RESEARCH AND ORGANIZATION OF DIRECTED air flow in

centrifugal mixer

Borodulin D.M. 1, Sukhorukov D.V. 2

1

Kemerovo Institute of Food Science and Technology

2

Kemerovo Institute of Food Science and Technology

Russian Federation

The organization of the mixing process at the

present time is one of the priorities

of the decision which will significantly improve the quality of the

product and, thus, greatly reduce

the cost of its production. In the centrifugal mixers

organization forward and backward

movement brings the material flow structure of the movement

blend components to the model of ideal mixing.

In some designs of centrifugal mixer this method is

realized by direct particles

flows through the

bypass holes and windows formed on the conical surface

of the rotor and in the opposite direction through the

installation of various apparatus

in the form of

reflectors. They can be designed

as separate elements of the torus,

of identical size and installed in a staggered on different cones of the

edges smaller bases in the form of solid rings

and the rings with the holes

[1]. Common disadvantage of centrifugal continuous mixers (CCM) is that the

centrifugal force component in a highly

dispersed rise up. The result is

a partial bundle (segregation).

Currently, the leading scientists in the

field of mixing actually studied the effect of air currents on the quality of the mix,

but the more highly dispersed components that go into the airspace above the rotor mixer. Therefore, investigation of the direction and speed of air flow in the interior of the centrifugal continuous mixer is an actual

scientific problem of interest to many industries.

In operation, centrifugal mixers highspeed rotor by

centrifugal force, an air flow in

the movement of fine particles which are

involved components. The

resulting air currents affect the

structure of the material flow, moving

along the surface of the cones. This is reflected in the work of the entire apparatus. Thus, there is

a need to determine the nature and parameters of the air flow formed in the workspace mixer for further organization

of their direction of movement.

By rotating the cone of the rotor boundary layer of

air starts to move , due to friction . This layer moves away from the rotor

center to the periphery under the action of inertia forces . Air velocity can

be decomposed into three components : a peripheral Wp - tangential to the

surface of the rotor in the direction of its rotation , radial Wr - directed

from the center to the periphery of the rotor and an axial Wa - acting in the

vertical direction from the base of the rotor up. Thin radial movement of air

flow occurs in the vicinity of work surfaces mixer , such as a rotor housing

cover . Left airspace bounded work surfaces CCM rotates together with the rotor

with a slightly lower speed . Axial movement of the air flow occurs in the

direction perpendicular to the base of the rotor.

Constituent airflow will depend largely on the size of

CCM , rotor structure and its frequency of rotation. In our experimental

studies to determine the values of the velocity of

airflow was used centrifugal mixer [ 2], the rotor is made in

such a way that it could install different versions of the cone ( Fig. 1).

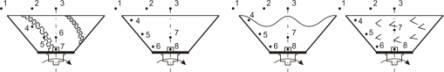

a b c d

a) smooth

cone with blades;

b) smooth

cone;

c) a

smooth cone with a wavy top edge;

d) a

smooth cone with angled vortex generators.

Fig. 1 Modifications of

cones

During the experimental studies, we used the following procedure.

The components of the air velocity was measured

at idle at various points and destinations within the rotor mixer. Measurements of air

velocity was carried out by a

microprocessor hot-wire anemometer-thermometer TTM-2.

For experimental studies on the rotor of a centrifugal

mixer alternately installed one of the versions

of the cones (Fig. 1). The measurements were performed at frequencies of rotation of the rotor 10 s-1 and

24 s-1.

From these results we can make the

following conclusions.

The axial velocity component. As the rotor

rotates with a frequency of 10

s-1 achieved its maximum value on a smooth cone with angled

vortex generators. It is more than 20%, 2% and 10%,

respectively, relative to Wa measured on modifications (a), (b) and (c). As

the rotor rotates with a frequency of 24 s-1 achieved its maximum value Wa achieved using modifications of the cone (d). Its speed is more than 12%, 8% and 7% with

respect to Wa measured on modifications (a), (b) and (c).

The radial component of velocity.As

the rotor rotates with a frequency of 10 s-1 to

smooth the air flow from the angled turbulators cone over 3% , 1 % and 17 % ,

measured by than Wr modifications (a), (b) and (c) . As the rotor rotates at 24

s-1 Wr reaches a maximum value on a smooth cone with angled vortex

generators . It is more than 20 %, 13 % and 16 % with respect to air flow

velocity in the radial direction of the cone modifications (a ), (b ) and (c )

respectively.

The circumferential velocity component in the range 1

.. 0.4 m/s is observed partial involvement of fine components in the air space

of the working chamber of the centrifugal mixer. Further increase Wp to 3.5 m/s

results in a swirling flow motion dusty and hence to the appearance of the

resulting mixture segregation process . This results in reduced efficiency of

mixing. The strong pattern is observed on a modification of the rotor in the

form of a smooth cone with throughputs windows and blades. Since the latter

provide additional ventilation effect, which leads to additional turbulence in

dusty threads, so to eliminate segregation and increase the efficiency of

mixing , an apparatus inside the mixer guide or reflective elements allow you

to specify the desired direction of air flow.

According to the results of experimental studies have

made the following conclusions.

We determined direction and velocity of air flow at

various points in the processing chamber of a centrifugal mixer with different

speeds and designs cone. When the values of

the circumferential velocity component in the range 0,4 ÷ 1 m/s, there

is a partial engagement of fine components in the air space over the working

chamber . Further increasing it to 3.5 m/s leads to a tangential movement dusty

flows (with particle diameters of 80 ÷ 120 mm) above the rotor and the

occurrence of CCM segregation process, which reduces the efficiency of mixing.

The strong pattern is observed on a modification of the rotor in the form of a

cone with an angled vortex generators that create additional ventilation effect

that enhances the speed of dusty flows. Therefore, its elimination and

increased mixing efficiency is advisable to install rails or reflective

elements, the direction of fine components contributing to the base rotor.

The experimental results showed that the lowest values

of the velocity of air flow falls on the center of the rotor. It was

established experimentally that in the center of the rotor is formed stagnant

zone. To eliminate it, we asked: do the base of the rotor in the form of a disk

with concentric hollow cone mounted facing up top, set over a cone axial fan

[3] or a reflector with a toroidal surface [4]. These designs allow you to

organize the directed movement of highly dispersed dust particle flows of

material in the chamber new faucets and increase the quality of the resulting

mixture at 2,5 ÷ 4,3%.

List of literature used

1. Borodulin

D.M. The development of centrifugal mixing equipment for dry and wet combined products: monograph / D.M. Borodulin, V.N.

Ivanec. - Kemerovo, 2012. - 178 p.

2. RF

Patent RU 104867, Russia IPC V01F 5/22, 2011.

3. RF

Patent RU 2216394, Russia V01F IPC 7/26, 2003.

4. RF

Patent RU 2200055, Russia V01F IPC 7/26, 2003.