

8 |

4 |

5 |

4 |

2 |

2 |

0 |

À3 |

|

18 |

12 |

10 |

11 |

10 |

9 |

9 |

9 |

9 |

8 |

10 |

8 |

7 |

5 |

2 |

2 |

1 |

0 |

À4 |

|

20 |

12 |

16 |

12 |

16 |

17 |

15 |

10 |

7 |

6 |

3 |

4 |

1 |

1 |

0 |

|

|

|

Â1 |

|

20 |

25 |

18 |

22 |

21 |

11 |

8 |

10 |

2 |

3 |

0 |

|

|

|

|

|

|

|

Â2 |

|

18 |

17 |

20 |

17 |

19 |

16 |

13 |

3 |

6 |

3 |

2 |

2 |

2 |

1 |

1 |

0 |

|

|

Â3 |

|

18 |

12 |

12 |

11 |

11 |

11 |

11 |

11 |

10 |

9 |

7 |

4 |

5 |

3 |

2 |

3 |

0 |

|

Â4 |

Table. 2. Change the speed of drying thin layer of skim milk on a W

[%/60 sec] due to the electrical effect.

|

. |

60 |

120 |

180 |

240 |

300 |

360 |

420 |

480 |

540 |

600 |

660 |

720 |

780 |

840 |

900 |

960 |

1020 |

The average value of [%/60sec/600V] |

Interval comparison [sec.] |

The value of the argument function |

|

À1-À0 |

0 |

0 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

0 |

0 |

0 |

-2 |

-1 |

-2 |

0 |

1,0 |

180-600 |

f

= 150 Ãö |

|

À2-À0 |

2 |

14 |

9 |

13 |

12 |

2 |

-1 |

1 |

-7 |

-5 |

|

|

|

|

|

|

|

10,0 |

120-360 |

f

= 200 Ãö |

|

À3-À0 |

1 |

1 |

0 |

0 |

1 |

0 |

1 |

1 |

1 |

1 |

0 |

1 |

-3 |

-1 |

-1 |

-2 |

0 |

0,6 |

180-720 |

f

= 300 Ãö |

|

À4-À0 |

0 |

1 |

1 |

2 |

1 |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

0 |

-1 |

-3 |

-2 |

-1 |

0,5 |

180-720 |

f

= 400 Ãö |

|

Â1-À0 |

2 |

1 |

7 |

3 |

7 |

8 |

6 |

1 |

-2 |

-2 |

-5 |

-5 |

-3 |

-6 |

|

|

|

6,2 |

180-420 |

Q

= 2 |

|

Â2-À0 |

2 |

14 |

9 |

13 |

12 |

2 |

-1 |

1 |

-7 |

-5 |

|

|

|

|

|

|

|

10,0 |

120-360 |

Q

= 3 |

|

Â3-À0 |

0 |

6 |

11 |

8 |

10 |

7 |

4 |

-6 |

-3 |

-5 |

-6 |

-5 |

-5 |

-5 |

-4 |

|

|

7,7 |

120-420 |

Q

= 5 |

|

Â4-À0 |

0 |

1 |

3 |

2 |

2 |

2 |

2 |

2 |

1 |

1 |

-1 |

-3 |

-2 |

-3 |

-3 |

-1 |

|

1,8 |

120-600 |

Q

= 10 |

Analysis of

experimental data has shown that in the investigated range during constant

speed the drying effect of the electric field at a rate of close to zero. In

this range, the process of evaporation of moisture from the free product is a

determining and little depends on the influence of the electrical impulse

actions.

For the second

period of drying, the situation is different. From the table. 2 shows that the

difference between the speeds of almost constant drying. Within the limits of

the physical process, described by Fick's equation, which is in the table. 3

designated as "Interval comparison". A simple (not depending from W)

can describe the effect an additional member on the right side of the equation

for the derivative W by time:

∂W/∂τ = D (∂2W/∂h2) – kï(f, Q) U (3)

W – moisture content, %

t – time, sec;

h – height in a layer of dried material, m;

D – coefficient

of molecular diffusion, m2/sec;

U –

voltage (amplitude), Volts;

kn –

coefficient of influence of electric field on drying process of a flat layer,

which is a function of many parameters, including:

f – frequency of impulses Hertz;

Q – duty cycle.

Table. 3. The coefficient kn in units of [1/sec/V] for drying of skim milk on the substrate:

|

Q \ f, Hertz |

150 |

200 |

300 |

400 |

|

2 |

|

1,7 10-6 |

|

|

|

3 |

0,28 10-6 |

2,8 10-6 |

0,16 10-6 |

0,14 10-6 |

|

5 |

|

2,1 10-6 |

|

|

|

10 |

|

0,5 10-6 |

|

|

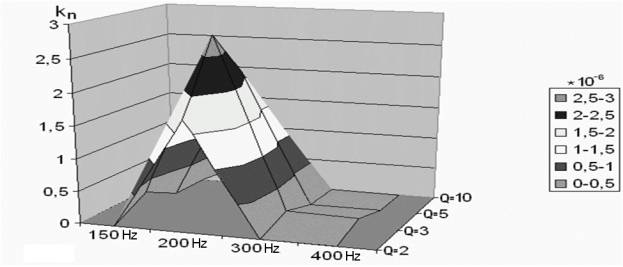

Two-dimensional

surface coefficient kn for drying of milk on the substrate

as a function of frequency f and duty cycle Q is shown in Fig. 3.

Fig. 3. Dependence of the coefficient kn

from frequency f and duty cycle Q.

Modelling of drying process in a thin

layer with the electric field can be the basis for its intensification in a

drum dryer and the results as a basis for the development of more efficient

equipment.

Literature.

1. Ilyukhin V.V., Burlev

M.Ya., Zhukavets E.V. / Drying milk using electric fields // Dairy industry – 2011.

– ¹ 8. - P. 11 - 12.

2. Burlev, M. Ya. Use

of the drying with influence electricity potential in medicine and

pharmaceutics industry // Biomedical and Biosocial Anthropology official

Journal of the International Academy. National Pyrogov Memorial Medical

University. Vinnitsa, Ukraine. December 2011. – ¹ 17. – P. 267 – 269.

3. Guzev O.Yu. "Development

of a high-tech process of fluidized bed dryer with heat pump”. Diss. of Ph. Tech. of Sciences.

M. – 2008.

148

pages.