Operating

damages of air turbine scoops of turbo - engines

Ph.D. D.Sc. Janusz Szymczak, Ph.D. D.Sc. Andrzej Szczepankowski

Air Force Institute of

Technology (ITWL)

6 Ksiecia Boleslawa

St., P.O. Box 96, 01-494 Warsaw 46, Poland

tel.:+48 22 6852210,

e-mail: assz@op.pl

Abstract

The paper presents various types of

turbine scoops damages that are being found in the operating process of air turbine

engines (TSO). When dividing them, having in mind a genesis of their origin, a

special attention has been paid to corrosion and high-temperature erosion,

often being a reason for destruction of the entire unit.

The damages hereto described have

been illustrated with examples collected during endoscope surveys of TSO internal

spaces or their post-failure disassembly. The summary points out to the ways

and directions of works aiming at early detection of TSO turbines units

damages, and thus at improvement of their operating safety.

Key words: turbo-jet engine, turbine, damages,

corrosion, erosion, operation, prevention.

Introduction

Many years of experiences and

observations as well as a result of air accidents investigations, performed by

the authors of this paper, have indicated that in the air TSO operating process

there are various types of scoops blades damages of turbine units, thus

limiting technical installation life. Their causes can generally be divided

into: construction design-based, productive, and operating. And the latter ones

into: mechanical, chemical, and thermal. They may become centres of wearing

cracks of one or more of scoop blades and a cause for their partial or total

destruction, which in turn often leads to damages of those neighbouring with

them in the blade-ring or in the subsequent levels of the turbine unit. In a

consequence it results in engine failure, premature dismounting thereof from

airframe and ordering it to be repaired.

Also wearing cracks, mechanical and

thermal deformations, overheatings and burnouts or chemical corrosion as well

as mechanical and gas erosion are the main cause for premature withdrawal of

TSO from use, and not detected in proper time can become a danger for their

users.

This paper presents various types of

examples, being found in the operating process, and blades damages of TSO air

turbines units.

Damages effecting from a design of

turbine rotor ring

Wanting to obtain the

largest possible efficiency of TSO turbine level, various types of solution

designs are applied which, on the one hand, by minimising tip clearance reduce

loses of working medium flowing through it, and on the other hand, they stiffen

the rotor ring.

1

Fig.

1a. View in direction of a surface of cooperation between two, neighbouring in

a ring and coming subsequently one after the other, locks of plates of node

shroud of scoops blades of 3rd level rotor of „89” type of engine turbine [1,

6], 1 - a cooperation surface of

distance plates of node shroud locks

One of such

solutions has been illustrated on Fig. 1a where by using node shroud plates

(anti-vibration plates) of blades, having a complicated lock shape with

distancing plates melted-in during the TSO production or repair process in

place of cooperation of the turbine level scoops neighbouring with each other

in a ring, and by introducing initial torsional stresses (assembly tension)

when building them into a carrying disk, its ring tightening has been achieved.

However, when using this type of

engine, such a solution design results in a need to realise its technological

regeneration process that is not less complicated.

![]()

![]()

![]()

Fig. 1b. View of

external surface of node shroud plates of operating scoops of 3rd level of a turbine of „89” type of engine [1] (1 - raw material of distance plate type 89.0420148.2, 2 - raw material of distance plate type

EG89.041421)

During TSO operation, as a result of natural

wearing of distance plates of the node shroud in places of their cooperation

(see - Fig. 1a, e) or mechanical damages caused by their chipping off, there is

an increase of total, circumferential assembly clearance and of such values

that may generate resonant-alike vibrations or even resonant vibrations in the

ring.

![]()

![]()

![]()

Fig. 1e. View of 3rd

level of turbine rotor of „89” type of engine. c ÷ d - the remaining in

the carrying disk fragment of multi-trapezoidal lock of a scoop broken out from

the ring [1]

This in turn may result both in the carrying

disk lock itself and under the plate of blade shroud in a growth of stresses to

critical values. Therefore, it is not difficult to figure it out that exceeding

them may cause initiation of wearing cracks that as the end result will lead to

breaking out one of the scoops from the lock of the carrying disk and to a

damage of a turbine unit (see - Fig. 1c ÷ e) [1].

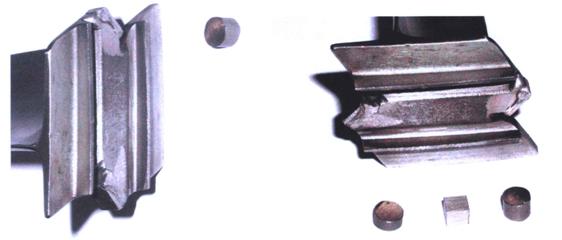

Production

and repair causes of turbines scoops damages

Those types of damages rarely occur in air TSO. Nevertheless, it

happened over the past few years that two cases occurred that entire blades of

scoops broke out from rings of rotors of SO-3 type of engines - see Fig. 2a. As

a result of the-then conducted investigations it was found that the cause of

that was an error made in their production process, as not only that blades of

scoops were covered with chromo-alliterated layer but also their

multi-trapezoidal locks. This led to increasing local surface stresses in locks

spaces and to generation of microcracks (see - Fig. 2b), which in consequence,

as a result of TSO operation, caused breaking out of one of scoops blades in a carrying disk lock of the

rotor unit.

|

|

|

|

Fig. 2. Fragment of

turbine rotor of SO-3 type of engine with a scoop broken out from the ring

(a). Crack of the scoop on the radius of a passage of the blade neck into a

multi-trapezoidal lock (b) [6] |

|

However, such cases occur as that

illustrated on Fig. 3 when first a burnout of insulation-protective layer had been

found on the surface of the edge of the scoop blade of the high-pressure

turbine rotor TSO (see - Fig. 3a), and then after it was repaired the same

scoop looked as the one illustrated on Fig. 3b, which already may raise some

doubts of the user as to quality of the performed improvement of the exemplary

element or its regeneration technology itself.

![]()

![]()

Fig. 3. Fragment of

high-pressure turbine rotor of „88” type of engine [6]. a - burnout of

insulation-protective layer from the part of the blade attack edge surface, b -

view of the fragment of repaired scoop blade

And this type of doubts could have

been raised by earlier supervision of the use of AI-25 type of engines and the

example of which has been illustrated on Fig. 4.

On the surface of the

scoop preceding the damaged one, there is a clearly visible „surface

discontinuity”, which only means that during the renovation the old

insulation-protective layer was not cleared from it but only the damaged part

was filled in without caring for a correct operation of that of the working

injectors whose operating quality influenced its earlier condition.

![]()

![]()

Fig. 4. Fragment of a palisade of steering gear of

high-pressure turbine of AI-25 type of engine [2]. a - burnout of

insulation-protective layer from attack edge surface and the blade rim, b -

view of the fragment of repaired scoop blade with high-temperature corrosion

pits

However, it did not protect it from

damage as after some time high-temperature corrosion craters were found on its

surface - see - Fig. 4b.

Mechanical

damages of turbine scoops

Long-term visual

research using endoscope method and related to them analysis of technical

status of TSO subcomponents allows for making some generalisations referring to

initiation of their damages. Therefore, events effecting from sucking in

foreign matters should be considered to be the basic cause of mechanical

damages of compressor and turbine unit. It happens on the random basis or it

results from taking off or landing on casual landing grounds. Nevertheless, one

also cannot ignore here a lack of proper carefulness of technical personnel for

keeping ground surface clear, or engine intake. However, there are such cases

the cause of which may also be incorrectly made protective coating and its

later erosion damages.

![]()

![]()

![]()

Fig. 5. Fragment of turbine rotor of high (a ¸ b)

and low (c) pressure type of engine „88” [3, 6]. a - a dent on a surface of

blade attack edge, b - a dent on a surface of the rim (close to the edge of the

blade flow) and c - numerous, small-area dents on a surface of the blade rim

And the fact that those types of damages are rather typical for TSO

compressors units does not necessarily mean that they are not found on turbines

scoops, as dents occur also on their surfaces (see - Fig. 5), or scratches of

insulation-protective layer thus becoming a source of local concentration of

tresses or a corrosion centre, which in this case as on Fig. 6 may lead after

some time to perforations and cracking of the blade.

![]()

Fig. 6. Scratch of

insulation-protective layer with

Fig. 7. A dent of the rim surface with a simultaneous

with corrosion centre on the surface

of attack buckling of

attack edge of scoop of turbine rotor

edge of the scoop blade of high

pressure of

SO-3 type of engine [6]

turbine rotor of „88” type of engine [6]

This type of damages

does not necessarily have to effect from sucking in of foreign matters by TSO,

as the same may be caused by tearing off products of incomplete combustion

(carbon deposits) in the combustion chamber and their crashes with turbine unit

elements, as it happened in case illustrated on Fig. 7.

Thermal

damages of turbines scoops

The source of damages, illustrated on Fig. 8 b ÷ c, was an

incorrect organisation of the combustion process as during operation of the

engine there was an occurrence of a local, short-lasting lengthening of the blend

combustion zone and its relocation in direction of further sections of

combustion chamber flame tube, thus giving a cause to possible further burning

of fuel vapours in a space of palisade of steering gears during ignition of

TSO. Changes in the surface status that have been found in those places prove

how significantly the process was going through periodical interference.

However, in case of this type of TSO, it is easier thanks to a construction

design of combustion chamber unit itself because nozzles axles of operating

injectors face in it straight towards bottom sediment rings of steering gears.

|

|

|

|

|

Fig. 8. Fragment of fuel

injector and palisade of steering gears of high-pressure turbine of air

turbo-engine type AI-25 [6]. Subsequent phases

b ÷ c of corrosion-erosion „washout” of material of bottom feet of locks

of two steering gears blades neighbouring with each other in a palisade

It is essential

as at simultaneous, incorrect match of nozzles diameters, or when surfaces of

operating injectors had carbon deposits (Fig. 8a) and thus effecting in a

change of geometry of fuel spray cone, first there was an occurrence of

overheating and burning out of insulation-protective layer in those observed

places, and later of a gradual and „up to disappearance” of a part of the blade

(Fig. 8d), „washout” of its material, which was not even prevented by the fact

that they are cooled with air taken from compressor space.

The fact that the above-presented process of TSO destruction was going

in a long period of time, and which probably had already started at the moment

of its delivery to use, is proved by traces of corrosion and gas erosion as one

of its forms was the aforementioned „washout” of material from parts of

surfaces neighbouring with each other in a palisade of steering gear blades

(Fig. 8c). This was also accelerated by allowable presence of residual amounts

of W, Mo or Co, and first of all sulphur compounds in fuel, as Jet A-1 (F-35)

type of aviation fuel, being produced in compliance with military defence standards,

may contain a maximum up to 0.3% of S in its volume unit, and this in turn

causes that SO2 contents in combustion fumes may even reach ca.

0.014% [4]. This leads to a conclusion that the higher contents of this element

in fuel the higher contents of SO2 and SO3 in combustion

fumes, which in turn results in a higher threat of turbines damages in view of

inter alia incorrect organisation of its combustion process.

Chemical damages of

turbines scoops

Chemical damages of turbines scoops

are first of all corrosion leading to surface pits and in its consequence

cracks of blades.

![]()

![]()

Fig. 9. View of

fragment of the scoop blade groove of turbine rotor of SO-3 type of engine used

in environment of

higher contents of sodium chloride [6]. Two subsequently commencing

phases one after the other a) ÷ b) development

of sulfide-oxide corrosion

A failure

in the production or repair process to observe respective parameters for

putting protective layers also has a large impact on generation and development

of this type of damages as that in case of the illustration presented on Fig. 9

was a likely cause of occurrence of the damages found. This is proved not only

by their character but also by location of their occurrence because they are

found on those surfaces which are the most exposed to influence of temperature

and contents of the flowing combustion fumes, that is, on the attack edges and

the groove. It should however be added here that the working environment itself

of TSO being tested also had some influence on acceleration of this process,

which in this case indicated a large content of sodium chloride.

The above picture was used to

illustrate recognised in references [4] two first phases of development of this

type of corrosion, however, on Fig. 9a there is a visible fragment of surface

the protective layer of which has been damaged still on a small area, and being

characterised with a small growth of its roughness and just cracking oxides

bubbles. However on Fig. 9b, it is noticed that the extension of the work time

of the scoop in the aforementioned conditions led to further development of

oxidation of its protective layer and it growing roughness, and due to the fact

that its bedding had also been damaged it already resulted in a start of depreciation

of chrome from deeper layers of the alloy.

Describing a development of gas

corrosion of those alloys that are used for making turbines elements, it should

be divided into a few phases from which the most important are those chemical

reactions that occur on borders of phases: metal - oxides and oxides – atmosphere

and diffusion of reagents through a layer of products being created on their surfaces.

But when describing what speed of development of this type of corrosions

depends upon, it should be first of all stated whether there is a compact, as

on Fig. 9, or porous, as on Fig. 10 layer of corrosion products being created

on the alloy surface, as in the first case it may become a protective action,

and corrosion speed is then dependant on diffusion of reagents in oxide layer

and it is the most often the reversely proportional to the layer thickness.

However, along with growing

intensity of corrosion development, a layer is created on the surface of the

chromo-nickel alloy and a layer of characteristic properties keeps growing as

on its border line eutectic mixture Ni3S2 – Ni occurs,

then above it the one consisting of oxides of such improving additives as: Cr,

Al, Ti, W and Mo, and below it sulfides [7]. However, the contents of sulfides

in nickel alloys with higher resistance to corrosion usually differ from those

that corrode at a fast speed, as among identified then corrosion products e.g.

(Cr, Ti)3S4, CrS, (Cr, Ni, Ti)3S4,

(Cr, Ni)3S4, (Cr, Al, Mo)3S4, and

Ni3S2, the first three are more stable than the others

and they are the most commonly occurring among products of low sulfide-oxide

corrosion intensity. Therefore, in order to obtain such a status that would indicate

high growing intensity of its products, and thus creation of sulfides e.g. Ni2S,

Ni3S2, or (Cr, Al, Mo)3S4, that is

the ones allowing for easier „washout” of material, activeness of sulphur

should be increased in a working environment of the investigated element [7].

Many years of our

experiences show that it may happen as a result of cyclical switching TSO on

and off, as it takes place in case of those engines that are used by military

air force, because it is then, also as a result of incomplete combustion of

fuel in them, a possibility occurs, for instance, of contamination with carbon

from melted sediments, and already for some time covering the surfaces of

blades of turbines scoops, and as a consequence of which one of the

high-temperature erosion symptoms may occur, namely e.g. a gradual vaporisation

(„washout”) of the surface layer of the supervised subcomponent.

![]()

Fig. 10.

Fragment of the scoop blade of high-pressure turbine rotor of AI - 24WT of type engine [6] a)

Sulfide-oxide corrosion centre on the attack edge of the blade b) Corrosion

pits and losses of material caused by its chipping off on the attack edge

of the blade

![]()

Regardless of a variety of

morphological signs of this type of corrosion, one may differentiate in this

type of surface layer a simultaneous presence of its products, namely oxides

and sulfides, however, the first ones will be found in the outer layer while

the second ones in a phase directly adhering to the original alloy and in time

a trend aiming at reduction of the contents of the first ones in the outer

layer and increase in its depth, and the second ones in a reverse direction.

This should be used to explain occurrence of the eutectic mixture Ni3S2

- Ni at the border of the corrosion layer and the alloy original material, and

at intensive development of this process, also a presence of oxides NiO and NiMo4

and „being washed out, or vapourised” by the flowing combustion fumes of

sulfides Ni3S2.

Another form of a local damage of

the hereto discussed unit in conditions close to the previous ones is

intercrystalline corrosion, and changing chemical contents of the alloy at the

border of grains. Its development, similarly to that of the former one, is

facilitated by its operation in environment containing inter alia sodium

sulfate and that in temperature higher than 1050 K. It affects mostly alloys

with nickel, cobalt, and iron coating, however, this corrodibility is lowered

in them by higher contents of Cr, and increased in a relatively fast pace by

higher concentration of sodium chloride. But our experiences indicate that an

increase of a tendency of this type o alloys to intercrystalline corrosion is

highly influenced by work of a device in changing temperature conditions and

periodically exceeding its allowable value, which results in lower contents of

chrome in the material overheating zone and presence of relatively large

carbides on the grains border. So, further operation of the turbine unit in

those conditions leads inter alia to a local chipping off caused by flowing

combustion fumes of surface layer products (Fig. 9 and 10) [4, 6, 7].

Summary

Despite more than centennial

development of construction designs and production technologies of internal

combustion turbines, still various types of problems appear, and damages

occurring and conditioned by many reasons not only that limit their

installation life but also pose a threat on their use safety, or flights safety

itself.

By undertaking various types of

preventive actions, such as those aiming at improvement of air TSO use safety,

visual surveys are made inter alia of the surface status of elements from spaces

of internal turbine units with a simultaneous recording of changes found. Therefore,

after damage has been found not only it will be accompanied by a shortened time

horizon until the next survey but by monitoring of occurring changes.

However, this is a

complex process as the above-described damages of turbines scoops blades should

also be prevented by development of new production technologies, including

putting multi-layer preventive-insulation coatings on their surfaces. It

appears, however, that they may only slow down the process, which may be

illustrated by an example on Fig. 11 of the destruction process of one of the

scoops of high-pressure turbine rotor ring of „88” type of engine [6].

![]()

![]()

![]()

![]()

![]()

![]()

Fig. 11. Fragment

of the scoop of high-pressure turbine rotor of „88” type of engine [6].

Subsequently following after each other a)

÷ f) phases of degradation of turbine

rotor scoop blade

On Fig. 11 (a ÷ b), visible

are damages of the surface protective layer of the blade attack edge, however,

their surface area grows alongside of the height of the scoop together with a

number of hours worked by TSO (Fig. 11b). So, after the engine has operated for

another 25 hours and in conditions close to the former ones, it is noticed

(Fig. 11c) that on a certain area of the blade it is not only that the surface

protective layer is missing but also the one insulating it from original

material of the scoop. We knew, however, that the engine had worked about 80

hours until that time starting from the day it was built into the airframe, and

the damage found not only referred to the one scoop blade in the rotor, but to

about 80% of the supervised turbine ring, which in turn could only co prove

inefficiency of its cooling system or one of the fuel injectors.

Nevertheless, the engine was still

being used as based on our gathered experiences it seems that in the next phase

of the blade destruction an occurrence of corrosion pits in the original

material of the scoop (Fig. 11d) will be noticed in the earlier damaged spots,

and after TSO has worked a further number of hours it will be found that its

attack edge has already been perforated (Fig. 11e), and that already poses a

threat on safety of its use as in the next phase it would lead to breaking out

of part of its blade (Fig. 11f). Therefore, in the hereto described case the

engine operating process has been ended at the phase illustrated on Fig. 11d.

Research testing and production of

new materials and improvement of construction designs of turbines units, and

thus their cooling systems, or technology of making thermal barriers have been

and will continue to be new challenges for a great number of scientists and engineers.

However, finding their solutions, and in particular in aviation already exceeds

financial possibilities not only of single research teams but those of entire

countries. Therefore, as proven by numerous examples, in this case a

well-organised international cooperation is essential.

References:

[1]

Szymczak J., Szczepankowski A., „Sprawozdanie

ITWL nr 35/34/2004” (unpublished), Warsaw 2004;

[2] „Sprawozdanie

ITWL nr 12/34/2005” (unpublished), Warsaw 2005;

[3] „Sprawozdanie

ITWL nr 73/34/2007” (unpublished), Warsaw 2007;

[4] Olzak B.,

Szymczak J., Szczepankowski A., „Gasaeus

erosion and corrosion of turbines”, V Internacional Scientific - Technical

Conference, Gdansk - Stockholm - Tumba 2007;

[5] Szymczak J.,

Szczepankowski A., „Badania

endoskopowe w ocenie

degradacji elementów wewnętrznych wirnikowych

maszyn przepływowych”, X

Jubileuszowy Kongres Eksploatacji Urządzeń Technicznych”,

Stare Jabłonki 2005;

[6] Baza danych Zakładu Silników

Lotniczych ITWL (unpublished);

[7] Nikitin, W. I., Korrozija i zaszczita łopatok gazowych turbin, Leningrad 1987.