Ôèçèêà/2.Ôèçèêà òâåðäîãî òåëà.

Svetlana A.

Barannikova1,2, Galina V. Shlyakhova1,3, Lev

B. Zuev1,2

1Institute of

Strength Physics & Materials Science, SB RAS, Tomsk, Russia

2National

Research Tomsk State University, Tomsk, Russia

3Seversk

Technological Institute affiliated to NIYaU MIFI, Seversk, Russia

Investigation

of the Localized Plastic Deformation Zone of Superconducting Cable

Using atomic

force and optical microscopy methods, the changes in the

microstructure within the localized plastic deformation zone were investigated for the alloy Nb47%Ti used

for the manufacture of superconducting cable employed as current-carrying

elements in the International Thermonuclear Experimental Reactor [1,2].

Several layers of material 0.5-mm each were removed with the aid of abrasive

from the latter zone to be examined by metallography technique. It was found

that all the Nb-Ti strands of the inner layer adjacent to the copper core have

a round shape. The treatment by cold drawing has left traces in the intermediate

layer of the region adjacent to the copper core. The Nb-Ti strands in the outer

layer are rhomb-shaped. The cross-section topography was examined by the

methods of optical and atomic-force microscopy. After the region adjacent to

the copper core had been polished with abrasive to a depth of 0.5 mm, Nb-Ti

strands on its border would assume irregular shape and would form a localized

deformation zone similar to that observed for as-received Nb-Ti strands which

have not been polished (Fig. 1 a, b). In the point of rupture the

intermediate copper matrix layer separating Nb-Ti strands had average grain

size ~850 nm. The statistic treatment data suggests that the average grain size

of the defect-free zone of the copper matrix has average grain size ~800 nm,

which is comparable to that of copper in the point of rupture, i.e. ~850 nm [1].

The profilogram obtained for the cross-section polished to a depth of 0.5 mm

shows a Nb barrier in the point of rupture, which surrounds Nb-Ti strands

within the copper matrix. This presents a series of high-amplitude sharp maxima

having width ~250 nm, which is similar to that observed for as-received

material without polishing. A similar Nb barrier surrounding Nb-Ti strands in

the location of breakage was observed for material that had been polished to a

depth of 1 mm.

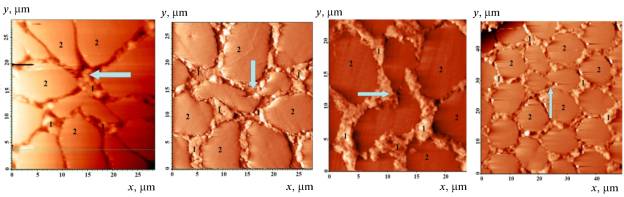

(a)

(b) (c) (d)

(a)

(b) (c) (d)

Fig. 1 The AFM image of the zone of

localized plastic deformation at the point of breakage of Nb-Ti strands

(designated by arrows): 1–copper matrix; 2–Nb-Ti strands; depth of polishing: (a) 0 mm; (b) 0.5 mm; (c) 1 mm; (d) 2 mm

Metallography investigation was performed

for Nb-Ti strands cross-sections, which were subjected to etching and polishing

to a depth of 1 mm. It was found that Nb-Ti strands appear to be unchanged by

comparison with as-received unpolished material. However, the localization zone

has a different aspect (Fig. 1 c).

The lobe-like strands coalesce to form one strand, which suggests that the

strands are of different thickness. The Nb-Ti strands within the localization

zone assume a round shape. The structure of section surface, which had been

polished to a depth of 2mm, was examined in an optical microscope. The general

aspect of localization zone is found to have changed significantly relative to

as-received defect-free state. The Nb-Ti strands in the point of rupture

gradually form a conglomerate (Fig. 1 d);

the near-lying Nb-Ti strands have a round shape, which is characteristic for defect-free

zones. It should be noted that another defect was found to occur in the

vicinity of boundary between the intermediate layer of Nb-Ti strands within the

copper matrix and the copper core, i.e. two Nb-Ti strands of irregular shape,

which had smaller size relative to the near-lying ones. Using the contact

method of AFM technique, we examined the cross-section surface of Nb-Ti strands

which had been subjected to etching an polishing to a depth of 2 mm. In this

case, a Nb barrier is found to occur on both the inner and the outer surface of

the Nb-Ti strands in copper matrix. As noted above, a similar Nb barrier had

been observed previously in a defect-free area of as-received material; this

shows in profilograms as a series of high-amplitude narrow maxima having width

≤ 250 nm. The evolution of localized plasticity zone is illustrated in

Figs. 1. Thus, the area next to the cable copper core is found to contain

localized deformation zone in the point of rupture of Nb-Ti strands. Moreover,

the Nb barrier is present only partially in the same area, which is indicative

of a varying extent of deformation in the sections, which were polished to

depths varying from 0.5, 1 and 2 mm. A major drawback to the conventional

approach employed in the analysis of the ultimate

tensile strength of superconductors on the base of Nb-Ti alloy is the

conceptual representation of plastic deformation as a steady-state and

homogeneous process. The experimental evidence for the nature of plastic

deformation strongly suggests that at the early stages of straining the plastic

deformation would exhibit an inhomogeneous behavior, which is liable to cause

formation of localized plasticity nuclei [3]; in one of these nuclei rupture of

cable strands would occur. The macro-scale localization of deformation has been

studied in sufficient detail [3].

The work was performed in the

frame of the Tomsk State University Academic D.I. Mendeleev Fund Program and

the Program of Fundamental Research of State Academies of Sciences for the

period 2013-2020 yrs.

References

1. L.B. Zuev, G.V. Shlyakhova, S.A.Barannikova, S.V. Kolosov,

Microstructure of elements of a superconducting alloy Nb-Ti cable, Russ. Metal.

2013 (2013) 229-234.

2. G.V. Shlyakhova, S.A. Barannikova, L.B. Zuev,

On structure of localization zones of plastic

deformation in superconductive cable based on Nb-Ti alloy, Metallofiz. Nov. Tekhnol. 35 (2013) 453 – 465.

3. L.B. Zuev, V.I. Danilov, S.A. Barannikova, V.V. Gorbatenko, Autowave

model of localized plastic flow of solids, Phys. Wav. Phen. 17 (2009) 1–10.