Doctor of Science Medvedev A.,

postgraduate student Maltseva T.

Siberian State Aerospace

University named after Academician M. F. Reshetnev

On a new

approach to the identification of complex processes

Introduction. It is expedient to use all

measurable variables while of multidimensional discrete-continuous processes

modeling and control but it requires a detailed analysis of not only the

process itself, but also the control tools and techniques of all the available

variables, as well as a priori information that can correspond to different

levels [3]. The omission of variables, nature and the discreteness of

measurement and control of different types of a priori information, as well as

some «liberty» in making certain assumptions that are inevitable when a mathematical

formulation of the problem can lead finally to negative consequences. All these

questions due to a large number of variables and the high complexity of the

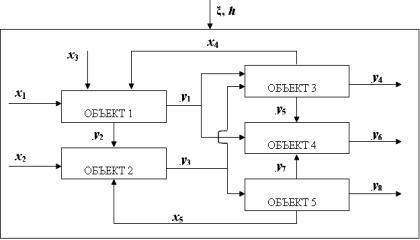

internal connections of the studied processes (Fig. 1) are often omitted in the

modeling problems investigation from a theoretical point of view.

![]()

![]()

Fig. 1.

General scheme of the multidimensional multiply process

It is

simply impossible when solving the same applied problems when the investigated

process is for sure multidimensional and multiply connected. In this paper we

will present models of this type processes.

Nonparametric combined models. Often while

studying the real process we are facing the situation when information about

the form of some of its correlations is missed that leads to the greater

complexity in obtaining their parametric models. However, some correlations

technical, technological features, can be described parametrically or even can

follow the known laws of physical, chemical, electrical, mechanical and other phenomena.

Thus, different communication process can be studied in different degrees, i.e.

a priori information can belong to different levels. As a consequence, the

various mathematical problem statement from the mathematical point of view in

the framework of one of the modeling problem of the interested process.

The

objective necessity to get models of the similar processes, a lack of a priori

information, the random factors influence, with unknown characteristics,

discrepancy by sampling for measuring,

and a lack and imperfection of measuring complexes leads to assumptions and

hypotheses about the investigated process that often have little connection to

the reality. The “ignorance” about the structure must be unfortunately

replaced, saying, «Let the process be described by the equation of the

following form...» and the restriction of the control means by «Let such

factors are not changed /do not influence the process…» and so on. If our

assumptions are close enough to the reality, so we can rely on success in the

problem solving (indeed, a large number of the processes based on fundamental

laws and can be described with a high degree of accuracy), and if the

assumptions are too rough, it seems, there exist two methods. The first one is

to fill our «ignorance» about the process, when it will be possible to make an

accurate problem from a mathematical point of view. The second one is

development of the mathematical approach adequate to the level of a priori

information we have. In this paper, we will follow the second method.

Mathematical models of processes built in conditions, when a priori information

about the investigated process may simultaneously belong to several levels, and

be based on the three pillars: fundamental laws, parameterized dependencies and

connections reflecting only the dependence nature of some process variables

from others and will be called Ê-models[3].

Let’s

take an example of Ê- models building

of some technological process which complexity is represented not only in the

large dimension of the vector variables, but in the presence of backward and

cross flows in technological complex (Fig. 2). This may be the company united

in industrial complexes, and a set of different production  stages, trade and

bank networks, and others.

stages, trade and

bank networks, and others.

xi, i = 1,…,5 – input and reduced variables;

xi, i = 1,…,5 – input and reduced variables;

OBJECT 3 OBJECT 1

yi,

i = 1,…,8 – input

variables;

OBJECT 5 OBJECT 4 OBJECT 2

ξ, h – random noise with zero mathematical

expectation and bounded variance influencing objects and measurement channels

Ðèñ. 2.

Conditional block diagram of the multiply connected object

As we

can see in Fig. 2, feedbacks lead to the fact that some of the vector

components of the output depends on other its components, and the investigated

class of objects is described not in the traditional form of «input - operator

- out», but in the form of equations system that determines the appropriate

implicit functions. The complex nature of internal correlations leads us to the concept of compound vectors, i.e.

vectors composed of some components of the corresponding vectors of input and

output variables [3]. For example, for an object 1 in Fig. 2 compound vectors

are ![]() and

and ![]() .

.

Let's

formulate the problem. Let for a multidimensional static object influenced by

uncontrolled disturbances with random errors having zero mathematical

expectation and limited dispersion, the following observations {X[t], Y[t]}, t=1,2,...,N of the state

vector {X, Y} may be conducted. The

probability density p(X), p(Y)

are unknown. It is known that the variables {X,

Y} on the object are connected by some relations, some of which are known

exactly (on the basis of the fundamental laws)

![]() ,others are known with accuracy to the parameter set

,others are known with accuracy to the parameter set

![]() , and some ones due to the lack of a priori

information about the structure cannot be parameterized and presented as

high-quality ratios of input - output.

, and some ones due to the lack of a priori

information about the structure cannot be parameterized and presented as

high-quality ratios of input - output.

Then,

having an observation sample {X[t],

Y[t]}, t=1,2,...,N, we need to find such a value of the output![]() , corresponding to a given input impact -

, corresponding to a given input impact -![]() that is, to make the forecast of the system output

according to a given input impact.

that is, to make the forecast of the system output

according to a given input impact.

Let’s

present a model of the system in the form [3]

(1)

(1)

where

(2)

(2)

- nonparametric

estimation of quality dependencies according to the observations of the state

vector of the object; ![]() - an equations

found on the basis of the known fundamental laws;

- an equations

found on the basis of the known fundamental laws; ![]() - parameterized components of the corresponding vector

functions; X(j), Y(j) -vectors

composed of various components of the corresponding vectors of input and output

variables used in the description of the preferred correlations [2], Φ(.)

- bell-shaped function, parameters of fuzziness C satisfies conditions of

convergence [3].

- parameterized components of the corresponding vector

functions; X(j), Y(j) -vectors

composed of various components of the corresponding vectors of input and output

variables used in the description of the preferred correlations [2], Φ(.)

- bell-shaped function, parameters of fuzziness C satisfies conditions of

convergence [3].

Undoubtedly,

the offered Ê-models have a complex enough form (1), but reflect

more accurately properties of the run process in this or that object. They are

fundamentally different from the well-known models that combine equations,

obtained on the basis of the fundamental laws, technical, constructive

peculiarities of the process and its parametric and non-parametric components

as a whole.

The

model simplification of the discrete-continuous process will inevitably lead to

a deterioration of its quality, and it is possible that the simplified model,

in contrast to the models of the type (1), are not suitable for the production

of high-quality forecast systems of automatic control because of its roughness.

Note that we do not belittle the value of the classical models: they work well in

situations in which it is foreseen to their applicability. The application

of Ê-models are not available for

the of the many processes description, say, for mechanical or electrical ones, such as electrical machinery,

turbines, reactors and generators as they are controlled well enough and required

classical models. In reality, however, we have to face situations when it is

unable to receive such models for control required for the adequate

application. We want to emphasize that, in fact, a Ê-model is not uncommon and it

is not fiction, they are applied in a wide variety of natural, technological,

and social and economic processes, and that the application of the model of

such a complex form is justified. As an example we consider the process of oil

geofiltaring in a porous medium because of a spill from a pipeline.

Ê-models

the oil pollution process of the porous medium. The human activity associated

with the oil use as a primary source of energy, led to the pollution of the

environment. The most serious soil pollution by petroleum products arises from

various emergency situations. Withheld porous media hydrocarbons represent a

serious problem for the environment due to their toxicity and the potential to

serve as a long-current source of pollution. In this regard, the investigation

of the filtration processes in the models of porous media, the most adequate to

the natural conditions, is a topical issue, which will allow receiving the

forecast of forming the front of pollution and estimate the polluted zone.

The

monitoring process is of considerable complexity, because at oil pollution

interact three groups of factors to consider in assessing the effects of soil

pollution with oil and oil products: multicomponent composition of oil; the

heterogeneity of the composition and structure of soil ecosystems; the

diversity and variability of the external factors [5]. Moreover a significant

role in the formulation of modeling problems belongs to the control tools and

technology of variables control; and the investigated geofiltaring process is

unavailable to the direct investigated field (oil pollution). These

difficulties lead to the fact that at the stage of problem formulation an

investigator has to use the assumptions having little relation to reality.

Mathematical modeling is always accompanied by some assumptions that are useful

from the practical point of view in making the problem solvable. The adopted

assumptions in the general may be too «rough» and lead to the fact that the

model will be inadequate the reality. The present paper presents an attempt to

formulate the task of the modeling production process releasing some

assumptions due to the lack of a priori information. It is offered to use a new

type of mathematical models Ê-models for this purpose:

Fig. 3. Scheme of the process

geofiltaring in a porous medium

The

input variables (analogues of X in

the previously proposed problem formulation) are defined by the parameters of

three interacting systems: soil (Q1),

oil (Q2) and environment (Q3); at the output, the model

produces the spatial oil (parameters Π and L,

defining parameters of three-dimensional cylindrical surface) and the pollution

level (α) (analogues of Y).

Variables Π and L are different output variables, because they are determined by

different physical processes, and have different measurement discreetness (a

size of the spill is controlled quite often by the aerial, a depth of

penetration is measured once by carrying out prospecting ensures after the fire

season, during which the actively in the process of evaporation of light oil

fractions from the soil surface). ξ(t) – vector random effects. ![]() - variables of the process (saturation, filtration

rate, depth of oil pollution), determined by the model based on the equation of

continuity and Darcy’s law [5] and the

additional information about the process; H

– communication channels corresponding to different variables, which include

control measurement tools of the observed variables; Q1t, Q2t, Q3t, Dt, Ït, Lt, αt - measurement of

the corresponding variables in discrete time t; h(t) is random noise variables

measurements of the process.

- variables of the process (saturation, filtration

rate, depth of oil pollution), determined by the model based on the equation of

continuity and Darcy’s law [5] and the

additional information about the process; H

– communication channels corresponding to different variables, which include

control measurement tools of the observed variables; Q1t, Q2t, Q3t, Dt, Ït, Lt, αt - measurement of

the corresponding variables in discrete time t; h(t) is random noise variables

measurements of the process.

We also note the significant difference of output variables Π(t), L(t)

and α(t). The output variable Π(t) is controlled by time intervals Δt, for example, on

the basis of aerial data; L(t) – through significantly large time

intervals ΔT (by drilling holes by the accepted technology),) α(t) - through T (T

> ΔT>> Δt) (with the help of chemical analysis of soil samples

by the obtained pitting [1]). The variables control α(t) for the

investigated process is often the most important from the practical point of view [1]. Despite the

fact that the process of geofiltaring is dynamic, the existing control tools were forced to consider as a

static delay, however the choice of this models class does not contradict the

modeling objectives because the simulation result has practical value at the

time when the transition process is over and passed in the established mode.

Thus,

the geofiltaring model suggested to be built on the basis of physical laws,

equations of the two-phase filtration theory [5] (fundamental dependencies),

methodologies of the main parameters calculation applied by services of

ecological safety [1], and the information about the phenomenon under

consideration obtained in earlier studies [5] (parameterized dependencies) but

also the qualitative information that can currently be presented parametrically

due to the lack of information about

the form of the relationship (non-parameterized dependencies), that leads to Ê-models.

Conclusion. The paper presents a new type

of models of a complex stochastic process, combining the equations obtained on

the basis of the fundamental laws, technical, constructive peculiarities of the

process and its parametric, and non-parametric components as a unit. The

presented models are fundamentally different from those ones used in

identification. The simulation problem formulation is carried out in conditions close to real conditions of the

similar processes, depending on the available a priori information. For

example, the process of oil geofilaring in a porous medium shows the real

necessity for the proposed models application for the complex processes

description, as proposed models make it possible to depart from a number of

assumptions on the stage of problems formulation and to get the forecasted

values of the interested process

variables in the information situation, which is really observed for such a process.

References

1. Zagvozdkin V. K., Zaikin

I. A., Bikov A. A., Makiev

U. D., Makishev D. V., Nazarov

V. B. Metodika

ocenki jekologo-jekonomicheskih posledstvij zagrjaznenija zemel' neft'ju i

nefteproduktami // Problemy analiza riska.– Moscow, 2005. – Vol. 1(2), pp.

6–28.

2. Maltseva

T. V., Medvedev A. V. O komp'juternom issledovanii K-modelej // Krasnoyarsk,

2013. – Vol. 3 (49).

3. Medvedev

A. V. Teorija neparametricheskih sistem. Modelirovanie

//Krasnoyarsk,

2010. – Vol. 4., pp. 4–9.

4.

Medvedev A. V. Computer Modeling of Active Processes // Modern Scientific

Research and Their Practical Application. – Ukraine, 2013. – Vol. J11307.

5.

Molokova N. V., Konnykh M. A. Modeling of the Dynamics of Spreading of Spilled

Hydrocarbons Taking into Account the Gravity-Capillary Interaction // Krasnoyarsk:

SFU, 2012. – Vol. 5(4), pp. 462–470.