Prokofiev P.S.

Volgograd State University of Architecture and Civil Engineering, Russia

High

efficiency humidification

in ventilation and air conditioning

One of the main steps

is temperature and moisture treatment of outside air for common and technological

areas. Humidification units also play role of wash devices, because the water

dissolves gases and smells, catches small parts of dust and freshens the

processed air. Actually, humidification units are additional steps of cleaning

the air. They are irreplaceable in air conditioning systems if you need to

humid air with simultaneous heating. In this case the humidification units are supplied

with coolant temperature is higher than wet bulb temperature of the air.

Adiabatic

humidification is more economical then isothermic, at least in 1-2 times,

whereas in this case the vaporization process is due to internal redistribution

of energy and external energy consumption is due to implementation of various

less costly works. In the most advanced systems of adiabatic humidification

generation of 10 kg moisture takes about 40 Watt of energy consumption.

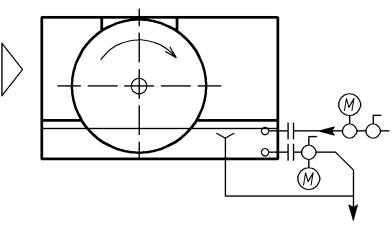

In this article a

fundamentally different design of the adiabatic humidifier is described, called

by the authors [1] as rotary plated heat exchanger (RPHE), construction is

shown in Fig. 1.

Rotary plated

heat exchanger works as follows. Treated air is drawn through the inlet tube into

the case in radial toward the rotating disks and is held in slot channels

between the disks to the outlet tube. When the disks rotate its bottom part is

in the tray with water, when the disk goes up from the tray to air stream due

to surface tension forces on surface of disk the skin of water are formed which

blurs the air across the surface of the disk, and with this skin air processes.

Obviously, the disks should be made of well-wettable material and the surface should

be thoroughly degreased.

RPHE can be

installed on the suction or discharge side of the network, as moisture section

in the central conditioner or in hanging supply units, inside or outside the

attended room. In recent years "Invent Ltd." had carried out

investigations on design optimization of RPHE, and the mass production is

founded in Volgograd.

Fig. 1 Construction of RPHE.

Analysis of most

our projects made for dozens office buildings and malls shows that for most of

them required humidifiers adiabatic efficiency ratio Ea is about 0,8. The value of Ea is calculated by the standard formula:

where t1

– inlet temperature of the air dry bulb, °Ñ;

t2 – outlet temperature of the air dry bulb, °Ñ;

tw –temperature of the treated air wet bulb, °Ñ.

In common the

effectiveness of humidification RPHE depends on the diameter disks, clearance

between its, depth to the water, rotor speed, air velocity and starting parameters

of the air.

RPHE works

without eliminator and air velocity is more than in air coolers, so device can

be mounted in practically any air conditioner, e.g. now “York” firm applies in

their central air conditioners and “Venta” firm in the air conditioners “NOVAIR”.

An important feature of RPHE is the ability to stop humidification at a given

point, it allows to avoid using the second heating.

Problems of humidification

at residential buildings deserve a special consideration. According to most

experts centralized humidification in air conditioning systems of residential

buildings is inappropriate and to solve problems associated with low relative

humidity indoors the most effective is using of individual home humidifiers.

To evaluate the

situation in the SEC "Invent" conducted laboratory tests on domestic

adiabatic humidifiers “VENTA” (Germany) and “AIR-O-SWISS” (Switzerland), that

presented at fig. 3 and 4. At first sight, the design is same, but in fact both

of the humidifier does not have anything in common with RPHE except appearance.

Fig. 2 Experimental sample of RPHE.

Fig. 3 Domestic humidifier “Venta”.

Fig. 4 Domestic humidifier “Air-O-Swiss”.

In both foreign

devices wheels are made of plastic and nonwettable clearance between the disks is

4 and 5 mm. The frequency of the disk is in the range of 1 to 1.5 rpm. To get

wetted surface of disks somehow, in the unit “AIR-O-SWISS” radial tabs are made

on disks that are need for scooping water from the tray. The test results of

humidifiers “VENTA”, “AIR-O-SWISS” and RPHE are presented in table below.

|

Humidifier |

Inlet temperature |

Outlet temperature |

Frequency, rpm |

Ea, % |

||

|

t1, °C |

tì1, °C |

t2, °C |

tì2, °C |

|||

|

|

28,8 |

16,8 |

18,1 |

16,9 |

9,5 |

90 |

|

26,5 |

15,9 |

17,5 |

16,4 |

9,5 |

89 |

|

|

Disks Æ160mm,

clearance 1,35mm, diving 30mm. Total 80 disks. |

||||||

|

|

24,8 |

12,8 |

21,8 |

13,4 |

1,0 |

30 |

|

24,8 |

12,8 |

22,2 |

13,4 |

1,0 |

26 |

|

|

Disks Æ250mm,

clearance 5,0mm, diving 30mm. |

||||||

|

|

24,2 |

12,6 |

23,8 |

12,8 |

1,25 |

5 |

|

24,2 |

12,6 |

24,0 |

12,8 |

1,5 |

6 |

|

|

Disks Æ180mm,

clearance 4,0mm, diving 108mm. |

||||||

As seen, the

coefficient of efficiency in the adiabatic humidification RPHE is

disproportionately higher than of foreign samples. Very low value of Ea of humidifiers “VENTA”

explained not only by the fact that the disks are made of nonwettable material

and fitted with a large clearance, but also by the fact that at the chosen

layout the air is not moving in the clearances between the disks but across the

disks.

Bibliography

1. Author's certificate ¹1216576 «A device for air heat and treatment».