Tadeusz

MARCINKOWSKI; Wojciech SŁOMKA

Wroclaw University off Technology

Institute of Environment Protection Engineering

ANALYSIS OF EFFECTS OF INDUSTRIAL WASTE LANDFILL

ON SUBSURFACE WATER

INTRODUCTION

Vehicles scrap, metal scrap, as well

as used home and industrial electric and electronic equipment, are waste that

contain hazardous components, such as heavy metals, oil products, etc.[1].

In case of inappropriate or

erroneous dealing with such waste, they may endanger human life and health or

the environment. Recovery and recycling of raw materials from waste is on the

one hand a challenge for our civilization, and on the other hand a legal

requirement [2,3,4].

During recovery of raw materials

from these groups of waste a significant mass of byproducts is created (waste

from waste processing), the quantity of which in case of the neutralization

plant analyzed here may reach as much as 30% of initial mass subjected to

processing. This quantity includes a considerable portion that is not suitable

for management and can only be disposed on a landfill.

Neutralization plant is located in

south-west region of Poland and has the own industrial waste

landfill that is being monitored since its launching in the year 2001. Monitoring

refers to the quality of piezometric water in the vicinity of the plant.

The obligation of monitoring of

landfills results, among other things, from the legislation of the European

Union that with the aim of environmental protection as a whole, and

protection of human health in particular requires avoiding high

concentrations of hazardous pollutants in subsurface water, reducing them or

preventing their formation [5].

Our research was directed to aspects

of safe depositing industrial waste as well as the quality of subsurface water

in the vicinity of the landfill.

ACTIVITY OF

THE SCRAP MATERIAL PROCESSING PLANT

The scrap processing plant presented

here is one of the biggest in the country. Apart from purchasing metal scrap,

the plant deals with conversion of used household equipment and auto hulks and

other large-size waste, and for two years also of used electric and electronic

equipment.

Productive activity of the plant is

based on the processing line presented schematically on Figure 1. The main

element of the line are high-duty rippers crushing scrap and a technological

process, in which crushed waste is subjected to sorting and segregation into

particular morphological fractions. Some fractions are marked out to

reutilization (ferrous and non-ferrous metals and separated so-called

alternative fuel). The remainder, in shape of the finest fraction, sorted on a

sieve of 15 mm mesh, as well as other unmarketable

waste, are transferred to deposition on own landfill located in the southern

area of the plant (Figure 2).

Figure 1. Processing line for scrap disintegrating.

Description:

1 ripper-crusher,

7 non-ferrous metals separator,

4 rotary sieve, 10 container

for flammable waste,

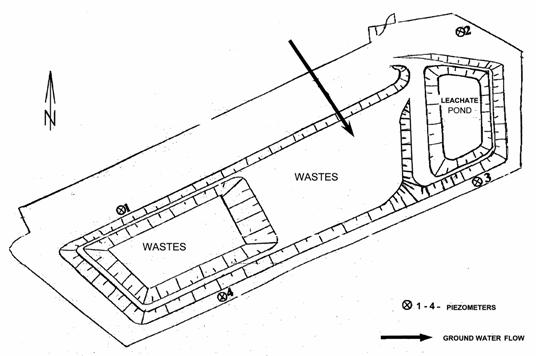

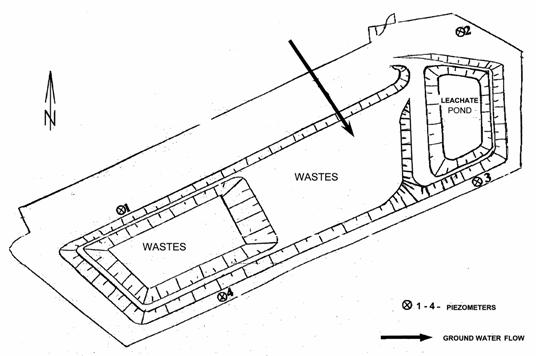

Figure 2. The landfill of industrial waste.

In order to determine the

environmental effect of deposited waste, a preliminary analyses of the

physicochemical composition of raw waste as well as of water extract of this

waste were performed [6]. Results of this research are summarized in Tables 1

and 2.

Table 1. Physicochemical

composition of the fine fraction of waste [6].

|

No.

|

Parameter

|

Unit

|

Trial 1

|

Trial 2

|

|

1

|

pH

|

|

7,5

|

7,5

|

|

2

|

Moisture content

|

%

|

13,93

|

9,03

|

|

3

|

Organic mass

|

%

|

11,43

|

16,47

|

|

4

|

Ammonia nitrogen

|

mg NNH4/kg d.m.

|

90,74

|

74,92

|

|

5

|

Organic nitrogen

|

mg Norg/kg d.m.

|

61,13

|

2140,64

|

|

6

|

Overall nitrogen

|

mg Nog/kg d.m.

|

151,87

|

2215,56

|

|

7

|

Acid-insoluble

substances (SiO2)

|

% d.m.

|

28,17

|

24,64

|

|

8

|

Calcium

|

mg Ca/kg d.m.

|

21085,92

|

20644,91

|

|

9

|

Chromium

|

mg Cr/kg d.m.

|

484,625

|

436,099

|

|

10

|

Zinc

|

mg Zn/kg d.m.

|

27499,56

|

27546,20

|

|

11

|

Cadmium

|

mg Cd/kg d.m.

|

121,244

|

132,127

|

|

12

|

Nickel

|

mg Ni/kg d.m.

|

510,455

|

170,075

|

|

13

|

Iron

|

mg Fe/kg d.m.

|

273502,0

|

303775,1

|

The analysis of physicochemical

composition of fine fraction of waste from tests 1 and 2 showed high content of zinc, iron and calcium.

Elution tests of these metals, both

for trial 1 and trial 2 (Table 2), demonstrated low solubility in water, that is a result of their metallic

form..

Water extracts of waste deposited on

the landfill were made four times later, in different periods (Table 2). They

showed slightly increased pH, quite low value of specific electrolytic

conductivity, as well as low content of nitrogen compounds. Despite of high

content of metallic forms of metals (that occur in that form in solid samples

due to their origin), they do not produce a significant environmental hazard. Table

2 also shows a beneficial effect of alkalization (with hydrated lime in a dose

of 2.5%) on intensivity of elution of metal compounds from waste.

The

examination of environmental effects of deposited waste was performed on the ground

of cyclic observation of changes in subsurface water quality in the vicinity of

the landfill.

In

order to do that, four piezometric drawholes were made to the depth of the

first water table (about 5-6 m under the ground surface level).

The direction of groundwater flow was determined as being from north-east

towards south-west. On account of dense industrial building on the northern

side, piezometers were localized in the immediate vicinity of the landfill

(Figure 2).

Piezometers

P1 i P2 were designed to observation of the quality of water flowing into the

landfill. Comparing the quality of water in piezometers P3 and P4 to the

quality in piezometers P1 and P2, effects of deposited waste on water

environment were analyzed. In addition, changes in composition of eluates were

observed. Samples of eluate were taken from the pond located in western part of

the landfill (Figure 2). Eluates flow down to the pond through the system of

drain pipes [8].

For

analysis of changes in subsurface water an overall observation of the landfill

parameters, as well as of the manner of waste and eluates management were

helpful.

Piezometric

water was collected with small pumping set equipped with two submerged

rotodynamic pumps having efficiency of 5 dm3/min and elevation

head of 10 m. Before taking samples, purifying

pumping of piezometric drawholes was performed, drawing out about triple volume

of stagnating water from each drawhole.

The

ground of decision about sampling was a stability of specific electrolytic

conductivity and pH, measured during clarification of drawholes.

The

following parameters were determined in samples of water: pH, specific

electrolytic conductivity, nitrogen compounds, CODCr and metals (Zn,

Cr, Ni, Hg).

Determination

of parameters was performed according to the reference methodologies [7].

Figure 3. Changes in subsurface water quality during

control observations general indices.

Figure

5. Changes in subsurface water quality

during control observations metals.

Expected and logical progress of

plots of analyzed contaminants concentrations is presented for specific

electrolytical conductivity and COD. The correlation between these parameters

can be easily found (Figure 3). Values of COD and conductivity in water flowing

to the landfill (piezometers P1 and P2) are

lower than in water flowing out from the landfill (piezometers P3 and P4).

However, this is not a situation observed during the whole period of research,

nor for all contaminants analyzed.

In some cases water from piezometer

P2 had the highest or very high values, e.g. for CODCr. Observation

of the landfill during sampling was helpful in interpretation of such a state. It

was found that after heavy precipitations leaks occur through the embankment of

the landfill from the pond of drain on its western side (Figure 2). A portion

of this water penetrates into the drain pond, but it does not affect

concentrations of contaminants in the pond. It was also observed that a

significant portion of leaks found its way out along the access road to the

landfill quarter, according to the slope of terrain, to the vicinity of

piezometer P2. Soaking in the ground, these leaks cause contamination of water

in this piezometer. Therefore piezometer P2 should be excluded from

interpretation of measurement results untill the western enbankment would be

sealed and subsurface water in the vicinity of this piezometer would purify spontaneously.

Instances of high or the highest

values of contaminants concentration (e.g. mercury) were also found in

piezometer P1. It proves that some more contaminated water flows into the

landfill, causing increased contaminants content in piezometers P3 and P4.

Influence of waste on subsurface

water should be interpreted on the ground of correlation between concentrations

of contaminants in eluates from the pond and in water from piezometers located

in the vicinity of the outlet from the landfill (P3 and P4). Such a situation

in water quality can be observed in case of CODCr and specific

electrolytic conductivity. It is

additionally confirmed by similar tendency in changes of contamination of water

from these piezometers and in drains from the pond.

In general evaluation of changes in

contamination during the period of observation only small effect of the landfill

on water environment was observed.

Observation of tendencies in changes

of contaminants concentration during the last year of research demonstrated the

increase of subsurface water contamination with nickel and organic compounds

(CODCr), as well as the increase of salinity, measured as the

specific electrolytic conductivity.

Concentrations of examined

contaminants in subsurface waters (Figures 3 and 4) are lower or comparable to

these in water extracts from raw waste (Table 2), what confirms rather slight

influence of waste on subsurface water quality in the area of the landfill.

SUMMARY

Preliminary examination of raw

waste, observation of changes in contaminant concentration in subsurface water,

as well as observation of practices employed in landfill exploitation and

waste/eluates management, taken altogether into consideration, create ground

for proper interpretation of influence of waste on the water environment.

CONCLUSIONS

1. Waste that comes into existence

should be utilized to the highest possible degree, therefore minimizing the

surface area and volume of the landfill, as well as minimizing its

environmental impact (total load of contaminants and diversity of their

indices).

2. Post-production remainders should be

deposited in the quarter of landfill and not be used directly in construction

of embankments and ground levelling. Such materials do not thicken properly and

are evidently leaky. They can also be a direct cause of subsurface water

contamination.

3. Enbankments of the landfill should

be sealed and the drainage of eluents made passable. This will enable to avoid

influence of leaks on subsurface waters.

4. Careful choice of location of

monitoring piezometers will enable to create actual view of contamination

background and explicit interpretation of changes and influence of waste on the

environment.

References: