Àinagul Òîleuova, Dauletkhan Smagulov

K.I. Satpaev Êazakh National Technical

University, 050013, Êàzakhstan,

Almaty

Studying aluminum angle of Al–Cu–Mn–Zr system phase diagram as a base

for obtaining refractory aluminum alloys

Introduction

Recently there have rather actively been studied metastable condensed

systems possessing a number of new physical-and-mechanical properties differing

from the properties of equilibrium systems. A special place among them there is

taken by nanostructured materials whose volume significant part make grains

boundaries. Traditionally non-equilibrium (amorphous, nano- and microcrystal)

states in aluminum alloys are obtained by methods of the melt fast quenching,

mechanical alloy-forming and others.

With new technologies development there are made demands for structural materials quality, particularly, to aluminum alloys with transition metals possessing high operational and special physical properties, such as refractoriness, plasticity, fracture toughness and some others. To achieve these aims there are improved methods of materials treating in both liquid and solid states. To the first group there are referred temperature-temporal treatment and the melt high-speed crystallizing; to the second one – intense plastic deformation and thermal treatment.

Fast-quenched aluminum alloys containing 0.05 wt% by weight transition

metals (Zr, Fe, Cr) showed their good advantage as a base for prospective

refractory granular alloys mainly due to forming in them oversaturated solid

solutions. However, obtaining oversaturated solutions by the method of

high-speed crystallizing is connected with great technical difficulties. In

this connection there arises the necessity to look for other methods of

obtaining necessary structural state and the outside effects, for example,

intense plastic deformation that would assist the forming of certain structural

states ensuring the necessary level of the abovementioned alloys operational

characteristics.

In the present work with the aim of determining the zone of

concentrations and temperatures at which there can be achieved the maximum

level of refractoriness, there has been

carried out the quantitative analysis of Al–Cu–Mn and Al–Cu–Mn–Zr systems phase

diagrams. With the help of Thermo-Calc program there have been calculated the

corresponding isothermal and polythermal sections of phase diagrams, as well as

determined the temperatures of liquidus

and solidus.

Experimental studies

The analysis of the

alloys chemical composition (Table 1) shows that type 1201 alloys have significantly higher copper concentration

but lower manganese and zirconium concentrations than in ALTEK alloy. This

difference in concentration of alloying elements defined the key difference of

these alloys structure and properties.

Table 1. Some deformable alloys composition

based on Al–Cu-Mn-Zr system

|

Grade |

Cu, at% |

Mn,

at% |

Zr,

at% |

Others |

|

D201 |

6.0–7.0 |

0.4–0.8 |

0.2 |

Ti |

|

12012 |

5.8–6.8 |

0.2–0.4 |

0.1–0.25 |

Ti,

V |

|

ÀÀ 22193 |

5.8–6.8 |

0.2–0.4 |

0.1–0.25 |

Ti, V |

|

ALTEK4 |

1.2–2.4 |

1.2–2.2 |

0.15–0.6 |

Sc, V |

1BSt, 2SSt 4784-97, 3specification of The Aluminum Association (USA) 4 RF pat.

No 2252975 (publ. 27.05.2005, Bull. No 15)

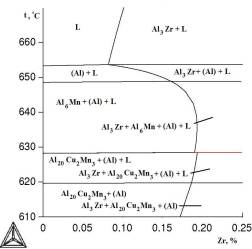

Adding zirconium to binary alloys is known to

lead to forming Al3Zr phase [1]. Zirconium is known to increase greatly the liquidus temperature in

binary alloys. The calculation shows that copper presence effects but little

the degree of this increase that is demonstrated by polythermal sections shown

in Figure 1, as well as the data presented in Table 2.

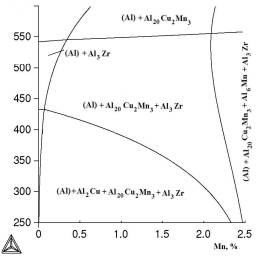

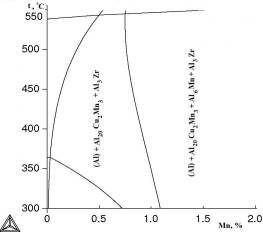

From Table 2 we can see that a mere addition of copper doesn’t

almost effect the alloy crystallizing character. In non-equilibrium conditions

of crystallizing manganese solubility in aluminum increases, and a ternary

compound formation is suppressed. That’s why in such alloys alongside with (Al)

there co-exist phases Al2Cu and

Al6Mn. After forming virgin crystals

(Al) there occurs separating phases Al2Cu and Al20Cu2Mn3 in the following reaction: L→(Al) + Al2Cu + Al20Cu2Mn3 at the temperature 547 °Ñ. With the further increasing of copper concentration there are not

observed significant changes.

Table 2. Parameters of Al–Cu–Mn–Zr system characteristic alloys crystallizing

|

Cu, at% |

tL,

°C |

tS,

°C |

Phases |

|

2 |

730 |

628 |

(Al) + Al20Cu2Mn3 + Al3Zr + Al6Mn |

|

5 |

731 |

576 |

(Al) + Al20Cu2Mn3+ Al3Zr |

Though in literature there are no data on building a diagram of 4-component Al–Cu–Mn–Zr system, phase zones distribution in the aluminum angle of this system in solid state can be predicted based on the existing information.

à

b

Fig.1.

Polythermal sections of Al–Cu–Mn–Zr system with varying zirconium

content: à) 2 at% Cu and 1.5 at% Mn; b) 6.5 at% Cu and 0.5 at% Mn

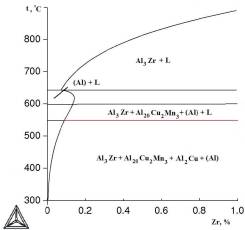

One of the most important

characteristics of any alloy is the liquidus (TL) and the solidus (TS)

temperature. With the help of these temperatures there are determined the modes

of thermal treatment, temperatures of alloys melting and casting. The results

of calculating TL and TS for some alloys of Al –Cu–Mn– Zr system are

shown in Table 2. Starting from the calculation results we can conclude that

copper doesn’t effect TL significantly but decreases TS obviously. On the other hand, adding 0.4 at% Zr already

increases the liquidus over 800 °C. The temperature effect on the phase zones location is shown on

the calculated polythermal sections with varying manganese content (Figure 2). It’s

obvious that with copper concentration decreasing from 2 to 1 at% there

decreases the probability of phase Al2Cu

forming. The

temperature effect is reflected by polythermal sections with varying manganese

content shown in Figure 2. Here we can see that copper content decrease from 2

to 1 at% decreases the probability of forming Al2Cu phase.

à b

Fig.2.

Polythermal sections of Al–Cu–Mn–Zr system with varying manganese

content: à) 2 at% Cu; b) 1 at% Cu: calculation for metastable phase Al3Zr (L12)

Conclusions

In the work based on Thermo-Calc program there

has been carried out the analysis of Al–Cu–Mn and

Al–Cu–Mn-Zr phase diagrams as a base for cast and deformable refractory aluminum

alloys.

To develop

refractory alloys designed for operating up to 350 0Ñ there

are suggested the alloys of Al–Cu–Mn–Zr system. As compared to industrial

alloys of 1201 type it is suggested to decrease copper content and to increase

manganese content. This will permit to obtain in the final structure the

maximum number of the secondary aluminides Al20Cu2Mn3

that (alongside with dispersoids Ll2) assist the hardening, especially at

increased temperatures. Besides, new alloys don’t require homogenization (as

the maximum plasticity is achieved in a cast state), that permits to decrease

significantly the deformed half-finished products cost.

References

[1] Ìînfoldo L.F. Structure and properties of aluminum

alloys. - Ì.: Ìåtallurgy, 1979.

[2] Belov N.A. Phase composition of aluminum

alloys: Scientific edition. – Ì.: MISiS publ. house, 2009. – 392 p.

[3] Belov

N.A., Alabin A.N. Prospective aluminum alloys with addition of zirconium and

scandium // Non-ferrous metals, 2007, No2, p. 99-106.

[4] RF patent No 2001145, Ñ22Ñ021/00. Cast alloy

based on aluminum / Belov N.A. Nov.15, 1993.

[5] Belov N.A. Structure and hardening of cast

alloys of Al – Ni – Zr system. Metal science and thermal treatment of metals.

1993, No 10, p.19–22.

[6] Belov N.A., Naumova Ye.A. Structure and

properties of cast alloys based on aluminum cerium system prospective

materials, 1999, No 6, p. 47–56.