Gushin A.M., Oleynik I.N.

Donbass State Machinebuilding Academy

CARVING

AND ENGRAVING ON FUNDAMENTALLY NEW TEHNOLOGIES

![]()

Aspiration to reduce the

terms of creation of works of art by mechanization and automation of the

protracted hand operations and on the whole expensive treatment of intricate

articles, including unique ones, to create new technological equipment for the

acceleration of labor intensive preliminary operations of treatment of original

articles, including those made of rare materials, resulted in the idea of

creation of machine-tools for a carving and engraving on any materials and,

above all things, jewels, eliminating the labor intensive handwork of an artist

at all stages of rough operations, taking more than 80% of carver’s time to do

his work, but at the same time giving a possibility for realization of creative

potential of a man on adjustment and interference with the process of making an

article at any stage of its production.

Aspiration to reduce the

terms of creation of works of art by mechanization and automation of the

protracted hand operations and on the whole expensive treatment of intricate

articles, including unique ones, to create new technological equipment for the

acceleration of labor intensive preliminary operations of treatment of original

articles, including those made of rare materials, resulted in the idea of

creation of machine-tools for a carving and engraving on any materials and,

above all things, jewels, eliminating the labor intensive handwork of an artist

at all stages of rough operations, taking more than 80% of carver’s time to do

his work, but at the same time giving a possibility for realization of creative

potential of a man on adjustment and interference with the process of making an

article at any stage of its production.

It must be agreed with the

well-known English researcher of Faberzhe creative work K Spowman who said that

“the most gifted modern masters waste their capabilities and talent on the

decision of the question how to make more, quicker, and cheaper ”. Sculptors

and artists have been working this way for ages.

Analizing the creative

heritage of MichelangeloIrving Stown notes what sufferings the great artist

felt creating his masterpieces, and no less tormenting his thoughts were when

he realized the impossibility of implementing his ideas even working 14 hours a

day.

Analizing the creative

heritage of MichelangeloIrving Stown notes what sufferings the great artist

felt creating his masterpieces, and no less tormenting his thoughts were when

he realized the impossibility of implementing his ideas even working 14 hours a

day.

![]() Therefore

we shall dwell on the detailes of production technologies of high-quality

carved articles made of wood, bone, semiprecious and precious stones,

simultaniously estimating the necessity of mechanization of labour-intensive

hand operations, especially preliminary made by a sculptor with a great amount

of muscular energy.

Therefore

we shall dwell on the detailes of production technologies of high-quality

carved articles made of wood, bone, semiprecious and precious stones,

simultaniously estimating the necessity of mechanization of labour-intensive

hand operations, especially preliminary made by a sculptor with a great amount

of muscular energy.

Preconceived opinion, as though a sculptor or a carver

is under an obligation to execute his work with his own hands, took a root in

the minds of our contemporaries so deeply, that made them forget the following:

neither the temples of India, neither Egyptian sphinxes nor portals of gothic

cathedrals, are the fruit of hands of their creators. These are the hands of « marble masons »,

so-called the craftsmen who incarnated in material the ideas of authors of the works of arts.

One of the stained-glass windows in Shartrsky Cathedral

is devoted to the art of carvers on stone,

here the author is represented in a laurel wreath - he manages the workers,who treat

a sculpture lying on the ground.

In fact creation is an essence of art, and every

technology presupposes handicraft, routine. However transition from a unique

art, accessible to talented individuals, to mass art, reproduced by

technologies, is typical for all of kinds of human activity. Suffice it to

remember the typographical and other printing of books. Somehow nobody doubts

whether the photocopying of such kind is necessary.

Therefore

the offered «three-dimensional xeroxes» are copying machine-tools, to which any

material is subjected, will enter our everyday life like the well-known photocopying

equipment.

Therefore

the offered «three-dimensional xeroxes» are copying machine-tools, to which any

material is subjected, will enter our everyday life like the well-known photocopying

equipment.

![]() As it is generally known,

creating the model of future

work of art, sculptors and

carvers use clay, plastic, beeswax. It is clear, that any slips, errors on such

materials are easily removed and the master can easily achieve the desired

result. Further the work is necessary to be executed in material and now the

artist has to work very hard.

As it is generally known,

creating the model of future

work of art, sculptors and

carvers use clay, plastic, beeswax. It is clear, that any slips, errors on such

materials are easily removed and the master can easily achieve the desired

result. Further the work is necessary to be executed in material and now the

artist has to work very hard.

V. Pikul' describes the process of engraver’s work:

«Laval set to work. Engraving replaced a picture in the days of old(before

1812), because it was possible to make a great number of prints from one board.

But labour is not easy, it needs unprecedented exactness of gesture and large

physical force. A hand leads a chisel on a metal, leaving a furrow on it, one

incorrect motion — and all work (sometimes the work of all the life) flies on a

rubbish heap. A writer, having written an incorrect word, can cross it out; a

painter, having put an incorrect light on the picture can paint it out; an engraver

cannot correct anything - a chisel firmly sticks in a metal and all depends on

the ability of the engraver».

![]() The

ideas of copying treatment have always

been and have been realized by different masters in one way or another. For

example, after preparatory sketches from which only a

small number was saved, Mikelandzhelo

passed to making small models from clay or beeswax.

The

ideas of copying treatment have always

been and have been realized by different masters in one way or another. For

example, after preparatory sketches from which only a

small number was saved, Mikelandzhelo

passed to making small models from clay or beeswax.  Frequently,

he did not confined himself to creation

of small models, more frequently he made them as the future sculptures of a

real size.

Frequently,

he did not confined himself to creation

of small models, more frequently he made them as the future sculptures of a

real size.

B. Chellini in his «Treatise about a sculpture» wrote:

«In order to execute a sculpture in marble well... a good master must make a

little model, not more than two spans, and then decide in it the pose of figure, dressed or bare... Then it must be increased as

much as it will be in marble...».

These words are

convincing enough in favour of photocopying machines because acording to the

technology offered they, for example, can copy a work of art from wax or

plaster model with an accuracy of 0,02 mm with any material not depending on its

hardness or other physical-mechanical properties. And if it is indeed a

beautiful thing – copy it, give people the beauty!

![]()

The

innovations offered for realization by this project fall into the category of «know-what»

and cover a wide range of application. These technologies are executed at the

level of science intensive

high-tech, involving the ideas of more than twenty registered inventions which are

going to be patented. Thus, the

introduction of the newest technologies on mechanization of hand labour

intensive operations at creation of exclusive hand-made products is very problematic.

The

innovations offered for realization by this project fall into the category of «know-what»

and cover a wide range of application. These technologies are executed at the

level of science intensive

high-tech, involving the ideas of more than twenty registered inventions which are

going to be patented. Thus, the

introduction of the newest technologies on mechanization of hand labour

intensive operations at creation of exclusive hand-made products is very problematic.

Therefore, the

appearance of completely new technologies of mechanization and automation of

hand labour intensive operations on treatment of materials with any hardness

can substantially influence the balanced market of artistic works made of

expensive materials, machine-tools and tools for their treatment.

Work in the area of creation of copying «machine-tools

working

marble” started

in 1970 from creation of fundamentally new designs of drives of technological

machines. This area of science was called «mechanotronics », because at that

time nobody knew about the works of Japanese researchers, who gave the world the idea of « mechanotronics ». Presently, not claiming the

priority, the authors decided to leave the name «mechanotronics », seeing in it

small, but distinctive features.

![]()

As an object of investigation the linear engine of

direct current, in which the armature does not rotate, but accomplishes the

reciprocating motion, was chosen. Positive results (patent of the USSR) were obtained

in 1972, new tendency in designing «mechanisms», imitating the actions of a

man, being discovered at once. With the

help of the complex technical innovations it became possible to weigh the

hollow mobile armature of the linear electric engine in the magnetic field and

make it move on a “magnetic pillow”.

As an object of investigation the linear engine of

direct current, in which the armature does not rotate, but accomplishes the

reciprocating motion, was chosen. Positive results (patent of the USSR) were obtained

in 1972, new tendency in designing «mechanisms», imitating the actions of a

man, being discovered at once. With the

help of the complex technical innovations it became possible to weigh the

hollow mobile armature of the linear electric engine in the magnetic field and

make it move on a “magnetic pillow”.

Thus, a «contactless mechanism» was obtained. The

efforts are transmitted not by the direct contact of the interacted parts but

with the help of the magnetic field

created in the clearance between these parts.

On principle new properties of the « contactless mechanism»:

• Practical absence of forces of friction (friction on

air of a mobile element);

• High exactness and dynamic characteristics;

• Exceptionally high controllability.

The “mechanisms” of such kind by their character

(control of electric current without intermediate elements) are easily

connected with computers and allow to solve the problems which cannot be solved by traditional machines. The tracking drives of technological

machines have been produced. They increased, in one order and even more, the

spead of machine-tool reaction on the changing conditions of working that made

it possible to synthesize qualitatievely new methods of cutting metalls and

other materials, the accuracy in which is formed beyond the limits of

machine-tool kinematics and does not depend on the accuracy of the latter.

Further investigations in this area resulted in the

idea of creation of wide class of machines, the behaviour of executive parts of

which would adapt to the

external environment conditions (largely indefinite).

During the subsequent years on the base of new ideas a

number of complex technological

problems has been decided, the solution of which is connected with great expenses with application

of traditional technique or

in general with impossibility of their realization.

At the same time a considerable part of research was devoted to

modernization of the existing NC machine-tools with the purpose of giving them new

qualities, in particular shifting machines to adaptive mode of operation as

well as creation of original designs of devices to connect microcomputers with

technological machines.

As a result of long-term experiments, conducted in the

Donbas State Machine-building Academy (Kramatorsk, Ukraine), it was succeeded

to create on principle new copying-milling-grinding machine-tools, operating

automatically on any materials, including single-crystals with hardness 9–9,5

on the Moths scale (separate units of a machine-tool are protected by 12

author’s certificates of the USSR).

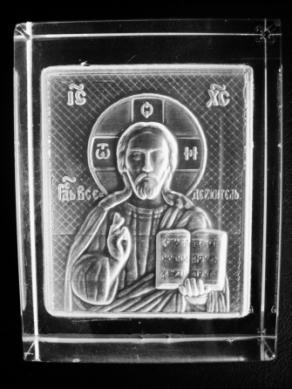

Simultaneously with the creation of machine-tools the

designes of original tools have been perfected, technologies of carving and

engraving on wood (picture.1), bone(picture 6), combination “wood-bone”(picture

7), marble (picture.2), optical glass (picture.3), and also on precious stones (picture.4 – made of

leucosapphire), have been developed.

![]()

At the same time the

work on modernization of vertical-milling machines with NC was going on. The

purpose was to expand their technological potentialities, that is to give them

new qualities – possibilities of treatment of materials having any physical-mechanical

properties without man’s interference with the process of treatment (picture.4,

picture.5 are computer graphics on a machine-tool with polishing).

At the same time the

work on modernization of vertical-milling machines with NC was going on. The

purpose was to expand their technological potentialities, that is to give them

new qualities – possibilities of treatment of materials having any physical-mechanical

properties without man’s interference with the process of treatment (picture.4,

picture.5 are computer graphics on a machine-tool with polishing).

The ideas

of modernization of any existing metal-working equipment with numerical control

with the purpose of expansion of their technological capabilities in terms of

extra-hard and hard-working materials have been realized.

The most perspective for modernization are

machine-tools of firm Roland DG (Japan) series of MDX-20/15 – MDX-500, involving

all the latest achievements in information technologies, mathematical modeling,

computer technique and science on the whole.

Together with 3D

scanners, for example, of series of PICZA, LPX-250,

LPX-1200(Japan), which can scan objects of a human hair thickness, digitizing

all of nuances of initial sample (on these devices it is possible to scan glass

and any transparent materials, and as well as plasticine figures, berries and

other soft objects with unprecedented precision), it is possible to get automatically

mathematical models and programs for NC-machine-tools, and then on the same

modernized machine-tools one can get masterpieces made of semiprecious and

precious stones.

For the aims of artistic stone

treatment the engraving-milling equipment of firm Woodpecker(THE USA),

which includes a series of machine-tools from the jewelry working to the giant

machine-tools with the area of working

1400х3020 mm is also suitable. Monumental works of art can be machined

on this equipment.

Laser engraving machine-tools, for example, of firm

Argus (China), together with above-mentioned NC-machines, will allow to create

fundamentally new technologies of stone-cutting art, that are beyond the powers

of man’s hand. (picture.4 is an example of

laser engraving on leucosapphire).

For realization of new ideas of carving and engraving

on stone and other materials the

machine-tools of firm ShopBot CNC Tools (THE USA), of Mell series after

modernization suit perfectly well.

Thus, eliminating labor intensive hand operations at

all stages of treatment of articles in material, new technologies give

wonderful possibility for realization of creative potential of Master. From now

on while creating a future work of art, a carver or a sculptor is to create his

model in readily-working material – wax, plasticine, clay, etc.

The technologies

developed in the Donbass State Machine-Building Academy open new prospects:

§ creation of unique works of art from materials with any

physical-mechanical properties;

§ the offered technologies will allow to release an artist from routine

work, leaving him the possibility of creative realization of his ideas;

§ sharp reduction of terms from the origin of an idea to realization of the

work of art;

§ diminishing of cost of unique works of art, that will make them

accessible for the various strata of society.

Small machine-tools of

completely new design can work in the conditions of home workshops and small

enterprises, that will provide appearance of additional workplaces, including

for socially unprotected levels of population, in

particular, invalids, pensioners, students, schoolchildren.

Donbas State

Machine-Building Academy is opened for a wide collaboration with the purpose of

introduction of «know-how» into the national economy of Ukraine and other countries.

REFERENCES:

1.

Т. Исли, И. Симояма, Х. Иноуэ, М. Хиросэ, И. Наладзима Мехатроника// Москва,

Мир, 1988.

2.

А.М. Гущин и др. Станок для копировальной обработки// Авторское свидетельство

СССР №1389992, В23, Q35118, Бюл№15, 1988.

3.

А.М. Гущин и др. Копировальный станок// Авторское свидетельство СССР №997999,

Бюл№7, 1983.

4.

И.В. Стешенко и др. Линейный электродвигатель//Авторское свидетельство СССР №SU1427512,

Бюл№36, 1988.