Tereshatov

V.V., Makarova M.A., Slobodinyuk A.I., Vnutskih Zh.A.

Institute of Technical Chemistry Ural

Branch Russian Academy of Science,

Perm, Russia

Prospective segmented elastomers with diverse

urethane and urethane urea hard segments

Polyurethanes

are a unique class of polymers which structure and properties are regulated in

wide limits due to using of various polyols, diisocyanates and chain extenders

at synthesis. Polyurethane materials with different combination of properties

can be obtained depending on chemical structure and quantity of components

[1-2].

Segmented

polyurethanes (SPU) consist of alternating soft and hard segments (blocks) of

different chemical structure and polarity. Chemical structure of soft segments

of SPU is determined by structure of olygomers used for their synthesis [3-5].

Hard segments are formed at the reaction of diisocyanate with

low-molecular-mass bifunctional compositions, for example diols or diamines.

Investigation

of oligodiisocyanates mixes on the base of various oligomers allows to expand a

rang to regulate properties of SPU. It

was shown that elastomers with diverse soft segments can significantly exceed

block-copolymers on the base of individual oligodiisocyanates [3,4], for

instance, for strength and moisture resistance.

The

behavior of SPU with diverse hard segments is still poorly investigated. Hence new

combination of properties of such materials could be expected while using mixes

on the base of low-molecular-mass diamine and diol as hardener for prepolymer.

This work

presents results of the investigation of the behavior regularities of segmented

elastomers (SE) with the same polyether soft segments and diverse hard segments

(urethane and urethane urea ones).

The aim

of the work is development of properties of heterogeneous segmented elastomers

with hydrogen bonds.

The table

presents data on the physical-mechanic properties of SE at the strain rate 0.28

s-1, the glassing transit temperature of the soft phase Ògs, and the softening

temperature of the hard phase Th

for various molar concentration of methylene-bis-orto-chloroaniline (MOCA) õ1 in the mix with Butanediol-1,4 (BD) used within

the synthesis of polymers.

Table. Properties of SE with urethane and urethane

urea segments

|

õ1 |

fp, MPa |

lð |

Å100, MPa |

Tgs, °C |

Th, °C |

Ch, % |

|

1.0 |

248 |

5.58 |

14.7 |

-51 |

202 |

36.6 |

|

0.8 |

274 |

5.87 |

11.4 |

-50 |

202 |

35.2 |

|

0.7 |

307 |

6.16 |

9.5 |

-48 |

199 |

34.5 |

|

0.5 |

360 |

6.42 |

7.2 |

-44 |

193 |

33.0 |

|

0.4 |

278 |

6.64 |

5.4 |

-41 |

185 |

32.3 |

|

0.3 |

201 |

7.02 |

3.4 |

-40 |

173 |

31.6 |

|

0 |

114 |

10.10 |

1.9 |

-37 |

- |

29.1 |

It is evident

that properties of investigated materials are significantly changed. For

example, the ultimate strain ratio changes in 2 times, the conventional elastic

modulus Å100 changes more than in 7 times in the range of the molar fraction õ1 of MOCA in the mix

with BD (from 0 to 1). The total concentration of hard blocks (urethane and

urethane urea ones) in investigated materials varies a little. The composition of hard blocks influences the

properties of SE in the higher degree. The low content of urethane urea hard blocks

(õ1>0.5) leads to

increase in the glass transit temperature of the soft phase, and decrease in

the glass transit temperature of the hard phase. This effect may be a result of

formation of the more defect friable structure.

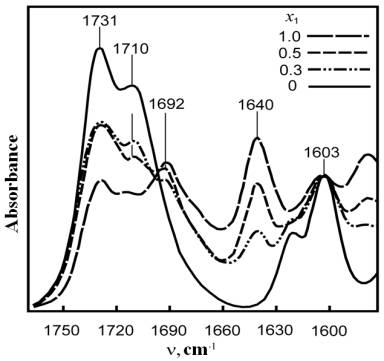

An analysis of IR-spectra

of SE shows that increase in fraction of urethane segments in the composition of diverse hard segments leads

to increase in the intensity of the band at 1710 cm-1 for vibration of carbonyl of urethane groups bonded with ether oxygen via H-bonds. This confirms the increase of fraction of urethane hard blocks in the soft phase of a polymer. In the ultimate case

(õ1=0) two bands can be

seen for carbonyl: the band for free carbonyl at 1731 ñì-1 and urethane group absorption band (1710 cm-1)

associated with the H-bonded oxygen polyester. The band 1700 – 1731 cm-1

for carbonyl of urethane groups’ self-associates bonded by H-bonds is absent.

Thus, the material has only a one phase with presence of urethane hard segments

only (Fig. 1).

Fig. 1. IR-spectra of SE with various fraction of aromatic

diamine in the mix with Butanediol-1,4.

An intensive

absorbance band of carbonyl of self-associates of urea groups at 1640 cm-1 shows

that the degree of microphase separation between soft polyether segments and

hard urethane ones is high while õ1=1 (Fig.1). The assignment of bands was made according to [6].

The glassing

transit temperature of the soft phase Ògs should increase and

the Å100 value decrease because

solubility of hard blocks in the soft phase of SE increases as the fraction of BD

increases in the mix with MOCA at the synthesis of a polymer. This effect is

shown in experiments.

The maximum

true tensile strength fp of SE is shown at the same fraction of

urethane and urethane urea hard segments in them (õ1=0.5). This value

is higher the same for the classic polytetramethylene oxide urethane urea in 1,5

times. The high tensile strength of SE is combined with the significant

increase in the ultimate strain ratio lð of a material (Table).

|

Figure

2 shows an inverse relationship of the true tensile strength fp on the strain rate u for polyurethane

urea (õ1=1) and SE with the same fraction of urethane and urethane urea

blocks. According [6, 7]

this effect relates to the process of strain of hard blocks when they don't

have time to orient in the strain direction at the high rates. Decrease in

this rate leads to increase in the orientation degree of hard blocks at high

strain ratios, this allows to increase the tensile strength of SE. |

|

|

Fig. 2. True

tensile strength versus strain rate for SE:1 – with diverse hard blocks (õ1=0.5), 2 – without urethane blocks (õ1=1). |

On the

contrary, relaxation of labile physical network allows to decrease in tensile

strength of a material. The influence of the orientation factor of hard

segments on the strength of SE leads to the great difference between maximal

and minimal value of strength fp (in 1.7 times). Interchain

interaction is amplified in the soft phase of SE when one half of urethane urea

hard blocks replaced by urethane ones, soluble in the soft phase of a polymer.

Therefore the dependence of strength of SE on the strain rate becomes weaker (Fig.3).

This is a remarkable property of a material with diverse hard blocks.

Fig.3. The ratio true

tensile strength fp /minimal value of true tensile strength

fp min versus strain rate: 1 – without urethane blocks (õ1=1),

2 – with diverse hard blocks (õ1=0.5).

Therefore,

use of mix with aromatic diamine and low-molecular-mass diol for SE synthesis allows

to regulate physical-mechanic properties of urethane-containing elastomers in

wide limits.

An extreme

dependence of strength on the mix composition is a result of combination of two

factors: increasing in the interchain interaction in the soft phase due to the

dissolution of urethane hard segments in it, and the microphaase segregation of

hard and soft segments. The forming hard phase is a reinforcing filler. The

increase in the microphase segregation degree leads to the decrease in the

interchain interaction.

Experiments

carried out at different strain rates allowed to show a fundamental feature of

behavior of SE with mixed hard blocks. The

balanced influence of hard and soft phase on the physic-mechanical properties

of such materials allows to weakening of the influence of a material strength on

the strain rate. High values of strength of SE are achieved in a wide range of

strain rate.

The work was carried out with the financial

support of the program of Branch of Chemistry and Material Sciences of RAS «Creation

and investigation of macromolecules and macromolecule structures of a new

generation» (project 12-Ò-3-1005), and the

Russian Foundation for Basic Research with the Government of Perm kray (project

13-03-96000).

References

1. Prisacariu C. Polyurethane

Elastomers. From Morphology to Mechanical Aspects. NewYork: SpringerWien, 2011.

255p.

2. Randall D; Lee S. The polyurethanes book. New York: Wiley; 2003. 494p.

3. Tereshatov V.V., Tereshatova E.N., Makarova M.A.,

Tereshatov S.V. Influence of chemical structure and

composition of mixed soft segments on the properties of elastomers with

urethane-urea hard blocks // Polym. Sci. 2002. Vol. 44A, No 3. Ñ. 275-281.

4. Tereshatov V.V., Strel’nikov V.N., Makarova M.A.,

Senichev V.Yu., and Volkova E. R. Structure and Properties of Segmented

Polyurethane-Ureas with Dissimilar Soft Blocks // Russian J. of Appl. Chem.. 2010. Vol. 83, No. 8. P. 1380-1384.

5. Petrovic

Z.S. and Ferguson J. Polyurethane elastomers // J. Polym Sci. 1991.Vol. 16. P.695-836.

6. Vasiliy V. Tereshatov, Marina A. Makarova, Valeriy

Yu. Senichev & Alexey I. Slobodinyuk. Interrelationship between ultimate mechanical properties of variously

structured polyurethanes and poly(urethane urea)s and stretching rate thereof

// Colloid and Polym. Sci. 2012. V. 290, Issue 7. P. 641-651.

7. Yeh F., Hsiao B.S., Sauer B.B., Michel S., Siesler H.W.

In-situ studies of structure development during deformation of a segmented

poly(urethane-urea) elastomer // Macromolecules. 2003. Vol. 36, No 6. P.1940-1954.