Mel’nick V.N., Trivailo M.S., Karachun V.V.,

Mikul’onok I.O.

National Technical University of Ukraine “KPI”

THE BIOREAKTOR OF COMBUSTIBLE GAS

The utility model relates to biotechnology, namely, to equipment for

processing (recycling, disposal) of organic substances and can be used to

obtain gas from burning of waste from agricultural estates.

The known combustible gas bioreactor

(CGB) for waste of agricultural estates, which contains elastic in the form of

a bag reservoir for the anaerobic fermentation of organic waste in it,

supporting tank, hard case and located in the cavity of the reservoir mixing

device (see, Ukraine Patent for an invention ¹ 28685 , C 02 F 11/04, 2000).

The disadvantage of this CGB is insufficient strength of elastic

reservoir, which reduces reliability.

It is also known aCGB which contains fillable with processed matter

(biomass) metal case with technological pipes and compressor device for the

recirculation blow of body (see, À. ñ. ÑÑÑÐ ¹ 1715715, Ñ 02 F 11/04, 1992).

This CGB disadvantage

is that it does not provide control of temperature of processed biomass, that

slows down the activity of methane-cenerating bacteria and leads to lower

productivity.

As the closest to useful model at technical essence and reached effect

it is taken as the nearest equivalent CGB containing fillable with processed

biomass vertical cylindrical body with pressure relief pipe, massheater and

device for mixing, and covering body with the gap heat-insulating hermetical

jacket with gas sempler at the top and outside joined to pressure relief pipe

bottom (see, Ukraine Patent for an invention ¹ 70885, C 02 F 11/04, 2004).

The disadvantage of

known CGB is significant heat loss and increased dimensions in consideration of

joining of pressure relief pipe to the upper wall of the body and its external

position.

The basis of the utility model is a task to improve CGB, in which by

changing the joining of pressure relief pipe to the body and its location the

heat loss are eliminated and dimensions oh CGB are reduced.

A task is solved that in CGB, which contains fillable with processed

biomass vertical body with pressure relief pipe, heater and a device for mixing

and covering body with the gap heat-insulating hermetical jacket with gas sampler

at the top, according to a utility model the new is that pressure relief pipe

is joined to the bottom and body and is located with the gap concerning its

upper wall.

These distinctive features comparing with the nearest equivalent

eliminate tube contact with the surrounding environment that reduces heat loss

and dimensions. This improves the heating of biomass, especially the lower, the

coldest part that activates the vital activity of bacteria increases the

intensity of the made by them gas and improves productivity.

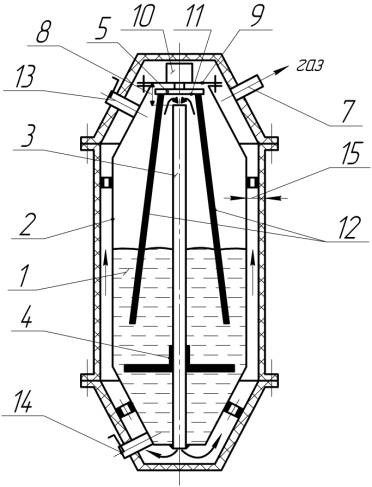

The drawing schematically shows announced CGB section (fig. 1).

Fig. 1

CGB contains fillable with processed biomass 1 vertical body 2 with

pressure relief pipe 3, heater 4 and a device for mixing 5 as well as covering

with the gap body 2 heat-insulating jacket 6 with gas sampler 7 at the top.

Pressure relief pipe 3 is connected to the bottom of body 2 and forms a gap 8

with its upper wall (cover) 9.

In the best performance pipe 3, on which it is fixed a heater 4, it is

desirable to produce of a material which has a larger than body 2 thermal

conductivity, such as aluminum, copper or brass, that promotes a more equitable

distribution of heat in the height of biomass in the tank.

Device 5 for mixing biomass 1 is fixed on the lid 9 of body 2 and

contains set on a shaft of gear-motor 10 disk 11with vanes 12 and body 2 has

closing nipples 13, 14 for a fresh and remove of the spent biomass.

The CGB works in next way.

Diluted with water

biomass is placed in body 2 and warm temperatures to 25-35 º C, after what

in definitive time anaerobic fermentation with gas emission appears there. Gas

generated by bacteria enters through the pipe 3 into gaps 15 between the body 2

and its jacket 6 and, partly giving heat to the lower parts of biomass 1,

removes through the nipple 7 for use.

As gas outlet pipe 3 contacts with the biomass 1, that is not present in

the nearest analogue, and transmits its accumulated heat with gas in the volume

of biomass, instead of transferring it to the air surrounding jacket in

analogue, so expenditure of energy for biomass heating (with heater) are

reduced. Thus, flowing through pipe 3, gas extra warms central parts of

biomass, that is also not present in the nearest analogue, resulting increasing

of evenness distribution of heat along height of biomass. Increase of

uniformity of heat along the height of biomass intensifies its processing of

bacteria, that increases gassing and therefore productivity.

Reducing of heat loss and reduce of the size while increasing

productivity increases the efficiency of CGB.