THE BASIC DIRECTIONS OF IMPROVEMENT OF QUALITY THE UAV

EXTERNAL SURFACES

Prof. Nickolay

Zosimovych

Sharda University, Uttar

Pradesh, India

As a result of perfection of

forms modern and perspective UAV probes of typical geometrical parameters of a

surface have been made and the technique of appointment of admissions on

external surfaces is offered.

Key

words: Unmanned Aerial Vehicle (UAV), surface, aerodynamic quality, sinuosity,

technological roughness’s, ledge,

indent, constructive and technological actions, fuselage, fuel consumption, specifications,

flying vehicle (FV).

Introduction. Increase

of efficiency UAV is caused, on the one side, by a problem of fuel resources,

and with another side a tendency of change of structure of expenses for life

cycle aside reduction of a share of initial FV cost. Aircraft

engineering practice marks following basic ways of increase of FV efficiency [312]:

1. Application of

essentially new constructive decisions and materials (10…20%).

2.

Perfection of engines (20…30 %).

3.

Aerodynamics perfection (to 40 %).

The importance and urgency of improving the aerodynamic efficiency by improving the forms of modern and advanced FV, including by improving the quality of exterior surfaces, confirmed by the entire history of aviation.

Detailed

consideration of dependence of resistance from quality of performance of

external surfaces by manufacture shows that additional resistance can reach

2…10% at zero upward force [315]. The greatest share is brought by the

deviations increasing a lateral section, details for example acting in a stream

(approximately 5 %). Nearby 1.2 … 1.5 % are necessary on rivets and bolts

connections; 0.5 % on joints of sheets; leaky position of shutters and hatches gives

1.0…1.5 %; rough coloring (over 20 microns) – up to ![]()

At

speed from above М=1.5 the size of

all components increases approximately twice and resistance from a sinuosity -

more than in 5 times. For the reasons specified above the resistance increase

through technological roughness’s for subsonic FV makes approximately 5…6 %, and

for supersonic (М=2-3) - 10…16% [315].

Perfection

of quality of external surfaces probably at the expense of constructive and

technological actions that in turn can lead to additional expenses. Therefore

an important question at definition of quality of external surfaces is the

choice of criterion for quantitative estimations of similar actions. As such

criterion for a quantitative estimation of losses from additional resistance it

is possible to accept the expense or fuel cost. The expediency of an estimation

of such kind is obvious, as fuel consumption is unique precisely measured

parameter at the given design stage UAV, directly reflecting infringement of

aerodynamics of a surface, both in manufacture, and in operation [313].

Problem statement. In development of designs FV

and, accordingly, technologies of their manufacture always crucial importance

had constant increase in speeds of flight [312]. Growth of speeds of flight not

only causes of application of new, more and more heat-resistant materials (fig.

1), but also is accompanied still nearby important for development of the

production technology of tendencies [234].

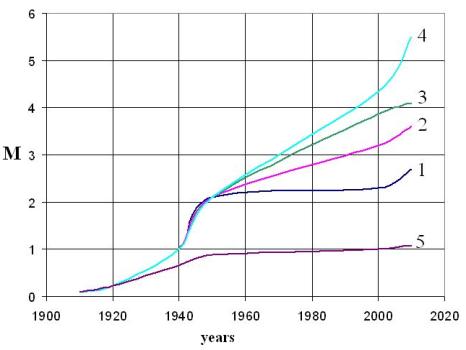

Рис.

1. Growing of speeds of flight of

FV: 1)

for aluminum designs; 2) for titanium designs; 3) for designs from special steels;

4) for designs from special alloys; 5) for subsonic UAV

It

first of all concerns change of forms of units FV [316, 317]. Simple

rectilinear forms of surfaces of units of a glider in process of growth of

speeds pass in complex surfaces of double curvature. To the production

technology the total disappearance of cylindrical formations of fuselages is

essential almost at speeds from above М=0.85 and linear

surfaces of wings and plumage, since the speeds from above М=2.0. On change by their surfaces characterized by

complex enough laws of formation of the form come [315].

The proceeding increase in speeds (at least to М=3,5…4,5) causes toughening of requirements to

accuracy of the external contours, interfaced to serious problems in the field

of technology and designing of units [317].

Deviation

of elements of a surface from a theoretical contour, a raising of heads of

bolts, rivets, screws in a stream, steps, a roughness etc. on everyone concrete

FV or group of planes are appointed in specifications developers.

Maximum

deviations on elements of aerodynamic surfaces are defined proceeding from

admissible sizes of additional resistance![]() and flow conditions on various modes. As a rule, specifications on the

form and quality of a surface of the airplane provide division of units into

zones according to their importance in formation of a streamline stream. Typical

requirements to parameters of quality of surfaces UAV are in a range of

and flow conditions on various modes. As a rule, specifications on the

form and quality of a surface of the airplane provide division of units into

zones according to their importance in formation of a streamline stream. Typical

requirements to parameters of quality of surfaces UAV are in a range of ![]() мм [312].

мм [312].

To the

first zone carry surfaces of units to which increased requirements on quality

of a flow are shown. Higher requirements are accepted for a wing ![]() мм, less high ones for

a fuselage at great numbers

мм, less high ones for

a fuselage at great numbers ![]() and thickness of an interface. Conditions of preservation of a laminar

flow are put in a basis of requirements at small numbers

and thickness of an interface. Conditions of preservation of a laminar

flow are put in a basis of requirements at small numbers ![]() as there is an opinion that roughness’s start to influence, if their

height exceeds a thickness of a laminar local layer [134].

as there is an opinion that roughness’s start to influence, if their

height exceeds a thickness of a laminar local layer [134].

Additional

resistance from a surface sinuosity is in sedate dependence on size of a

deviation of a surface and its position concerning a forward edge [35]. This

circumstance is considered in specifications at definition of zones of surfaces

of units.

Taking

into account similar reasons restrictions of size of local roughness’s of type

of ledges, ledges, cracks and fixture heads are generated ![]() мм [312].

мм [312].

Results of researches. By working out of

constructive and technological decisions it is necessary to define the

requirements shown to quality of object of manufacture and technological

processes, in particular to appoint maximum deviations of aerodynamic surfaces.

To

typical deviations of geometrical parameters of elements carry out next [312]:

1) smooth

deviations from the theoretical contour, measured by comparison of an actual

surface from the ideal. In practice as the ideal accept a surface set in one of

systems:

а) the measuring machine on the basis of mathematical model

of a surface;

б) reference surface in the form of its

breadboard model;

в) flat carriers of the form and the sizes at

use plaza and sample methods, means of spatial coordination, control templates

or assembly equipment;

2) eminence of one

part of a surface over another against a stream (so-called ‘step’) or on a stream

(‘ledge’). Geometrical parameters appreciate by results of excess measurements;

3) smoothness of

transition of one part of a surface in another (so-called ‘sinuosity’),

characterized in the length of a wave and amplitude. The sinuosity is

classified on character of display [321] - cylindrical or spatial. This kind of

an error of an external surface is defined by discrepancy of manufacturing and

design assemblage in which result there are the internal pressure covering all

sections or its parts. Local deformations occur owing to formation of

connections (rivets, welded seams). Sinuosity measure or concerning a base

line, a tangent to the maximum roughness (ruler), or by results of comparison

of an actual surface with ideal [312]. At a smooth deviation of contours on![]() sinuosity size on base

sinuosity size on base![]() makes

makes![]() where

where ![]() is scope of an error. At the set size of the admission

is scope of an error. At the set size of the admission![]() it is necessary to accept

it is necessary to accept ![]()

4) local excess of

elements of a surface in the form of acting (sinking down) heads of fixture. These

errors are registered by means of universal and special measuring instruments. The

basic geometrical parameters of deviations are the height ![]() and diameter

and diameter ![]() [321];

[321];

5) cracks through

or without an exit between elements of a surface of the unit. These errors also

are measured by universal tools or special templates and characterized by the

relation of width ![]() to depth

to depth ![]() т.е.

т.е. ![]() or the admission for width of a

through crack [321];

or the admission for width of a

through crack [321];

6) punching of an

external surface of the unit owing to defects of a surface. These errors are

limited by an equivalent aperture on area unit [312] (Fig. 1).

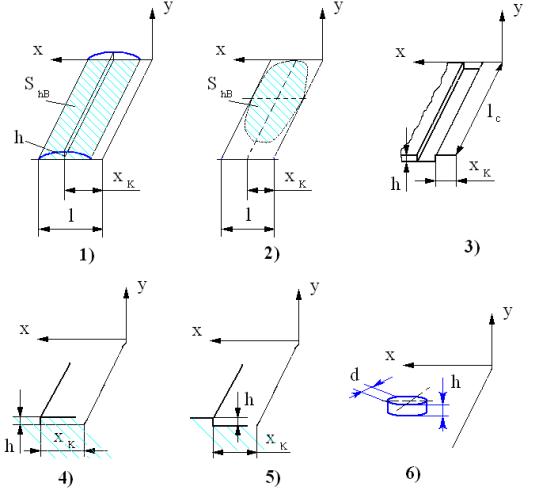

Fig. 1. The typical

geometrical parameters of a surface limited to admissions: 1) cylindrical

sinuosity; 2) spatial sinuosity; 3) crack (a backlash); 4) ledge against a stream;

5) ledge on a stream; 6) punching

Admissions

on a relative positioning of global surfaces of separate units and units among

themselves in this case are not considered.

Technique

of appointment of admissions on external contours of flying vehicles. For the purpose of definition of a generality of the constructive and

technological decisions accepted in specifications, revealing of the reasons

defining size of the admission have been analyzed specifications for more 30 FV

various types and appointment.

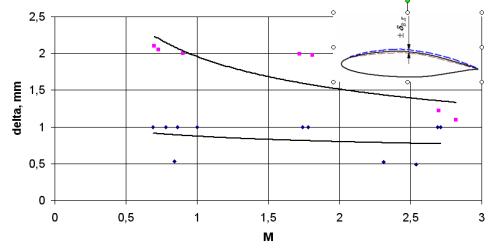

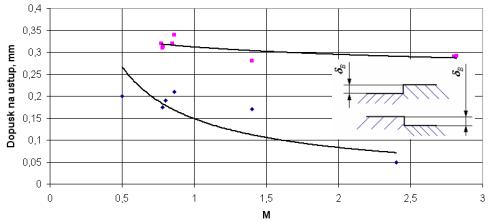

Fig. 2. Dependence

of change of the admission on a deviation from a contour of the unit from speed

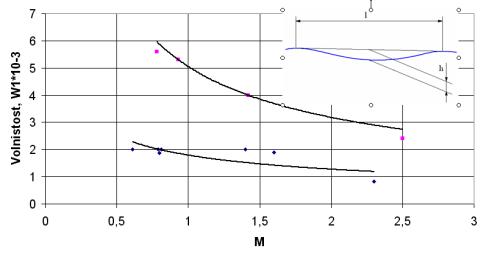

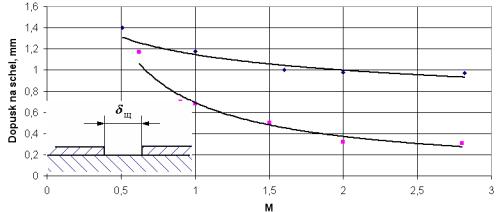

Fig. 3. Dependence

of change of the admission on parameters of a sinuosity of a surface from speed

Fig. 4. Dependence

of change of the admission on parameters of a ledge of a surface from speed

Fig. 5. Dependence

of change of the admission on parameters of a crack of a surface from speed

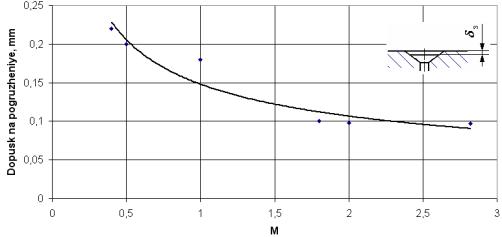

Fig. 6. Dependence

of change of the admission on immersing parameters in a surface from speed

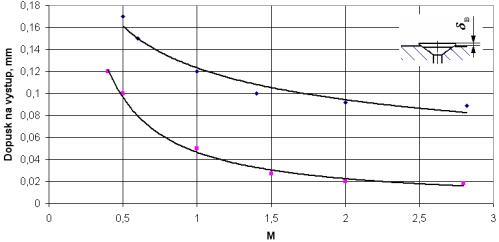

Fig. 7. Dependence

of change of the admission on parameters of a ledge from a surface in from

speed

On Fig.

2-7 the schedules constructed by results of statistical processing set in specifications

of admissions are presented.

Conclusion. The analysis of appointment of

admissions on external surfaces of units FV, practice of their appointment and

realization in manufacture allow to draw following conclusions:

1. Practically FV in

one interval of numbers![]() admissions on performance of geometrical elements of an external

surface are identical to all and decrease with growth

admissions on performance of geometrical elements of an external

surface are identical to all and decrease with growth ![]() Admissions for supersonic UAV

Admissions for supersonic UAV![]() approximately twice it is less, than admissions for the subsonic

ones. The general feature is the task of various requirements for a wing,

plumage, a fuselage, gondolas and flows. The highest requirements to quality of

an external surface are shown to a wing, as to the unit creating carrying force.

approximately twice it is less, than admissions for the subsonic

ones. The general feature is the task of various requirements for a wing,

plumage, a fuselage, gondolas and flows. The highest requirements to quality of

an external surface are shown to a wing, as to the unit creating carrying force.

2.

Necessity of decrease in weight and durability increase has caused

transition from a traditional modular design for power compartments to the

monolithic. Application of composite materials that has led to change of

conditions of realization of the admissions set on external contours extends. In

due to manufacture automation methods of the task and means of reproduction of

surfaces forming contour UAV will change. In these

circumstances of a condition of realization of admissions it is necessary to consider in two aspects: in design, i.e. according to the possibilities of formation of the set accuracy of contours put in a design, and in industrial and technological, i.e. according to possibilities of existing and perspective technological processes and the equipment providing set accuracy.

3. Experimental researches

of the isolated roughness are put in a basis of calculation of resistance from roughness’s

taking into account its site in the boundary layer. The roughness height is

defined by admissible size of additional resistance ![]() . Practical technique to an establishment of dependences and functional

communications between values of admissions and expenses by the generalized

criterion and consequently, and to a choice of economically optimum admissions,

still it is not defined unequivocally. Therefore for the generalized criterion

accept additional fuel consumption because of resistance of roughnesses, as

influence of additional resistance on speed almost slightly.

. Practical technique to an establishment of dependences and functional

communications between values of admissions and expenses by the generalized

criterion and consequently, and to a choice of economically optimum admissions,

still it is not defined unequivocally. Therefore for the generalized criterion

accept additional fuel consumption because of resistance of roughnesses, as

influence of additional resistance on speed almost slightly.

References

1.

Негреба В.А., Фирсов В.А., Бобрыкин Ю.А. Технологические основы

проектирования конструкций самолетов. – М.: МАИ, 1986. – 43 с.

2.

Краснов Н.Ф., Захарченко В.Ф., Кошевой В.Н. Основы аэродинамического

расчета. Трение и теплопередача. Управление обтеканием летательных аппаратов /

Под ред. Проф. Н.Ф. Краснова: Учебное пособие для студентов втузов. – М.: Высш.

шк., 1984. – 264 с.

3.

Мероприятия зарубежных авиакомпаний по экономии топлива. – Техническая

информация ЦВГИ, 1981, № 9, с. 30-32.

4.

Горобець С.М. Основи

комп’ютерної графіки: Навч. пос. / За ред.. М.В. Лемківського. – К.: Центр

навчальної літератури, 2006. – 232.

5.

Вигдорчик С.А. Технологические основы проектирования и конструирования

самолетов. Часть 1. – М.: МАИ, 1974. – 140 с.

6.

Проблемы строительной механики и прочности ЛА: Тем. сборник науч. тр. /

МАИ. – М.: МАИ, 1990. – 72 с.

7.

Зосимович

М.В., Шелудченко Б.А., Войцицький А.П. Еколого-економічне обґрунтування проекту утилізації радіоактивних

відходів в далекий космос при міжнародній співпраці // Вісник

Сумського державного аграрного університету. - 2001. -

Т. 1 - Суми: вид-во “Козацький вал”.-

С. 75-80.

8.

Прочность,

устойчивость, колебания: Справочник в 3-х т. / Под ред. И.А. Биргера и Я.Г. Пановко. – М.:

Машиностроение, 1968. – Т. 3.

9.

Фирсов В.А. Воспроизведение

обводов самолета в системе автоматизированного проектирования. – М.: МАИ, 1978.

– 72 с.