Ñåëüñêîå

õîçÿéñòâî/2. Ìåõàíèçàöèÿ ñåëüñêîãî õîçÿéñòâà

Associate professor Mirzaev B.S.

Tashkent Institute of Irrigation and Melioration, Uzbekistan

Doctor of technical sciences, professor Mamatov F.M.

Karshi Engineering-Economic Institute, Uzbekistan

associate professor Uzakov Z.

Karshi Engineering-Economic

Institute, Uzbekistan

Soil

protection energy-saving technologies and multifunctional unit for tillage and preparation

of soil for sowing

and machine-tractor fleets. In

this case, the coefficient of

efficiency of existing tillers is low, that significantly affects the

cost price of agricultural products.

At present in the Republic of Uzbekistan

lot of attention is paid to the improvement of farming systems and creation of

new techniques for tillage, allowing for more efficient

soil fertility with minimal energy and labor costs.

In

the country in processing and preparation of soil

for sowing are used different sets of technical means

that leads to a significant expansion of the agricultural

machinery park in the farms

In

the agrarian sector of economy of Uzbekistan share of

farms and small farms is equal to 100 %. In this aspect,

emerging technologies and machines must best meet the

modern methods of good housekeeping of farmers. Each unit of purchased or

leased agricultural machinery should be used with best effect.

One of the main reasons of the

low coefficient of tillers

using is ways of processing and preparation of the

soil for sowing. At the present time, the soil

preparation for sowing and sowing of agricultural crops

is carried out mainly by stepwise method, i.e. by

single-purpose machines in several passes. Single-purpose technology of soil

preparation for sowing involves fertilizing, plowing, soil preparation for sowing

(disking, harrowing and etc.). Then the sowing of agricultural crops

is carried out.

On the basic tillage

for agricultural

crops mainly are used traditional general-purpose plows and plows

for bunk plowing. Feature of the technological process of these plows, based on

forking out of soil layers to the side, causes the formation on cultivated fields the breakup furrows and

back ridges. These bumps are typically aligned with the same plows, in four or

more passes, or scraper blade. In terms of a constructive, the main drawback of

traditional plows is the staggered location of its working bodies. With this

location of working bodies, the length of the plow becomes

dependent on the width of capture, wherein takes significantly large value

in the comparison with it. The increasing of the plow length leads

to a sharp increase of the construction metal

capacity.

Thus, the

traditional technologies, from the point of view of agronomy and economy, not justified because

they reduce productivity of labor, increase costs of labor and resources, the

soil is compacted, protracted periods of the soil preparation, the soil dries

rapidly, that leads to the reduction of

agricultural crop yields.

Based

on the foregoing, agriculture must be provided with such machines and units

that meet the following requirements: to provide significant (1.5-3 times)

increasing of labor productivity, reducing of the nomenclature

of machines of 1.5 ... 2 times and fuel

consumption by more than 20%; energy capacity

of operations that are performed by combined units should be lower than the

total energy capacity of the operations of the whole complex of single-purpose machines;

labor costs at the work of combined units should be lower than at the work of the whole complex of the replaceable single-purpose machines.

In our

opinion, multifunctional soil cultivating unit satisfies these

requirements to the full.

In Karshi Engineering-Economic Institute developed

a multifunctional unit on the basis of the combined front plow. It is known

that the front plows differ from traditional plows by the small length, independent of the width of capture, by symmetrical balanced compact design

and low material capacity.

The

feature of the multifunctional unit is the installation

of the exchangeable working bodies on

the carrier system of the machine, ensuring the

processes of both the main and the surface processing of the soil, and the

processing and preparation of soil for sowing of different crops on new

technologies.

Multifunctional tillage unit

provides the following technologies:

-

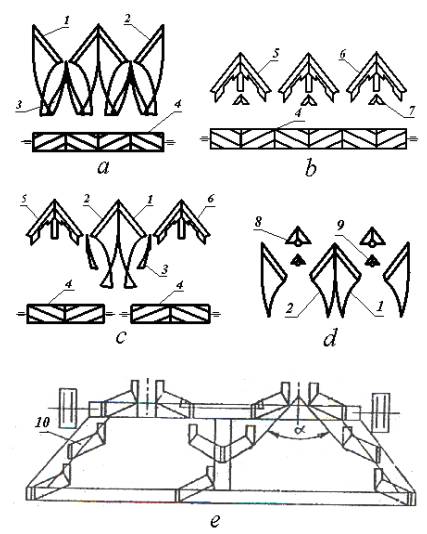

smooth plowing without furrows with the turnover of layer on 1800 within its own furrow. For the

implementation of this technology machine is equipped with frontal established left reversing and right reversing plow bodies 1 and 2, and with after plows 3, which implement

the overturning of layers within its own furrow at 1800 , as well as support-

ripping leveling roller 4 (Fig. 1a). The mounting of the bodies allows changing

the capture width of the bodies, and, consequently, the width of the capture of

machine [1];

Figure 1. The scheme of multifunctional tillage unit.

- moldboardless

tillage, including chisel tillage. At moldboardless

tillage machine is equipped by moldboardless bodies 5

and 6, a frontally mounted on the frame, which implement

the

left reversing and right reversing of soil layers,

and by the packer - leveling roller 4 (Fig. 1b), and for processing by

chisel - loosening working bodies 10 of the "paraglide" type (Fig. 1e) [2];

- moldboardless tillage with band

subsoil loosening of soil, prostrated to wind and water

erosion. The purpose of the band subsoil loosening is to protect the soil from

erosion (retention and accumulation of moisture), the regulation of moisture

supplies, destruction of plow sole and decompression of surface horizon. In

this case, the unit is equipped by the moldboardless left reversing and right reversing bodies 5 and 6, by subsoilers

7 and leveling-packer roller 4 (Fig. 1b) [2];

-

processing and preparation of soil for sowing of melons. To implement this

technology unit is equipped by the symmetrically located left reversing and right reversing bodies 1

and 2 (in the form of listeral body), short after plows 3, rippers for shallow treatment, installed at the sidepiece of

literal body,

subsoilers, wad crusher 4 (Figure 1c ) and by the device

for fertilizing. Rippers 5 and 6 can be carried out in the form of

moldboardless bodies. Subsoiler carried out in the form of

“paraglide" and installed behind bodies (not shown in the scheme) [3];

- processing and

preparation of soil for sowing of corn and cotton on ridges with simultaneous fertilizing. For the implementation of this technology unit

(Figure 1d) is equipped by left reversing

and right reversing bodies 1 and 2 with short

plowshares, rippers 8 and deep rippers 9 with fat conductors, mounted on the axis of symmetry of the oppositely-directed

bodies, wad crusher, made in the form of a convex- concave curve, and the crest doers, as well as a device for fertilizing

(they not shown in the scheme). In this case, rippers and deep

rippers implement loosening on the formed ridge line

by

simultaneous local fertilizing. The left reversing and right reversing bodies,

cutting and wrapping layers towards each other, are pre-formed ridges, then wad

crusher loosens the soil, after that crest doers finally form

ridges [4, 5].

In 2007-2011 years in Kashkadarya region of Uzbekistan held the farm testing of multifunctional tillage machine with

replaceable working bodies made on the basis of the front

plow ÏÔÕ-3. The

unit showed a qualitative and reliable operation at moldboard tillage of the

soil from wheat, in the preparation of the soil from cotton to the ridge sowing

with simultaneous local fertilizing, at reclaimer stockpile

and moldboardless tillage of slopes and at processing

and preparation of the soil for melons sowing.

The feature

of multifunctional unit is its ability to block approach

by wheel and crawler tractors.

Thus, the

new multifunctional machine may perform methods of processing and preparation

of the soil for different cultures with simultaneous fertilizing in the systems

of soil protection and irrigated agriculture in the different conditions in all

periods of field works. The performed tests

have shown that the use of multifunctional combined unit allows reducing labor

costs by 25...28%, fueling costs - by 21…25% and operating costs – by 30...35% in comparison with existing machines.

REFERENCES

1.

Ergashev I.T. Research and justification of the main parameters of combined plow

for a smooth plowing in the conditions of cotton seeds sowing in the

Uzbekistan. The abstract of

dissertation...candidate technical sciences. - M. , 1992.

2. The provisional patent UZ

4044. Tillage unit

//Mamatov F.M. and etc. - Published in Bull. ¹ 1, 1997.

3. Patent UZ IAP 03618.

Combined tool for tillage and seeding //Mamatov F.M. and etc. - Published in Bull. ¹ 4, 2008.

4.

Certificate of authorship SU 1787340. Combined tillage //

Mamatov F.M. and etc. - Published in Bull. I. ¹ 2, 1993.

5.

Patent UZ IAP 03071. Method of soil

preparation for sowing row crops on ridges and furrows //Mamatov F.M. and etc.

- Published in Bull. ¹ 6, 2006.