Karachun V.V., Trivailo M.S., Mel’nick V.N.

National Technical University of Ukraine “KPI”

THE CULTURING CELLS IN LIQUID

MEDIA

The

utility model relates to biotechnology and can be used for culturing cells in

the production of vaccines and a variety of biologically active drugs.

Known

apparatus for culturing cells (DÑC), comprising a

cylindrical body with technology and Cantilever pipe fixed on the bottom shell

reshuffle drive with nonmagnetic materials, and drive in the form set out in

the rotor disk and periodically interacting magnets (see for example A.S. USSR ¹1306944,

Ñ 12 Ì 3/00, 1987).

The

disadvantage of this DCC is low efficiency of mixing, due to the console and

drive consolidation serves the cause of performance degradation.

The

most useful model close to the technical essence and dosyahayemym effect is taken

as a prototype of the DCC, which contains the vertical cylindrical body with a

lid and technological pipe reshuffle device as a rod with a disc of magnetic

material and the drive rod in the form of uniformly arranged in a circle in the

bottom case consistently connected to power electromagnets (see., patent of

Ukraine for utility model ¹12120, C 12 M 3 /

00, 2006).

The

main disadvantage of the famous DCC is existing damage to cells due to

mechanical friction during the cultivation due to the location of support

surface mixing device in the volume of fluid, which reduces the quality of cultivation

and conformity of the finished product.

The

basis of the utility model a task to improve the DCC, which means the location

of surface friction, mechanical stirring device outside the working fluid is

removed damaged cells cultivated serving quality.

A task

is solved that in the DCC, which contains a vertical cylindrical body with a

lid and technological pipe reshuffle device as a rod with a disc of magnetic

material and the drive rod in the form of uniformly arranged in a circle over

nosed drive consistently connected to power electromagnets under the new

utility model is that the core hinges attached to the center of the lid, and

lid made of nonmagnetic material.

These

distinctive features, unlike the prototype, eliminate mechanical friction and thus

damage his cell in the process of cultivation that leads to an increase in

quality.

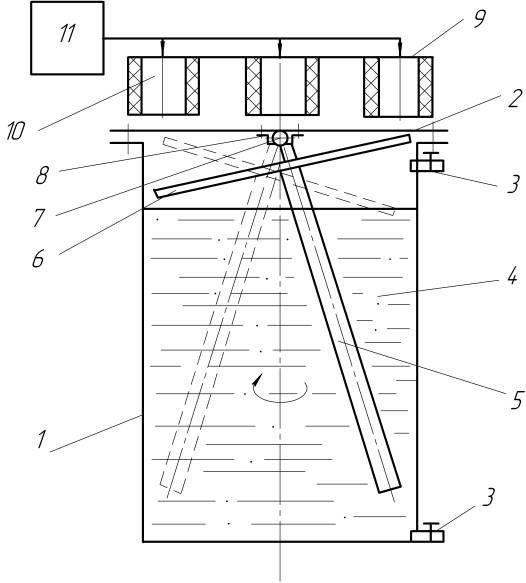

The

drawings show claimed DCC (fig.1).

Fig. 1.

DCC has

vertical cylindrical housing 1 with lid 2 with non-magnetic material and

technological pipe 3 to enter and remove cultural (working) fluid 4. In case 1

set reshuffle device type of bar 5 with pressed on it and made of magnetic

material disc 6. Bar 5 joint added an overhead end to the center of lid 2, for

example, by the spherical tailpress foreseen for this purpose 7 with a holder

8, or by known another way. On a lid 2 the set occasion 9 in form equispaced on

a circle above the overhead butt end of disk 6 electromagnets 10, which in the

programmatic pulse-mode are connected consistently to the source of feed 11.

Except for round, mixing bar 5 can have flat or other known geometrical form.

DCC

works as follows.

At

including of electromagnetic occasion 9 electromagnets 10 form the rotary-type

magnetic field which attracts a disk 6, as a result it comes in a sinewave, and

the bar connected with it 5 – in circulating motion about axis of corps 1.

Revolved, bar 5 carries out active interfusion of working liquid 4.

Being

in suspended to the lid 2 states, in place of benthic location in a prototype,

mixing bar 5 and it drive disk 6 does not create the working liquid of 4 areas

of mechanical friction in a volume, and that is why inevitable damage them of

cages at cultivation, as it takes place in a prototype, and it results in

growth of quality.

Except

for it, a construction is simplified, as a corps acquires form of one detail,

in place of two details in a prototype.