Tåõíè÷åñêèå íàóêè/ Àâèàöèÿ è êîñìîíàâòèêà

Nickolay Zosimovych, Achhaibar Singh

Sharda University (Greater Noida, India, UP)

CONSTRUCTION

OF AN ALGORITHM DETERMINING THE OPTIMAL TOLERANCE FOR THE DESIGN OF UAV

As a

result of perfection of forms modern and perspective Unmanned Aerial Vehicle

(UAV) of typical geometrical parameters of a surface have been made the

technique of appointment of admissions and criteria for tolerances external surfaces on

external surfaces is offered. That allowed us to build the algorithm and applied computer program for

solving the task to choosing optimal tolerance for the UAV external surfaces.

Key

words: Unmanned Aerial Vehicle

(UAV), surface, aerodynamic quality, sinuosity, technological roughness’s, ledge, constructive and technological

actions, fuselage, fuel consumption, specifications, performance, manufacturing,

maintenance, cost, lifecycle, technical requirements (TR),

design

and technology implementations.

Introduction. Increase

of efficiency of UAV is caused, on the one side, by a problem of fuel

resources, and with another side a tendency of change of structure of expenses

for life cycle aside reduction of a share of initial UAV cost. Aircraft

engineering practice marks following basic ways of increase of UAV efficiency [1]:

1. Application of

essentially new constructive decisions and materials (10-20%).

2.

Perfection of engines (20-30 %).

3.

Aerodynamics perfection (0-40 %).

The importance and urgency of improving the aerodynamic efficiency by improving the forms of modern and advanced UAV, including by improving the quality of exterior surfaces, confirmed by the entire history of aviation. Detailed consideration of

dependence of resistance on quality of performance of external surfaces by

manufacturing shows that additional resistance can reach 2-10% at zero upward force

[2]. The greatest share is brought by the deviations increasing a lateral

section, details for example acting in a stream (approximately 5 %). Nearly

1.2-1.5 % is necessary on rivets and bolts connections; 0.5 % on joints of

sheets; 1.0-1.5 % leaky position of shutters and hatches gives; rough coloring

(over 20 microns) – up to ![]() At speed above Ì=1.5, the size of all components increases approximately twice and

resistance from a sinuosity - more than 5 times. For the reasons specified

above, the resistance increase through technological roughness is for subsonic UAV

makes approximately 5-6 %, and for supersonic (Ì=2-3) – 10-16% [2].

At speed above Ì=1.5, the size of all components increases approximately twice and

resistance from a sinuosity - more than 5 times. For the reasons specified

above, the resistance increase through technological roughness is for subsonic UAV

makes approximately 5-6 %, and for supersonic (Ì=2-3) – 10-16% [2].

Perfection

of quality of external surfaces, due

to constructive and technological actions,

can lead to additional expenses. Therefore,

an important question at definition of quality of external surfaces, quantitative

estimations of similar actions. As such criterion for a quantitative estimation

of losses from additional resistance it is possible to accept the expense or

fuel cost. The expediency of an estimation of such kind is obvious, as fuel

consumption is unique precisely measured parameter at the given design stage UAV,

directly reflecting infringement of aerodynamics of a surface, both in

manufacture, and in operation [3].

Problem statement. In development of designs UAV

and, accordingly, technologies of their manufacture always crucial importance

had constant increase in speeds of flight [1]. Growth of speeds of flight not

only causes of application of new, more and more heat-resistant materials, but

also is accompanied still nearby important for development of the production

technology of tendencies [4].

Deviation

of elements of a surface from a theoretical contour, a raising of heads of

bolts, rivets, screws in a stream, steps, a roughness etc. on everyone concrete

FV or group of planes are appointed in specifications developers.

Results of researches. By working out of

constructive and technological decisions it is necessary to define the

requirements shown to quality of object of manufacture and technological

processes, in particular to appoint maximum deviations of aerodynamic surfaces.

Admissions on a relative positioning of global surfaces of separate units and

units among themselves in this case are not considered.

1. Technique

of appointment of admissions on external contours of flying vehicles. For the purpose of definition of a generality of the constructive and

technological decisions accepted in specifications, revealing of the reasons

defining size of the admission have been analyzed specifications for more 30 FV

various types and appointment [5].

2. Criteria for choosing tolerances for contours of the UAV. Qualitative performance indicator, as noted in [1], is a ratio impact

on target impact cost to the whole lifecycle ![]() is

is ![]() As for since

the cost of surface quality of a targeted

output are generally, does not change

As for since

the cost of surface quality of a targeted

output are generally, does not change ![]() the improvement in the efficiency is possible by changing the value of the life cycle. Hence the

condition for as a selection criterion of tolerance

is assumed as [6]:

the improvement in the efficiency is possible by changing the value of the life cycle. Hence the

condition for as a selection criterion of tolerance

is assumed as [6]:

![]() (1)

(1)

where ![]() manufacturing cost;

manufacturing cost; ![]() maintenance costs

for the entire

lifecycle, equal

to

maintenance costs

for the entire

lifecycle, equal

to ![]()

![]() staff salaries;

staff salaries; ![]() the cost of ground

handling and support

of UAV flights;

the cost of ground

handling and support

of UAV flights; ![]() the cost of UAV repairing;

the cost of UAV repairing; ![]() fuel costs.

fuel costs.

Surface quality a direct impact on UAV fuel costs, because

deviations from ideal surface in majority cases helps to increase the resistance at zero lift, i.e. ![]() Whereas

Whereas ![]() where

where ![]()

![]() range (field)

error.

range (field)

error.

3. The factors

determining value

for admission to contours of the UAV. The

magnitude of external outline tolerance

influences range of factors which determine the value derived from operating costs which depend on the quality the external surface is defined as the cost

of an additional fuel [3]:

(2)

(2)

where ![]() hours

fuel consumption;

hours

fuel consumption; ![]() increment value of

resistance due to surface

defects.

increment value of

resistance due to surface

defects.

In order to reduce the amount of calculations

for comparing various design and

technological solutions, the

concept of costs per unit of

surface area ($/m2) is introduced [7]:

Taking into account the additional resistance for irregularities such as wave,

step, slit, etc., can be described by the following equation:

![]() (3)

(3)

where ![]() drag coefficient of

isolated irregularities;

drag coefficient of

isolated irregularities; ![]() functions reflecting the influence of speed and altitude;

functions reflecting the influence of speed and altitude; ![]() maximum height of the surface that is equal to scale of error;

maximum height of the surface that is equal to scale of error; ![]() the coordinate characteristic

parameter roughness (in m, for example, maximum amplitude of wave, a step, etc.);

the coordinate characteristic

parameter roughness (in m, for example, maximum amplitude of wave, a step, etc.); ![]() relative area

occupied by roughness of investigated;

relative area

occupied by roughness of investigated; ![]() the exponents.

the exponents.

According to the equations (2) and (3):

![]() (4)

(4)

where ![]()

Thus the additional cycle costs are defined by basic parameters of UAV and conditions of its exploitation. Expenses

of manufacturing, in general, depend on pre-production method adopted; level of the cost of one hour defined by accepted methods and means. In general, this set of

determines the technological solutions

which used to implement the some

set design solutions.

Establishment of functional relation between cost of production and size of the construction errors are self-task. The present paper

considers only the final results to

principal design solutions. Proceeding

from the results of statistical analysis, manufacturing

costs may be given as:

![]() (5)

(5)

These equations (1), (4) and (5) allow establishing

a quantitative correlation

between the described forms factors, i.e. to present the process of choice of tolerances as mathematical models.

Presented

equations (1), (4) and (5) enable us to establish the quantitative relationship

between the described form factors and define the process of selecting

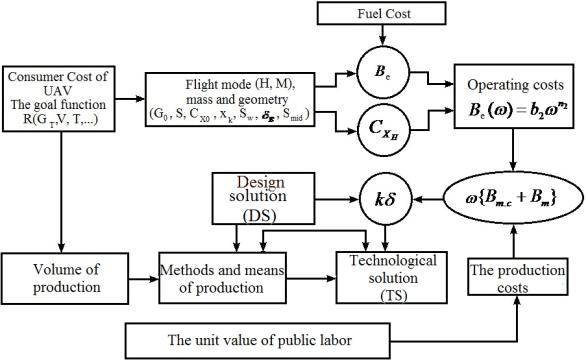

tolerances as a mathematical model (Fig. 1) [8].

Fig. 1. The

structure of the mathematical models of choice the tolerance on the external

contours

In

general this MM should be supplemented by description of effects of external

factors ![]() on the goal function,

represented in the form of fuel prices, the unit cost of labor, etc. [9]. The

optimal value of tolerance according to accepted criteria given by the equation

[10]:

on the goal function,

represented in the form of fuel prices, the unit cost of labor, etc. [9]. The

optimal value of tolerance according to accepted criteria given by the equation

[10]:

(6)

(6)

using which one can

find an estimate of each factor relative to the base value, i.e.

(7)

(7)

The equation

(7) allows recalculating the tolerance when you change the flight modes, design

and technology implementations and external conditions. For example, the

service life changes is determined by the ratio ![]() [7,9]. Then for

[7,9]. Then for ![]() a close tolerance as

a close tolerance as ![]() is needed. Influence of the

speed estimated by the flight ratio [1]:

is needed. Influence of the

speed estimated by the flight ratio [1]:

(9)

(9)

In the case

of monotonic change incoming parameters ![]() required for the tolerance with

toughening of the rising of

required for the tolerance with

toughening of the rising of ![]() For the solution problems of

choosing the tolerance (especially in the case of iterate options), for

example, more than 30 and the various flight conditions we can use the

algorithm and program of calculation developed by the authors based on the

proposed mathematical model.

For the solution problems of

choosing the tolerance (especially in the case of iterate options), for

example, more than 30 and the various flight conditions we can use the

algorithm and program of calculation developed by the authors based on the

proposed mathematical model.

4. Construction of an algorithm determining the

optimal tolerance for the design of UAV. The procedure of determination

the optimal tolerance by ![]() for a particular design solution must be performed in solving tasks

enumerated in the previous section.

for a particular design solution must be performed in solving tasks

enumerated in the previous section.

In

order to prepare the information and as a basis for the calculation must be

taken of (2) and (3) that characterize the influence of various factors on the

operating costs, and the equations describing the effect of structural and

technological factors (STF) (5). The final result of the calculation should be

formed as an array of data elements of optimal tolerances for different STF as

a result of the solution of (6) [7].

The sequence of calculations

1. Determine the typical

design solutions, the area of their placement on UAV ![]() coordinates

coordinates ![]()

2. Find the possible

technological implementations and parameters ![]() and

and ![]() depending from expenses for

manufacturing tolerances.

depending from expenses for

manufacturing tolerances.

3. Find the specific

geometrical parameters of roughness ![]() or

or  in the case waviness – the allowable

wavelength [1].

in the case waviness – the allowable

wavelength [1].

4. Determine normative

data depending on the type of UAV and flight mode: ![]() and compute

and compute

5. For the researched define

species roughness coefficient ![]() which takes into account the

probabilistic nature of value

which takes into account the

probabilistic nature of value ![]()

6. Calculate

parameters ![]() and

and ![]() For obtain the waviness

For obtain the waviness ![]()

![]() For the remaining unevenness

For the remaining unevenness

![]()

![]()

7.

Compute the

8. Check the

possibility of realization ![]()

9. Compute the

quantities of losses or effect compared with the analogue as the difference

between the above costs, i.e. ![]()

![]()

Conclusion. The analysis of appointment of

admissions on external surfaces of units UAV, practice of their appointment and

realization in manufacture allow drawing following conclusions:

1. Practically UAV in

one interval of numbers![]() admissions on performance of geometrical elements of an external

surface are identical to all and decrease with growth

admissions on performance of geometrical elements of an external

surface are identical to all and decrease with growth ![]() The highest requirements to quality of an

external surface are shown to a wing, as to the unit creating carrying force.

The highest requirements to quality of an

external surface are shown to a wing, as to the unit creating carrying force.

2. Experimental

researches of the isolated roughness are put in a basis of calculation of

resistance from roughness’s taking into account its site in the boundary layer.

The roughness height is defined by admissible size of additional resistance![]() . Practical technique to an establishment of dependences and functional

communications between values of admissions and expenses by the generalized

criterion and consequently, and to a choice of economically optimum admissions,

still it is not defined unequivocally. Therefore for the generalized criterion

accept additional fuel consumption because of resistance of roughnesses, as

influence of additional resistance on speed almost slightly.

. Practical technique to an establishment of dependences and functional

communications between values of admissions and expenses by the generalized

criterion and consequently, and to a choice of economically optimum admissions,

still it is not defined unequivocally. Therefore for the generalized criterion

accept additional fuel consumption because of resistance of roughnesses, as

influence of additional resistance on speed almost slightly.

3.

Thus, the additional life-cycle costs

are determined by the basic parameters

of UAV and conditions of its

exploitation. Production costs in

general depend from method

adopted pre-production, the level

of cost per hour,

determined by conventional methods and

means.

4.

These dependences allow presenting

the process of choosing the tolerances

as a mathematical model and build the

algorithm and applied computer program.

References

1.

Íåãðåáà Â.À., Ôèðñîâ Â.À., Áîáðûêèí Þ.À. Òåõíîëîãè÷åñêèå îñíîâû

ïðîåêòèðîâàíèÿ êîíñòðóêöèé ñàìîëåòîâ. – Ì.: ÌÀÈ, 1986. – 43 ñ.

2. Êðàñíîâ Í.Ô., Çàõàð÷åíêî

Â.Ô., Êîøåâîé Â.Í. Îñíîâû àýðîäèíàìè÷åñêîãî ðàñ÷åòà. Òðåíèå è òåïëîïåðåäà÷à.

Óïðàâëåíèå îáòåêàíèåì ëåòàòåëüíûõ àïïàðàòîâ / Ïîä ðåä. Ïðîô. Í.Ô. Êðàñíîâà:

Ó÷åáíîå ïîñîáèå äëÿ ñòóäåíòîâ âòóçîâ. – Ì.: Âûñø. øê., 1984. – 264 ñ.

3. Ìåðîïðèÿòèÿ çàðóáåæíûõ

àâèàêîìïàíèé ïî ýêîíîìèè òîïëèâà / Òåõíè÷åñêàÿ èíôîðìàöèÿ ÖÀÃÈ, 1981. – ¹ 9. –

Ñ. 30-32.

4.

Âèãäîð÷èê Ñ.À. Òåõíîëîãè÷åñêèå îñíîâû ïðîåêòèðîâàíèÿ è êîíñòðóèðîâàíèÿ

ñàìîëåòîâ. ×àñòü 1. – Ì.: ÌÀÈ, 1974. – 140 ñ.

5.

Áîáðûêèí Þ.À., Íåãðåáà Â.À. Âûáîð òåõíîëîãè÷åñêèõ ðåøåíèé ñáîðî÷íîãî

ïðîèçâîäñòâà ñ èñïîëüçîâàíèåì ÝÂÌ. – Õàðüêîâ: Èçä. ÕÀÈ,

1980.- 64 ñ.

6.

Denis A. Coehlo, Filipe A.A. Corde. Technology

as a determinant of object shape. In book: Industrial design – new frontiers;

edited by Denis A. Coehlo. Crotia, 2011, pp. 15-32.

7.

Nickolay Zosimovych, Singla R.K. The analysis of tolerances criteria to UAV external

surfaces // “Ñîâðåìåííûå ïðîáëåìû è ïóòè èõ ðåøåíèÿ â íàóêå, òðàíñïîðòå,

ïðîèçâîäñòâå è îáðàçîâàíèè”. Ñáîðíèê íàó÷íûõ òðóäîâ SWorld ïî ìàòåðèàëàì ìåæäóíàðîäíîé íàó÷íî-ïðàêòè÷åñêîé

êîíôåðåíöèè/ Âûïóñê 4, Òîì 6. Îäåññà:

×åðíîìîðüå. – 2011. – Ñ. 26-35.

8.

Nickolay Zosimovych. The basic directions of improvement of quality the

UAV external surfaces. Materiały VII Międzynarodowej Naukowi-Practycznej Konferencji, 07-15 października 2011 roku. Przemyśl: Nauka I studia. – Vol. 16 Techniczne nauki. – 2011. Pp. 82-89.

9.

Zosimovych N.V., Singla R.K. Influence of factors determines the value

of tolerance on the outboard side unmanned aerial vehicles. Àâèàöèîííî-êîñìè÷åñêàÿ òåõíèêà è òåõíîëîãèÿ, Õàðüêîâ: ÕÀÈ, ¹ 3/90, 2012. – Ñ. 37-46.

10.

Ïðîáëåìû ñòðîèòåëüíîé ìåõàíèêè è ïðî÷íîñòè ËÀ: Òåì. ñáîðíèê íàó÷. òð. /

ÌÀÈ. – Ì.: ÌÀÈ, 1990. – 72 ñ.