Key

words:

spot

welds, ultrasonic quality control.

Investigations of spot welds quality

based on ultrasonic techniques

A. Ambroziaka*, M.

Korzeniowskia, P. Kustrońa

a

ul. Łukasiewicza 3/5 50-371

*E-mail

address: andrzej.ambroziak@pwr.wroc.pl

This article contains some information about the main methods of

ultrasonic quality control of spot welds. Resistant welding process is very

sensitive for lots of factors like: electric power excursion, electrodes and

material surface’s condition, electrical by-pass, etc. It usually causes worse

quality of the connection. To prevent this factor’s influence, many methods are

being investigated. Recently, many of the promising methods are based on

ultrasonic waves. That’s why we would like to present advantages and

disadvantages of two systems.

First, OFF-LINE method can give us information about typical

unconformities of spot welds but only after the process. This method is very

popular nowadays especially in thin-walled materials. It lets to check the

quality of even a hundred percents of spot welds without destroying them.

Second ON-LINE method is based on measuring selected parameters of

ultrasonic wave, which flow across the spot-joins during welding process. It

cause that we can check quality of spot weld during its arising. Diagrams of

ultrasonic transmission shows that ultrasonic method can give many, important

information about welding process, like: size of welding nuggets, it’s arising

and crystallization moment but first of all, current switching-off moment. All

abilities of this method can be used to find weld quality, controlling welding

process and prevent many dangerous factors in the time of weld arising.

1. Introduction

The resistance spot welding is the most popular method of joining steel

sheets.

The connection arises by passage the current and action of welding force.

Heating of joining parts is an effect of heat generation on electrical

resistance of welding circuit.

The resistance spot welding is the process of welding by which the

joining parts are pressured by welding electrodes which conduct welding current

into the spot weld [1]. Connecting 2 or 3 parts of sheets is possible by the

resistance spot welding. During this process one or more welding joints can be

obtained. It depends of applied welding machines. The resistance welding

process is quick, efficient. This is the reasons why the spot welding is the

most popular kind of joining in automotive industry (manufacturing bodies,

chairs and many others). The spot welds are mainly performed by robots. Because

of the fact that welding machines are unreliable, spot welds can have some

defects.

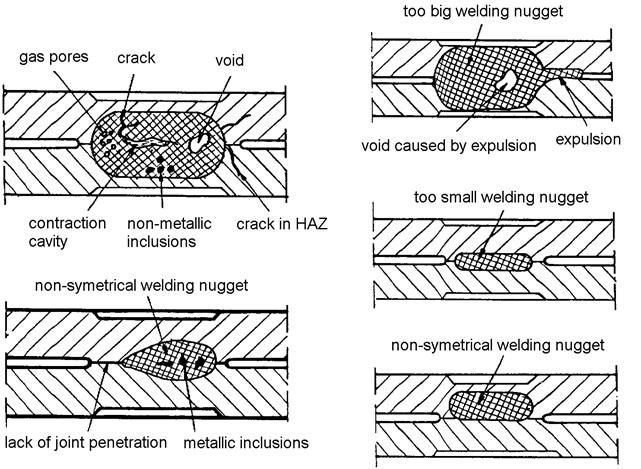

Unconformities which can appear in spot welds causes the spot welds can

have less strength and can lead into total destruction of manufacturing parts.

The typical unconformities of spot welds are [2][3]:

·

cold weld,

·

small-diameter of spot weld,

·

bad shape of the nugget,

·

cracks inside/around the nugget,

·

deep indentation of welding

electrodes in sheets.

Fig.1. Typical flaws in spot welding joints [3].

In automotive industry the elements of cars bodies are joined by

resistance welding. The best quality of welding joints is very important. On-line systems aren’t developed enough, so

at the present it is impossible to control all spot welds.

The non-destructive method which can be applied to test the quality of

spot welds is ultrasonic off-line method. Ultrasonic systems are in common use

from ages, but testing of thin plates generates a lot of problems. The upper

range frequency of typical ultrasonic transducers used to flaws detection is

10MHz. It limits the thickness of the tested plates to 3mm so to test

thin-plate spot welds applying the higher frequency is required. The range of

plate-thickness in automotive industry is from 0.75 to

2. OFF-LINE ultrasonic tests

There are two principal ultrasonic methods used to detect unconformities

inside spot weld. The first one is the pulse-echo method the second one is the

flow method. To test quality of spot welds in automotive industry the

pulse-echo method was used.

This method implicates applying one ultrasonic head worked alternately:

as a transmitter and as receiver.

It

consists of ultrasonic transducer which generates longitudinal vibrations.

Ultrasonic beam flows across the delaying path which is ended by an elastic

membrane.

The homogeneity of spot weld determines the back-wall reflection. The

multiplied reflections are observed at the flaw detector. In case of internal

unconformities (e.g. gas pores) the signal observed at flaw detector is an

effect of reflection from the unconformities.

It’s possible to determine distance from unconformities to ultrasonic

head.

To

determine the quality of spot welds mostly following factors have to be taken into

account:

-

numbers of back-wall reflections,

-

attenuation of ultrasonic wave (in dB),

-

numbers of reflections from flaws,

-

envelope of echoes.

Dimensions of the defects, measured by ultrasonic tests, can diverge

from their real size. It comes from different reflecting ability of variety

reflectors. A shape, diameter and structure of the defects and ultrasonic waves’

parameters are main factors which determine their reflecting ability. Moreover,

a diameter of the ultrasonic transducer and a distance between ultrasonic head

and the defect are very important.

The best reflecting abilities have these planar discontinuities which

are oriented perpendicularly to the wave’s flaw direction.

The experimental spot-welds joints were checked by using the echo

method.

The results of the ultrasonic tests were verified by destructive tests

(metallography).

|

Metallographic picture |

Ultrasonic diagram |

|

Good spot-weld |

|

|

Incomplete

fused joint |

|

Fig.2.

Results of spot-weld inspection [15]

Figure 2 shows two different cases: good and incomplete fused joint. In

the first case, the result of ultrasonic test reveals good quality of the

spot-weld. First diagram shows short sequence and high dumped consecutive

pulses. It testifies about good quality of spot-join. Metallographic test

confirms that fact.

The

second case describes incomplete fused joint. Second diagram shows long and low

dumped sequence of pulses. It proves the lack of the nugget.

3. ON-LINE ULTRASONIC QUALTIY CONTROL

OF SPOT WELDS

Popularity of spot welding process and application of spot welds in

responsible constructions have caused the need of controlling the welding

quality while the process runs. The aim is to minimize the quantity of faulty spot

welds and control the process.

There

are plenty of methods, which allow for quality control of produced joints.

They are mainly base on measuring:

·

current, voltage and dynamic

resistance [10], [11],

·

transmission and velocity of

ultrasonic waves[12][13],

·

thermal expansion [16],

·

infrared radiation [16],

·

acoustic emission [16].

These

methods have a range of advantages and disadvantages. In case of controlling electrodes movement during the

welding, acoustic emission, infrared radiation or ultrasonic method it is

necessary to apply very complicated measuring apparatus.

Method

of measuring dynamic resistance becomes more and more popular [10], [11]

However each of above mentioned methods allows to receive only specific

information about the welding process.

Systems

described below, bases on measuring the amplitude of ultrasonic waves.

There

is a few technological solutions elaborated by different concerns, but its

functioning principles are similar [18] [19].

On

basis of researches conducted by Welding Establishment of Wrocław

University of Technology it has been claimed that, there’s strict correlation

between amplitude of ultrasonic wave measured while welding process and quality

of produced joints.

In application that was used for measuring, ultrasonic heads were placed in

proper construction.

a) b)

b)

Rys. 3. Construction of electrodes

a) scheme , b) picture.

On base of ultrasonic wave transmission curve – measured during the

welding process, we can classify given spot weld to estimated quality category.

The ultrasonic wave transmission curve gives us also a lot of information about

the process that occurs in arising weld joint. Those are eg. forming of liquid

nugget, its growing and becoming a solid phase.

Researches that have been made so far now predicate mainly on measuring

the only one ultrasonic wave parameter – it is transmission of the wave flowing

through arising spot weld. That’s why it is justifiable to pay attention to

other parameters such as velocity and wave passing time from transmitting head

to receiving head, during the welding process.

The

velocity of ultrasonic wave is typical property of medium in which it spreads.

Its value is different for solids, liquids or gases, even for different kinds

of metals. Moreover the relevant factors that determine the velocity of sound

spreading in given mediums are their density and Young’s module.

During the resistance spot welding process

the changes of above mentioned parameters follow, as an effect of substantial

changes of material temperature. Especially Young E module, besides frequently occurs

a change of condensation state (e.g. becoming of liquid spot weld nugget).

Due to this, in compound of arising spot weld, substantial ultrasonic

wave velocity changes will follow, and the same crucial changes of passing time

between transmitting head and receiving head too.

Fig.4. Diagrams

of ultrasonic transmission, received for

(1mm thickness) mild steel and various welding current.

As well as from perspective of produced spot weld quality and from controlling

of this process, the most important area of transmission diagram is current

switch-off moment. According to observed

and registered diagrams, there have been claimed that it illustrates the spot weld

quality in most precisely way.

Figure

4 shows three registered tracks of wave crossing through spot weld while the

jointing process. We may notice that with the welding current growth, also rises

the value of ultrasonic wave transmission.

Fig.5. Time of

flight diagrams, received for

(1mm thickness) mild steel and various welding current.

Figure 5 illustrate the

results of measuring Time of Flight - TOF[ns] of ultrasonic wave through subsequent mediums, these are: liquid

coolant, material of electrode and joined materials. As a result of changes

these mediums’ temperature the wave spreading group velocity also changes. Of

course the time in which the wave reaches receiving head. Due to this, the

direct time measuring has been made actually, and is quoted in nanoseconds

- on figure 5.

Registered diagrams (fig.4 and

5) reflect the spot welds produced with different values of welding current. In

this way have been obtained joints in different quality categories (beginning

with sticking – with welding current Iz = 6,1kA, through to small spot

weld nugget – class C – with welding current Iz = 7,8kA, on perfect one spot weld in A class

ending – welding current Iz = 8,6kA).

4. CONCLUSION

On the ground of presented results, it was found that in spot welds of thin

walled elements:

·

Ultrasonic tests can be apply to

prove their quality

·

Examination requires using special

ultrasonic heads equipped in liquid intermediate medium to improve a contact of

ultrasonic head with spot weld surface,

·

Application of ultrasonic waves

during the spot welding process provides a lot of important information about

arising spot weld and run of the welding process.

·

Ultrasonic quality control is very

promising method but its applying should be verified by metallography.

5. REFERENCES

[1] A. Klimpel: Spawanie zgrzewanie i cięcie

metali, WNT Warszawa1999.

[2] H. Papkala:

Zgrzewanie oporowe metali, WiHK „KaBe” s.c. Krosno, 2003.

[3] A. Klimpel: Kontrola i zapewnienie jakości

w spawalnictwie. WPŚ Gliwice 1998

[4] W. Roye: Die Ultrachall Priifung

von Komponenten und Fugeverbindungen

im Automobilbaum, DGZfP

Berichtband 79-CD, 1999.

[5] R. Rosenberg:

Ultraschallprufung und Dieckenmessung rund ums Automobilbau, Panametrics

Hofheim-Wallau 1999.

[6] Krautkramer Company

Journal „Echo

[7]

A. Lewinska-Romicka: Badania nieniszczące, podstawy defektoskopii, WNT,

Warszawa, 2001.

[8] Ultrachallprufung von

Widerstandspunktschweifiyerbindungen im Karosseriebau der Volkswagen Sachsen

GmbH, DGZfP Berichtband 79-CD, 1999.

[9] C. Kohler: Die Einfuhrung

der Priifung von Widerstandsgeschweifiten Punkten mittels Ultraschall in der

Automobilindustrie – Uberblick der Entwicklungen und Activaten der lezten

Jahre, DGZfP Berichtband 79-CD, 1999.

[10] J. Kozaczyński, Z.

Mikno, P. Stodolny: System do kontroli jakości połączeń

zgrzewanych w oparciu o sieci neuronowe, Seminarium Instytutu Spawalnictwa,

Gliwice, 2004.

[11] A. Straube, A. Torzewski, B. Winien: PQSweld –

System kontroli dla zgrzewania punktowego i

garbowego na bazie fuzzy logic. Podstawy, możliwości i

zastosowania praktyczne, Seminarium

Instytutu Spawalnictwa, Gliwice, 2004.

[12] A. Ambroziak, Z.

Koralewicz, M. Korzeniowski, P. Kustroń: Kontrola jakości powstających zgrzein metodą ultradźwiękową, Prace Naukowe

Instytutu Technologii Maszyn i Automatyzacji PWr., Zeszyt nr 73.

[13] A. Ambroziak, L. Krynicki, Z. Koralewicz: Określenie

przydatności badań ultradźwiękowych do oceny jakości

połączeń zgrzewanych punktowo, Przegląd Spawalnictwa Nr

7-8/2000.

[14] A. Ambroziak, Z.

Koralewicz, M. Korzeniowski, P. Kustroń: Badania ultradźwiękowe

zgrzein punktowych, Spajanie metali i tworzyw w praktyce,

Nr 1/2005.

[15] A. Ambroziak, A. Kisiel, M. Korzeniowski:

Zastosowanie badań ultradźwiękowych do oceny zgrzein w

cienkościennych elementach stalowych, Przegląd Spawalnictwa 5-7/2004.

[16] S. Piech: Kontrola adaptacyjna w procesie zgrzewania oporowego

punktowego, Przegląd Spawalnictwa, nr 5/1983.

[17] E. Talarczyk: Podstawy techniki ultradźwięków, Wydawnictwo

Politechniki Wrocławskiej, 1990.

[18] VOGT

Werkstoffprüfsysteme: Inline

ultrasonic testing system for process control during resistance spot welding, www.vogt-ndt.de.

[19] Bosh Rexroth: Automatic

ultrasonic tests – non destructive during the welding process, Materiały

konferencyjne,