O. Yaremchuk, Å. Gurinovich

Petro Mogyla Black Sea

national university, Ukraine

automated control system

of illumination

in the laboratory of

physics

Formulation of the problem and its connection with important scientific and practical tasks. As you know, high level of light in the room creates a feeling of

discomfort and rapid eye fatigue. It also can damage the light-sensitive plants

in the absence of the owner. Especially when the sunlight gets into the room.

Low illumination also can lead to negative results [1-3].

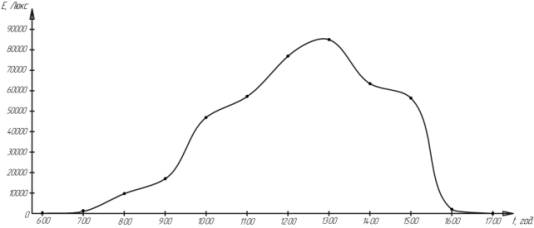

Previous studies of light level in the room (E(t))

show that lighting is much more than “comfortable level”, especially in the

period from 9 to 16 hours.

Pic.1.The illumination dependence on time

Pic.1.The illumination dependence on time

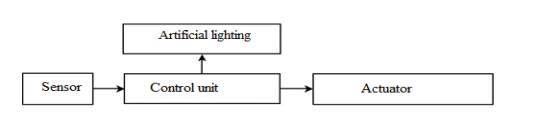

The purpose. Based on necessity of supporting the required level of light, it was

decided to create a device that would support the required level of light and

would be cheap enough for widespread implementation. The device consists of

three main functional units (excluding the power supply): unit conversion

parameter into electric light level setting (sensor); unit which processes the

receiving data of light level and controlsthe actuator and artificial lighting;

actuator and relay which turns on an artificial lighting, which functional

diagram is shown in the Pic.2.

Pic. 2.

Functional scheme

Sensory(touch)

block consists of two photoresistors FR12/100Ê (for

averaging).Received data about illumination level and control processing block

is based on MC ATmega 8. To convert photoresistors values into digital values are used two ADC channels

built into the MC. This block also includes power transistors to transfer from

5 volt MC signals to 15volt (they need for work of the executing

mechanism(actuator)), relay for turning on artificial lighting and indicator,

which is used for visual control of illuminating

level.

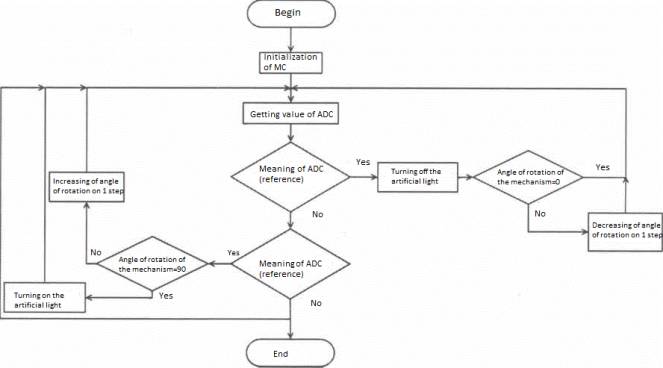

Flowchart

algorithm of work of the MC is shown on the pic. 3. [4,5]

Pic. 3. Flowchart algorithm of work of the MC.

As you can see on the flowchart, MC has easy algorithm of work: using

the ADC value, MC compares actual level of illuminating intensity with

references (standard level) and decide the direction of engine rotation and, as

a result, opening or closing blinds. It also turns on artificial light, if

blinds are completely opened, but actual level of illuminating is lower than

reference, or turns off artificial light, if blinds are completely opened and

actual level of illuminating intensity is higher than reference. The reference

light level is non-volatile and could be changed by user in any time.

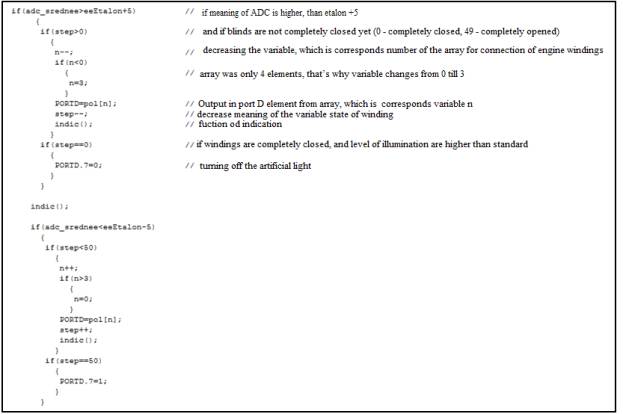

The executing mechanism (actuator) consists of stepper motor to rotate

the blind. Part of the program, which is responsible for control of executing

mechanism and relay of turning on artificial light is shown on the Pic. 4.

Pic. 4. Control of executing mechanism and

relay of turning on artificial light

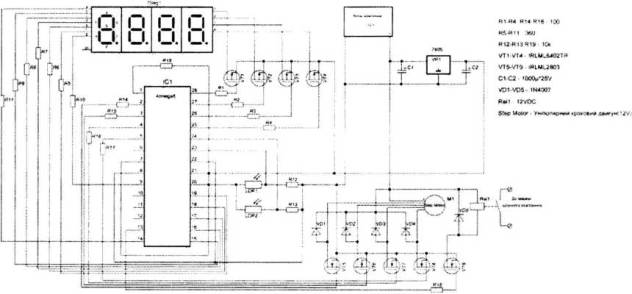

Let’s consider an

electrical key diagram of the device, shown on the Pic. 5. Resistors R1-R4,

R14-R18 reduce current difference overcharge of transistor locks (gate) VÒ1-VÒ9

when they are switched into opened/closed status. Resistors R5-R11 limit the

current of indicator segments. Resistors R12, R²Ç, LDR1 and LDR2 form tension

divider, which middle point is connected to ADC MC. Resistor R-19 reduce

probability of accidental reset of MC, which can cause electromagnetic

disturbances. Transistors VT1-VT9 used for switching indicator category,

windings of stepper motor and relay of artificial light, as they use more

current than MC could give. Also for approval tension of signals of MC and

power supply of motor and relay. Diodes VD1-VD5 protect the scheme from tension

emissions when switching motor and relay.

Pic. 5. An electrical key diagram of the

device

In the table number

1 are prices of components, which this device involve and its total value. [6-8].

Table 1

Prices of components and total value of the

device

|

Name |

Model/Characteristics |

Count |

Price for 1,hrn |

|

Indicator |

FYD-5622FS-11(general

anode) |

2 |

5,50 |

|

MC |

ATMEGA8A-PU |

1 |

22,00 |

|

Transistors: |

|

|

|

|

1) |

IRLML6402TR/20V;3,7A;SOT23 |

4 |

1.10 |

|

2) |

IRLML2803/30V;1,2A

SOT23 |

5 |

1,25 |

|

Stablilizer |

7805 CV/+5V,1.5A

TO220 |

1 |

1,55 |

|

Photoresistors |

FR

12/100k/6-18kOm 175 mW |

2 |

10,50 |

|

Resistors: |

|

|

|

|

1) |

100 Îm/SMD0805 |

9 |

0,08 |

|

2) |

360 Îm/SMD0805 |

7 |

0,08 |

|

3) |

10 kÎm/SMD 0805 |

3 |

0.08 |

|

Capacitors |

1000 µF*25

V |

2 |

1,25 |

|

Protectiondiodes |

LL4007/1À 1000VDO 213ÀÂ |

5 |

0,16 |

|

Powersupplyunit |

PW-12-2/12V 2À |

1 |

98,00 |

|

Stepper motor |

SY28STH51-0674A/Current of

winding-0.67 A. Retention time – 1200 g,cm |

1 |

250,00 |

|

Relay |

HLS-4078-DC12V-2C/HLS-4078-DC12V-2C |

1 |

8,50 |

|

Total |

|

|

427,52 |

Counclusions:

Economic profit. Using in rooms with two-three windows it is necessary only to increase

the number of engines and to add the unit with transistors, which are able to

let through more current. It allow store duce “specific” value of the device

for one window. But with the increasing of the number of windows, which blinds

are controlling from the one device, you need to consider hindrances, like

buildings, trees etc. more carefully.

Wideusingrange.This device can be used in

everyday life, offices, in high educational establishments, production rooms

etc. However it must be considered, that with increasing of linear dimensions

of the window, increases efforts, which is need for rotation of the slat of

blings.