Assoc.

Prof.

V.Yu. Ovsyannikov, graduate Ya.I. Kondrateva,

graduate student T.S. Kirichenko

Features

of concentration kinetics by freezing fruit juice

Sustainable

functioning and development of the food industry represents a significant

strengthening of the competitive potential of the industry is impossible

without a radical technical re-equipment and improving the quality of products.

In connection with

the foregoing, the actual seen the problem of obtaining high quality food with

minimum cost, which is impossible without deep study of the nature and

characteristics of the energy impact of processed agricultural commodities [1,

2].

As the

object of study of the concentration process by freezing was used cherry juice.

The

study of the change in the average amount of freeze-out ice from a unit of the

heat exchange surface, the freezing installation in time and the amount of

soluble solids, obtained experimentally, is one of the main characteristics of

the process of freezing moisture.

In order to study

the kinetic regularities of the process of concentration of cherry juice by

freezing, an experimental setup based on an ice maker «blexmatic

V41 electronic» [3].

During the

experimental studies, the following test procedure was used.

After

the external inspection of the unit, the chiller is turned on, the refrigerant

supply valve opens into the evaporator pins and the boiling point of the

refrigerant is controlled with a thermocouple. After reaching the required

evaporator temperature, the product was supplied to a bath in a horizontal

position and a stopwatch.

In the

course of the experiment, the evaporator boiling point, the suction and

discharge pressure of the compressor, and the duration of the freeze cycle were

recorded. At the same time, the voltage and current were measured in the motor

circuit of the plant.

After

the expiration of the freeze cycle, the bath was turned to the

"turned" position and the operation of the refrigeration unit was

switched to the "thawing" mode.

After

the freeze cycle, the capacity of the frozen ice plant and the solids content

of the concentrated product were determined.

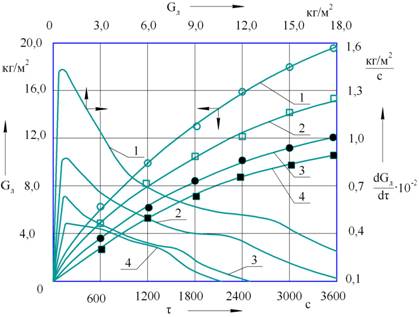

The

conducted studies of the growth and growth rate of the ice phase on the surface

of heat exchange elements with an area of

The thermo

physical essence of heat exchange processes is that the heat exchange surface

takes away heat from the freezing medium, and heat is partially transferred

during the crystallization of water into ice, and partly transferred in a

liquid medium as a result of thermal conductivity. Diffusion processes occur: moisture

on the contact surface with the heat exchange surface passes into the solid

phase, and moisture migrates to the more concentrated layer from the inner

layers of the medium.

Fig.

1. Curves of growth and growth rate of the ice phase on the

surface of heat exchange elements with an area of

Fig. 2. Dependence of the dry matter content in

the solution obtained during the melting of the

freeze-dried ice, S,%, with the consumption of

the initial product Q = 2·10-5 m3/s and the initial

dry matter content in the product of 12.4% of

the boiling point of the refrigerant in the

evaporator T0 , K and the specific

surface area of the heat exchange elements f, m2/m3

Analysis of the

obtained experimental ice-growth curves and the ice-phase growth rate curves

obtained by the method of graphical differentiation allow us to draw the

following conclusions.

An increase in the

initial dry matter content in cherry juice at a constant boiling point of the

refrigerant in the evaporator of the freezing plant nonlinearly reduces the

specific amount of ice formed on the heat exchange surface.

The boiling point of

the refrigerant in the trunnions of the freezing

installation also affects the specific amount of ice that has been frozen at

appropriate intervals during the organization of the process in the specified

time interval. A change in the boiling point of the refrigerant also causes a

nonlinear increase in the specific amount of ice that has been freeze on the

heat exchange surface, while the specific amount of freezing ice increases with

a decrease in the boiling point of the refrigerant.

Analyzing the dependence

of the solids content in the solution obtained from melting frozen ice from the

boiling point of the refrigerant in the evaporator of the ice maker (Fig. 2),

it should be noted that a decrease in the boiling point of the refrigerant

causes a monotonically nonlinear increase in the content of solids discharged

from the frozen ice, which may be Is explained by the appearance of quasistationary conditions for the formation of the crystal

structure of ice with capture of a part of the liquid phase and violation of

the conditions for diffusion "rejection" with xux

substances juice from the solidification front at a substantial temperature

difference values [4, 5].

The carried out

researches allow to reveal more deeply features and the mechanism of formation

of ice on a heat exchange surface of a freezing installation at concentration

of cherry juice.

Literature

1. Ovsyannikov V.Yu.

Concentration of the plasma of the blood of large livestock by freezing. Meat

industry. 2013. № 7. pp. 47-49.

2. Antipov S.T., Ovsyannikov V.Yu., Kondratyeva Ya.I. Kinetics of the

process of concentration by freezing cherry juice. Bulletin of the

3. Ovsyannikov V.Yu.,

Bostynets N.I., Denezhnaya A.N., Kraminova Yu.S. Thermophysical special features of freezing food media.

International student scientific bulletin.

2015. № 3-1. pp. 69.

4. Ovsyannikov V.Yu., Kondratyeva Ya.I., Bostynets N.I., Denezhnaya A.N. Investigation

of the process of freezing and thawing of fruit juices. Bulletin of the

5. Ovsyannikov V.Yu.,

Bostynets N.I., Denezhnaya A.N., Kondratyeva Ya.I. Control of the

process of low-temperature concentration of liquid media by freezing.

Automation. Modern technologies. 2016. № 2. pp. 10-13.