UDK

631.18.004.82

A.A.Aulanbergenov

Kazakh

National Agrarian University, Almaty

Issues

of water supply and water drainage on private farm in Kazakhstan

Water supply and water drainage on private farm with livestock population up

to 100 heads of cattle needs establishing

production without wastes, on utilization of organic wastes and

livestock drains. The conducted

experimental researches on identification of the norms of water supply of the

cattle in Almaty region have shown that daily water consumption is qpac ==33

34

l/day, coefficients of hour and daily

unevenness are αr=2,13,

αday=1,07.

On water drainage norms we have obtained the following data:

Water

drainage for the cattle for cattle is

44

45 l/day, formation of hard drainage (moisture 73

76%)-6,9..72m3/day. Coefficients of hour and daily unevenness

are: λx=1,98 λday=1,2 λgen=2,3. The regime and

norms of water consumption of cattle have been studied, structural analysis of

sediment have been done and physical and chemical features of livestock drain

have been identified.

Chemical analyses of cattle drain have

showed the following: chloride content 3,3

5,2 mg/l, iron is missing;

magnium-421

546 mg/l; quantity of calcium has fluctuated in wide range; ammonia

nitrogen - 32,0

40,0 mg/m; BPC5 3200

4300 mg/l; BPCcomplete 4600

5660

mg/l; CPC-14700

15600 mg/l; weighed substances 17,9

18,7 g/l; common nitrogen-

1,3

1,4 g/l and hydrogen index PH-

8,06

8,07.

On bacterial analysis of cattle drain

we have obtained following data: colony calculation- 1,2

2,01-106 mln.; index number-more than 10 billiards;

pathogenic flora is missing. General analysis shows that indices of VPC, HPC,

phosphorus and potassium are slightly high. Before using such drain for

irrigation it is necessary to make the required norm of concentration of

elements of content of the drain by

means of processing using method of anaerobial fermentation on special devices.

Processed drain meets environmental

requirements, eliminates infection of people and animals with disease agents,

soil, ground water and plants

overloading with harmful substances and microorganisms. Simultaneously

we can obtain low cost fuel such as biogas consisting of methane (65

70%),

carbonic acid gas (27

32%) and hydrogen sulphide (up to 3%). Energy contained

in 30 m3 of biogas is equal to the energy of 18 m3 of

natural gas, 22 liters of oil, 20 liters of diesel.

World energy and environmental crisis

of 70th of XX century has preconditioned wide development of biogas

technology in USA, Germany, England, France, Italy, Finland, China, India and

other countries. At present period in China there are more than 5 millions and in India more than million of biogas

devices with reactor volume of 8-10 m3, that provide more than 50

min. farmers with gaseous fuel .

In the US biogas covers

1,6% of energy consumption in agriculture and in India it covers more than 20%.

In general the development and implementation of small capacity biogas device

on farms in the republic will provide solution of energetic and economic

problems in rural places.

Therefore in choosing and development

of technological scheme of complex biogas system it is necessary:

-

to chop manure and other organic wastes to the

size of not more than 0,005 m and maintain content of moisture in the initial

substance on the level 88-90%;

-

during device launching the filling should be done within 5

30% of

the whole loading volume. Fermentation process should be thermophil (50-550).

It includes two phases. In the first phase up to 350C the process

takes place quickly, then in the second phase after 4-6 days temperature is

increased up to working temperature to

10C per day;

-

daily loading dose of working chamber of

bioreactor (methantenka) during heating period from 35 to 500 C

should be accepted as 10% and in the set regime-18-30% from loading volume.

Mixing of fermented substance should be done with the help of vacuum tower

every 5-6 hours 3-4 times;

-

for improving fermentation process of liquid

drain, 0,1% of carbon oxide should be added;

-

systematic control the quantity of pathogenic

microorganisms and viable helmint eggs in manure after fermentation.

Based on the requirements of the

proposed technological process of fermentation

of farm drain we have developed various schemes of bio energy devices.

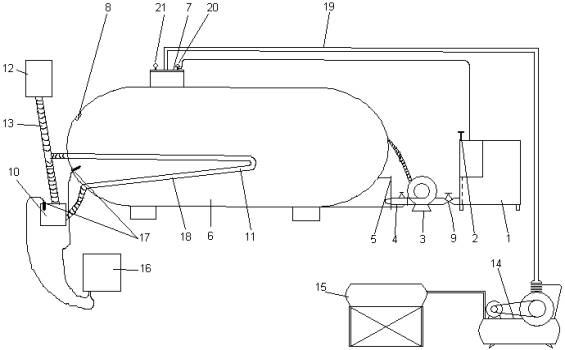

Construction of experimental bio energy device is shown on picture.

Liquid organic wastes and

manure drains on farm are taken to the

reservoir of 1 preparation of fermented manure and are kept there until needed

consistency, catalyser of sediment

fermentation process is added. Reservoir of preparation is covered with

damper 2 providing cycle loading of device with fermented material. Delivery of

prepared manure drains is done with the help of re-circulation pump 3, equipped

with homogenisator made as hydro monitor cone nozzles and is located on

loading-overflow hatch 5, with consideration of the most effective use of

stream energy. Bioreactor (methane

device) 6 is situated horizontally with

bottom decline 0,01-0,020 to

the loading-overflow hatch.

To conduct

montage, maintenance and repair-exploitation works the bioreactor is equipped

with technologic hatch with diameter 0,6 m situated in its upper part. Filling

level of bioreactor with drains and process of

their barbotage are controlled

with the help of vision window 8 situated up the calculation loading level. For

providing continuous fermentation

process in loading-overflow hatch the bolt

9 works for draining of the

changing quantity of thrown sediment.

To maintain optimal temperature for viability of mizophyl methane

bacteria in bio-reactor the system of electric heating is used that consists of

electrode water heater 10 type EVM, tubular heat exchanger 11

situated inside bio-reactor, extending tank 12 and pipe line armature

13. For throwing output biogas (methane) the system of pumping out and storage

is foreseen including piston compressor

14 and receiver 15 with 1 m3 volume.

Research results show that the

assumed bioenergy device provides automation of technological process of bio gas production and obtaining of

qualitative organic fertilizer.

Pic. Principal scheme of

experimental bio energy device.

1-reservoir of

drain preparation; 2- damper; 3-

re-circulation pump; 4-hydromonitor device; 5- loading-overflow hatch;

6-bio-reactor; 7- technological hatch; 8- vision window; 9- bolt; 10 electrode

heater; 11- tubular heat exchange; 12- extending tank; 13- pipe line armature; 14- compressor; 15-

receiver; 16-mangement box; 17- TSM sensors.

Publications:

1. A.Sasson. Biotechnology. M.: Mir,-1982

2. V. Baader and others. Biogas (theory and practice). M., Kolos,-1982