Olga A. Sharaya

(Karaganda State Technical University, Kazakhstan)

Steel

hardening by laser exposure

Mechanic parts and mechanisms are in

most cases exposed to high thermal and mechanic stresses as well as to

chemically active and abrasive elements. Increasing their life time may be

obtained by modifying the surface, that is forming coats or layers on the parts

with enhanced properties required.

One

of the prospective ways of steel surface hardening is laser hardening. As

compared to the traditional methods of thermal treatment, laser hardening

provides for increased hardness and wear-resistance of carbonaceous and alloyed

steels, minimum deformations, a possibility of local hardening of work surfaces

and an automated process.

This

work has studied the impact of uninterrupted laser radiation on the structure

and properties of 45 steel. Laser treatment was conducted on the HEBR-2500

technological CO2 laser. Sample treatment modes were chosen as to

avoid weld penetration of the surface.

The

main parameters conditioning the experiment's final results are the density of

laser radiation capacity (S) and the speed of sample treatment (ν). Capacity density is responsible

for the size of the weld penetration area and the rightly adjusted speed of

treatment allows to harden without considerable surface melting.

The

density of laser radiation capacity was calculated with the formula below:

![]()

where as Ð

is the laser radiation capacity, Wt, and d is the spot diameter, mm.

The

first bunch of samples was exposed to hardening with the following parameters:

laser radiation capacity P = 500Wt; sample treatment speed ν = 520 mm/min; laser head height I = 1, 5, 10, 15 mm.

The

surface weld penetration has been satisfactory, but the air current which cools

the lenses, inflates the melted layer of metal and grooves 1.5 mm deep are

formed on the surface of samples on both sides of the hardened area. Increasing

the height of the head above the sample and the capacity led to the increased

size of the treated area, which is not always desirable, so in further

experiments the speed of treatment was increased.

The

second bunch of samples had the following parameters: Ð = 500 Wt; ν = 1400 mm/min; I = 1, 5, 9, 12, 15 mm. The first three samples of the second bunch also saw the formation of

grooves, but with the height of the head exceeding 10 mm the dispersion of melt

did not take place.

In

practice, whenever it is required to treat the surface without melting,

absorbing coatings are used. The wave length of the HEBR-2500 laser radiation,

which is 10,6 mkm, is almost fully absorbed by the aluminium oxide Al2O3,

so for the third bunch of samples the absorbing coating based on the aluminium

oxide mixed with the 4C varnish was used.

Samples

with the absorbing coating were treated under: P =

500 Wt; ν = 1400 mm/min; I = 1, 5, 9, 12, 15, 18 mm. It is

typical to observe melted grooves in case of the small height of the laser

head: I = 1 and 5 mm, but their maximum depth was only 0,4

mm. In other cases, the radiation burned through the coating, but the surface was not deformed, which means that there was no melting area.

The metallographic and

micro-durometric analyses were conducted on the METAVAL optical microscope with

an add-on for micro-hardness measurements.

The analysis of final

results showed that the hardened area depth in samples with melted surfaces was

at the level of 200 mkm without such melting.

The maximum

micro-hardness of the hardened area in samples where the hardening had been

conduced with surface melting, was 12900 MPa, in no-melting samples it was

10400 MPa and in absorbing coating samples it reached 7000 MPa whereas the

basic micro-hardness was 1800-2000 MPa.

The

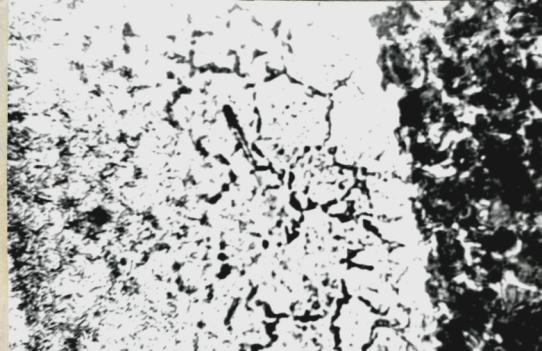

microstructure of 45 steel after laser hardening is given in Picture 1.

Picture 1. 45 Steel Microstructure, 100x

The surface layer of 45

steel samples after laser hardening with melting consists of four areas: the

melted layer 10-300 mkm deep with micro-hardness up to 10000 MPa made of

martensite with a small quantity of residual austenite; the hardened layer

70-100 mkm deep with micro-hardness of 10000-13000 MPa made of martensite with

needles twice bigger that in the first area; the transit area 60-80 mkm deep

with micro-hardness of 4000-4500 MPa made of martensite and the ferrite grid

and ferrite-pearlite basis of 45 steel. No-melting samples had not only the

melted area.

The distribution of

micro-hardness along the depth of the hardened layer shows that the maximum

values of micro-hardness have been observed at a certain distance from the

surface (in the second area), and afterwards are followed by a smooth decline

down to the initial values of 45 steel corresponding to 1800-2000 MPa (see

picture 2).

![]()

Picture 2. Distribution

of micro-hardness

along the depth of the hardened layer

● – with surface melting;

■ – without surface melting;

▲ – with absorbing coating.

The

practical studies managed to figure out optimal modes for 45 steel laser

hardening.