Protsenko V.S., Vasil'eva E.A., Smenova I.V.,

Danilov F.I.

Ukrainian State University of Chemical Technology,

Dnepropetrovsk, Ukraine

Nano-structured Fe/ZrO2 composite

coatings electrodeposited from methanesulfonate electrolyte

The electrodeposition of iron, its alloys and

composites has been widely used for different engineering applications [1–4]. Iron-containing

deposits may be obtained from acidic sulfate, chloride, fluoroborate and

sulfamate Fe(II) electrolytes. Aqueous Fe(II) baths on the basis of methanesulfonic

acid (MSA) seem to be an attractive and perspective alternative to common iron

electroplating baths [5, 6] since MSA is considered as a "green acid"

due to its environmental advantages [7–10]. The performance parameters

of iron-based electrodeposits can be improved by the incorporation of dispersed

particles into metallic matrix [11, 12]. In the present work, the

electrodeposition of composite Fe/ZrO2 coatings has been

investigated using a methanesulfonate electrolyte.

Iron was

deposited from the bath containing 1.25 M Fe(CH3SO3)2.

The bath temperature was 298 K and the pH

value was 1.3. Doped zirconia nanopowder

ZrO2 + 3 mol% Y2O3 was applied for

obtaining composite iron-zirconia coatings. Mono-dispersed

nanopowders of stabilized zirconia contained particles with a prescribed size

of about 18 nm. Doping by 3 mol% Y2O3

was used for the purpose of stabilizing the tetragonal phase of zirconia.

It

should be observed that the iron coatings electrodeposited from the

methanesulfonate bath have a nano-crystalline structure, an average grain size

being about 40 nm.

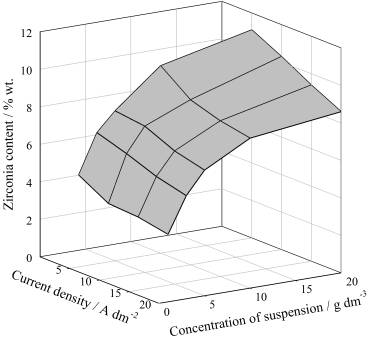

The

content of ZrO2 particles in the composite coatings increases with

an increase in the suspension concentration and decreases somewhat with an

increase in the cathodic current density (Figure 1). On the basis of analyzing the

experimental data, we have stated that

the mechanism of composite coatings formation in this work satisfactorily obeys

a kinetic model proposed by Guglielmi [13].

Figure 1. Effect of current

density and zirconia concentration in the bath on the ZrO2 content

in the composite coatings

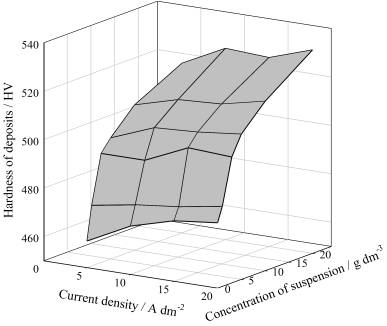

Figure

2 demonstrates that the introduction of

yttria-stabilized ZrO2 particles into the iron

matrix leads to an increase in the microhardness of the coatings. A growth in

suspension concentration results in an increase in the deposits hardness.

Figure 2. Effect of current density and zirconia concentration in the

bath on the deposits microhardness

We suppose that the enhanced hardness of composite Fe/ZrO2

coatings in comparison with pure iron is due to the dispersion strengthening

(i.e. strengthening effect by the

Orowan mechanism) [14, 15]. A dispersion strengthened composite is

characterized by a dispersion of fine particles which impede the motion of the

dislocations in metallic matrix resulting in an increase in material hardness.

References

1. S.L. Díaz, J.A. Calderón, O.E.

Barcia, O.R. Mattos, Electrochim. Acta 53 (2008) 7426.

2. N. Miyamoto, K. Yoshida, M. Matsuoka, J. Tamaki, J. Electrochem.

Soc. 151 (2004) C645.

3. F.I. Danilov, V.S. Protsenko, A.V. Ubiikon', Russ. J. Electrochem. 41 (2005) 1282.

4. P. Fu, C. Zhao, H. Tian, Adv. Mater. Res. 183-185

(2011) 1539.

5. E.D. Pleshka, Surf. Eng. Appl. Electrochem. 44

(2008) 92.

6. E.D. Pleshka, Surf. Eng.

Appl. Electrochem. 44 (2008) 264.

7. M.D. Gernon, M. Wu,

T. Buszta, P. Janney, Green Chem. 1 (1999) 127.

8. F.I. Danilov, T.E. Butyrina, V.S. Protsenko, E.A.

Vasil'eva, Russ. J. Appl. Chem. 83 (2010) 752.

9. F.I. Danilov, E.A. Vasil'eva, T.E. Butyrina, V.S. Protsenko, Prot. Met.

Phys. Chem. Surf. 46 (2010) 697.

10. F.I. Danilov, V.S. Protsenko, E.A. Vasil'eva, O.S. Kabat, Trans.

Inst. Metal Finish. 89 (2011) 151.

11. C.T.J. Low, R.G.A. Wills, F.C. Walsh, Surf.

Coat. Technol. 201 (2006) 371.

12. P. Zhou, Y. Zhong, H. Wang,

L. Fan, L. Dong, F. Li, Q. Long, T. Zheng, Electrochim. Acta 111 (2013) 126.

13. N. Guglielmi, J. Electrochem. Soc. 119 (1972) 1009.

14. W. Wang, F.-Y. Hou, H. Wang, H.-T. Guo, Scripta

Mater. 53 (2005) 613.

15. S. Mohajeri, A. Dolati, Mater. Chem. Phys.

129 (2011) 746.