Ecology/2. Ecological and meteorological problems of cities and

industrial zones.

Cand.tech.sc. Stolyarova N. A., Chekhlan N. À., Egorova Å. À.

Automobile-Highway Institute of the State Higher Educational

Establishment «DonNTU», Ukraine

Utilization of fluorescent lamps on

the demercurization equipment «Ecotrom-2»

Problems relating to the

environmental pollution by mercury and its compounds rank high among actual

ecological issues. Mercury

is one of the most dangerous metals polluting environment. Wastes containing

mercury are referred to the first (the most dangerous) danger class. Energy efficient fluorescent lamps

are especially dangerous from the position of the local pollution by toxic

mercury. The most widespread types of fluorescent lamps contain mercury up to

300 mg.

The mercury extraction process from lamps is executed by

the demercurization on special equipment. Demercurization is the process of

mercury and its compounds extraction by the mechanical or physicochemical

methods. Its purpose is the avoidance of

man’s intoxication by mercury vapour [1].

The problem of the mercury pollution prevention

is decided in many respects by the efficiency of techniques applying for the

neutralization and processing of wastes containing mercury.

The method of the fluorescent lamps processing

was developed and introduced by the scientific production association «Ecotrom»

(Russia) on the basis of which modifications of the installation «Ecotrom-2» were developed. They allow to process mercury-containing

lamps of different shapes and sizes.

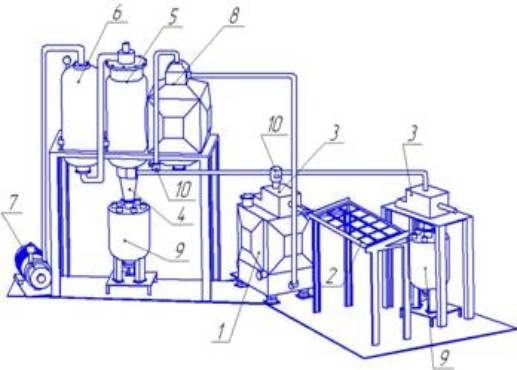

Operating principal of the pneumatic vibration

installation «Ecotrom-2» (Fig.1) is based on the separation of

fluorescent lamps into main components: glass, metallic lamp cap and

mercury-containing luminophor.

The installation is composed of two main

blocks: lamp separation unit containing loading unit, pneumatic vibration

separator with a crusher, cyclone and purification system involving bag filter,

absorber and gas blower with compressor.

Fig.1 – Installation diagram «Ecotrom-2»:

1 – pneumatic

vibration separator, 2 – loading unit, 3 – pneumatic impact crusher, 4 – cyclone, 5 – fine filter,

6 – absorber,

7 – gas blower,

8 – intermediate collector of crushed glass,

9 – transport

technological collector of luminophor ,

10 – stopcock.

The processing of fluorescent

lamps on the installation «Ecotrom-2» is carried out as follows: fluorescent

lamps delivered in the special containers are fed in the loading unit. Due to

the high depression lamps are continually fed to the accelerating tube, get in

the crusher and crushed to a particle size of glass up to 8 mm [2].

Lamp caps are separated

from glass on the vibrating grid and removed in the collector – technological

container. As a result of heat treatment lamp caps are completely cleaned from

the residual mercury wastes.

The separation of the luminophor–the main mercury carrying agent,

from glass is carried out by its blowing in the countercurrent moving system «cullet-air»

in vibration. Glass purified from the luminophor

goes into the storage hopper.

The high efficiency of the installation «Ecotrom-2» should be

noted. The main characteristics of the installation

«Ecotrom-2» are given in the table

1 and in the table 2.

Table1 – Installation efficiency

|

¹ |

Name |

Number,weight |

Efficiency(per hour) |

|

1 |

Used lamps |

pcs. |

1200 |

|

2 |

Cullet |

kg |

250-280 |

|

3 |

Luminophor |

kg |

15-18 |

|

4 |

Lamp caps |

kg |

5 |

Table

2 – Installation power and material

consumption

|

¹ |

Number |

Number |

Unit |

Number |

|

1 |

Electric power |

including: |

kW/h |

11,0 |

|

2 |

Activated carbon |

absorbers |

t/year |

0,5 |

|

3 |

Compressed air |

bag filter air washing |

m3/year |

0,3 |

|

4 |

Sanitization |

sanitization |

l/shift |

20 |

Fluorescent lamps processing gives:

- glass –the major part of the lamp weight – it can be

recycled for the fluorescent lamps

production;

- metals –iron,

aluminium, copper – from contacts and ballast;

- glue and plastics – are not utilized currently. They

undergo recuperation during combustion;

- luminophor –is not recycled usually. After

the purification from mercury, it must be buried;

- mercury – is recycled. Recycled mercury covers up to

40% world requirements.

Literature:

1. Òèìîøèí Â. Í., Òèíÿêîâ Ê. Ì., Ìàêàð÷åíêî Ã. Â., Êî÷óðîâ À. Â. Äåìåðêóðèçàöèîííîå

îáîðóäîâàíèå «Ýêîòðîì-2» // Òâåðäûå áûòîâûå îòõîäû. – 2011. – ¹ 4