Engineering

sciences/12. Automated

control systems in manufacturing process

Ph. D. Borovska

T. N.

Vinnitca National Technical

University, Ukraine

Constructing of

innovative development models

Introduction. Innovative development is proved to be the necessary

condition of survival for production systems of any scale. It is known that

since 80s, Japan has spent on innovations and scientific research fractions of

percent more than the USA. By the year 2000 the USA had abandoned the own

production of some types of electronic equipment, the share of Japanese cars

had drastically grown on the markets of the USA. Today effective innovative

strategy is carried out by the organizations of India and China. Quite natural

practical problem regarding optimal distribution of resources of production

facilities between proper production and innovative developments arises.

Formulation

of the problem, dealing with the elaboration of innovative development models. The purpose of the given research is to elaborate the extended mathematical model of the production system taking into account the development of innovations, creation on their basis of new products and means of production,

manufacturing of the constantly renovated industrial

products on systematically updated production capacities. Classic approach

to the construction of innovative development model – from statistics, experiments, approximations - is unproductive or impractical for the production systems. At the initial stages innovation

does not have any statistics. G. Forrester

offered and realized in simulation models of an enterprise and city another

method of construction of the model of a large system – from credibly revealed

regularities of functioning and development of large systems. Statistics

is applied at the stages of verification of the model.

Ways

of

problem solution. In sufficiently large production systems usually there are subdivisions,

engaged in research and development of new products, technologies and equipment,

subdivisions, engaged in modernization and creation of production capacities,

and subdivisions, producing the finished goods. In the model of the first approximation

we consider the production system, consisting of three subsystems:

"innovations", "development", "production" [1, 2].

In the following approximation it is possible to examine the

"incomplete" production systems, buying the equipment and

technologies, consider the processes of innovations distribution, etc. We

assume the existence in each subsystem of stochastic dependence "resources

– product", average of which is reduced meets to nonstrict

monotonous and nonstrict positive limited dependence - generalized production

function. Choice

of basic model structure of the

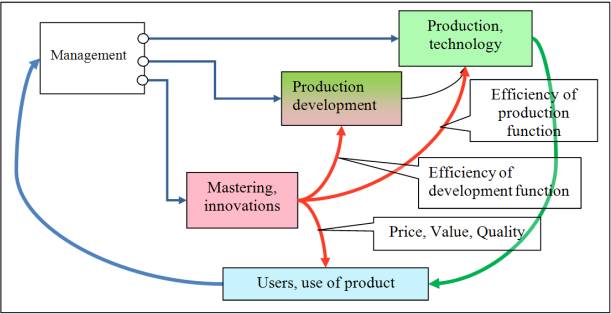

production system. In Fig. 1 the diagram of the production system is presented taking

into account its development.

Fig. 1. Diagram of the production system

Basic

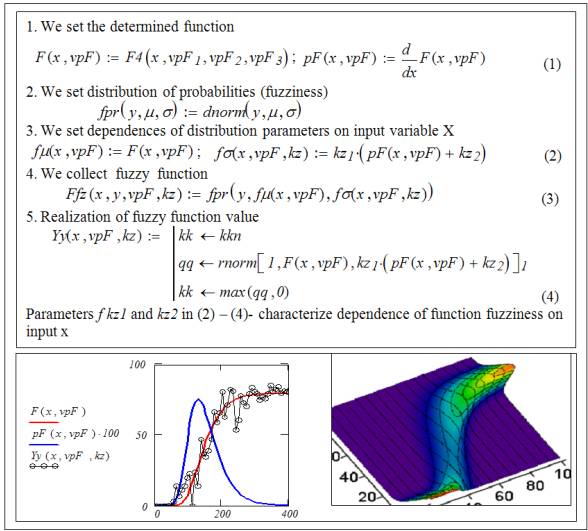

model of generalized production function. In the

first approximation we consider the set states of models of functional subsystems

- innovations, development, production. In Fig. 2 an «informative block» – working

mathematical model and results is presented. In the debugged model it is simple

to enter inertia, delay, effects of utilization and saturation of necessities.

The specific feature of manufacturing of «product» in these subsystems is

different, however, general «mechanisms» and properties allow to build basic

parametric model, which can be adjusted on the specific feature of subsystems

of «innovation», «development», «production». Basic model is realized in the environment

of mathematical package

Operators

of parametrical connections in the system of "innovation, development,

production". The most difficult for formalization element of three -level

production system is connections between subsystems (Fig. 1).

Fig.

2. Basic model of generalized production function

To be more precise, it is transformation of the

output of the previous subsystem in the changes of production

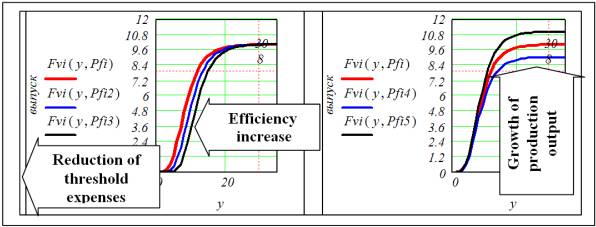

function ( PF) of the following subsystem. For example, the subsystem «development»,

having spent dY resources, modified the subsystem «production», that led

(Fig. 3):

- to the increase of production capacity A by dA;

- to the increase of «steepness» of production function a by the value da;

- to the decrease of threshold (permanent) expenses s, by ds.

We will consider the scenarios of realization of the changes of

"production" subsystem: - scenario 1: simple expansion of production

- machine-tools, reactors, workplaces operate in parallel; - scenario 2:

reduction of production expenses - variable and constant without a change of

production capacities.

Fig. 3. Changes of production function of the

developing system

We will consider more suitable for formalization scenario of small continuous

changes. The statement of generalized PF change

can be presented in the form:

![]()

where ![]() ,

, ![]() are the states

of PF,

are the states

of PF, ![]() are increments

of PF,

are increments

of PF, ![]() is an

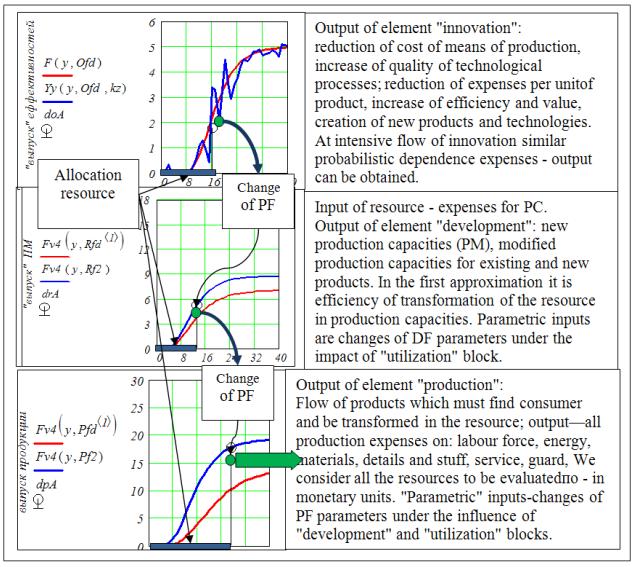

operator. Complex nonlinear connections of nonlinear systems caused the necessity

of creation of stand for research and better understanding of the essence of

innovative development. Part of stand is presented in Fig. 4.

is an

operator. Complex nonlinear connections of nonlinear systems caused the necessity

of creation of stand for research and better understanding of the essence of

innovative development. Part of stand is presented in Fig. 4.

Generalization of the results.

The problem is solved – basic working model of innovative development of the

production system is constructed. The next stage is to construct on the base of

verisimilar and operational concept a working tool. We will consider the

alternative variants of the programmatic module «chain»:

- ![]() is a function which takes the functions of

innovations, development, production, total resource and returns the volume of

output of end products and new functions of development and production;

is a function which takes the functions of

innovations, development, production, total resource and returns the volume of

output of end products and new functions of development and production;

- ![]() is a function which takes the parameters of

functions of innovations, development, production, total resource and returns

the output of end products and new values of PF parameters. Exactly this function

is used in the example in Fig. 4. On the base of these functions it is possible

to realize:

is a function which takes the parameters of

functions of innovations, development, production, total resource and returns

the output of end products and new values of PF parameters. Exactly this function

is used in the example in Fig. 4. On the base of these functions it is possible

to realize: ![]() optimum equivalent production function of the

system "innovation, development, production", which takes the

structure of vRs, consisting of the

interval of the system resource change, its initial distribution; matrix of

parameters of production functions of subsystems Mpse and a number of steps K,

and returns dependence of end products output of the system on the total

expenses on condition of optimization of resource distribution between

subsystems.

optimum equivalent production function of the

system "innovation, development, production", which takes the

structure of vRs, consisting of the

interval of the system resource change, its initial distribution; matrix of

parameters of production functions of subsystems Mpse and a number of steps K,

and returns dependence of end products output of the system on the total

expenses on condition of optimization of resource distribution between

subsystems.

Fig.

4. Stand for the analysis of the system «innovation, development, production»

Fig.

4. Stand for the analysis of the system «innovation, development, production»

On the base of function Op3 of

the three-level system it is possible to put forward and solve variational

problem of optimal development during certain planned period. Another direction

of function Op3 application: it is possible to obtain the influence functions of

subsystems «innovation», «development» on the

production.

Referenses

1. Áîðîâñüêà Ò. Ì. Ìåòîä îïòèìàëüíîãî

àãðåãóâàííÿ â îïòèì³çàö³éíèõ çàäà÷àõ: ìîíîãðàô³ÿ / Ò. Ì. Áîðîâñüêà, ².Ñ. Êîëåñíèê,

Â.À. Ñåâåð³ëîâ.

– ³ííèöÿ: ÓͲÂÅÐÑÓÌ-³ííèöÿ, 2009. – 229 ñ. – ISBN 978-966-641-285-3.

2. Ìîäåëþâàííÿ

³ îïòèì³çàö³ÿ ïðîöåñ³â ðîçâèòêó âèðîáíè÷èõ ñèñòåì ç óðàõóâàííÿì âèêîðèñòàííÿ

çîâí³øí³õ ðåñóðñ³â òà åôåêò³â îñâîºííÿ: ìîíîãðàô³ÿ / [Áîðîâñüêà Ò.Ì., Áàäüîðà Ñ.Ï.,

Ñåâåð³ëîâ Â.À., Ñåâåð³ëîâ Ï.Â.]; çà çàã. ðåä. Ò.Ì. Áîðîâñüêî¿. – ³ííèöÿ: ÂÍÒÓ, 2009. – 255

ñ. – ISBN 978-966-641-312-6.