Agriculture 4. Technologies of storage and processing

of agricultural products

Assoc. Prof. V.Yu. Ovsyannikov, graduate student Ya.I. Kondrateva,

student T.S. Kirichenko, student Yu.S. Kraminova

Voronezh State University of Engineering Technologies,

Russia

Estimation of loss of target

components in the refrigerant

concentration of cherry juice

In

order to investigate the influence of various factors on the concentration of

cherry juice freeze experimental setup used on the basis of the ice maker «Blexmatic

V41 electronic» with controlled heat

exchange area of freezing elements.

The

installation consists of a refrigeration unit with a system of supplying and

discharging the refrigerant, ensures the desired boiling temperature of the

refrigerant in the evaporator grunions, tilting bath container for the product.

Surface moisture freezing evaporator is a stud with ribs immersed in a bath of

the product.

The

weight of frozen ice determined in one cycle of the plant.

Power

refrigeration units allow the experiments to obtain the boiling point of the

refrigerant from 262 to 250 K by varying the cooling capacity of the

compressor. The pressure in the suction and pressure line of the compressor

controlled by means of pressure gauge placed on the dashboard.

In the

experiment recorded readings boiling point refrigerant in the evaporator, the

suction pressure and the compressor discharge flow rate of the product and the

cycle of freezing moisture.

After

the expiration of the freeze cycle adopted is 60 minutes pump motor switched

off, poured the remains of the product from the storage container into the

bath, the bath led to "turned" and the switching operation of the

refrigeration unit in the mode of "thaw." At the same time due to

switching solenoid valves, you can supply the hot refrigerant vapor in the

journal evaporator ice layer in contact with them and a fin element partially

melts the ice and slides freely with them in the ice storage.

After

freezing cycle is determined by the performance of the installation, frozen

ice, solids content of the concentrated product, and the solution obtained

after the melting of ice, frozen.

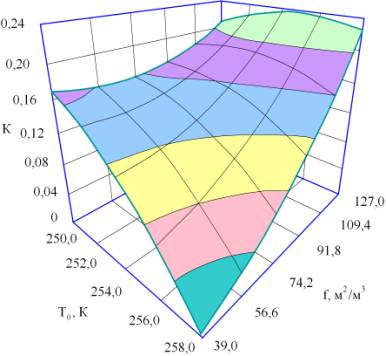

Study

investigated the dependence of the average coefficient of impurity, frozen ice,

which is a ratio of the solids content in ice, frozen to the solids content of

the concentrated solution of the regime factors work chiller plant (Fig. 1-3).

Analyzing

the dependence of the average coefficient of distribution of impurities in

chilled ice from the boiling point of the refrigerant in the evaporator of the

chiller plant should be noted that lowering the boiling point refrigerant

causes a non-linear monotonic increase of solids discharged from the

ice-chilled, which can be explained by the occurrence of quasi-stationary

conditions of the formation of ice crystal structure with Seizure of the liquid

phase and the violation of the terms of the diffusion "rejection" of

cherry juice solids from the crystallization front in large quantities the

temperature difference [1].

Fig. 1. The dependence of the average coefficient of distribution of impurities in the ice chilled

K at a rate of initial product Q = 2 ·10-5 m3/s and the initial solids content of the product

12.5 % of the reflux temperature of

the refrigerant in the evaporator T0, K, and the specific

area heat exchange surface f, m2

mp3

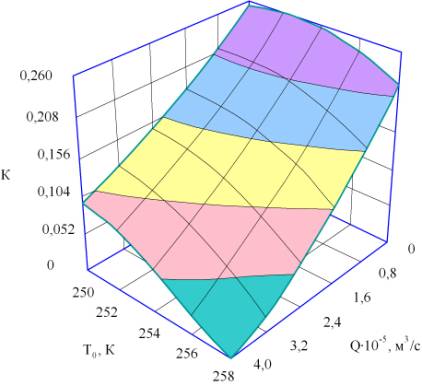

Fig. 2. Dependence of the average

coefficient of distribution of impurities in the ice chilled K for

specific heat exchange surface area

f = 83 m2 / m3 and initial solids content of the product

12.5 % of the reflux temperature of

the refrigerant in the evaporator T0, K, and the initial

product flow Q·m3/s

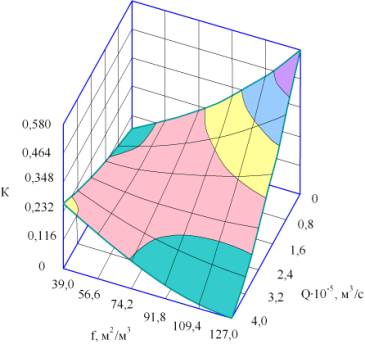

Fig. 3. Dependence of the average

coefficient of distribution of impurities in the ice chilled K at reflux

temperature of the refrigerant in the evaporator T0 = 252 K, the

initial solids content of 12.5 % in the product of the specific heat exchange

surface area f, m2/m3 and consumption of starting

material Q·10-5 m3/c.

Freeze-cherry

juice at boiling temperature of the refrigerant over 258.0 K observed minimum

solids content in the solution obtained by melting ice, frozen.

The

character of changes in the average of the distribution coefficient of

impurities in ice, frozen by the specific surface area of heat exchange

elements and non-linear.

Increasing

the specific surface area of the heat exchange elements causes an increase of

dry matter content in a solution obtained by melting ice chilled cherry juice

during concentration [2].

Investigation

of mean coefficient of distribution of impurities in the flow of ice, frozen

juice fed to the chiller plant is shown that it has a pronounced linear nature.

By increasing the flow of juice into the working space of the chiller plant is

increased in proportion to the quantity of solids discharged to chill with ice.

Literature

1. L. Pap Freeze concentration. Translation.

with Hungarian, edited by O.G. Komyakova. - M.: Light and Food Industry, 1982.

- 97 p.

2.

Ovsyannikov V.Yu. Study of the process of freezing moisture from the extracts

of the endocrine and special raw material. Diss. cand. tech. the sciences.

Voronezh. State. tech. Acad., 2003. 184 p.