Êhaymuldinova Altyngul Kumashevna,

Bulasheva Aigul Imangalievna, Eszhanov Galihan Serdalinovich

Kokshetau State Universitynamed after Sh.Ualihanov,

str. Kuanyshev 170 (a), Kokshetau 000020, Akmola region, The Republic of

Kazakhstan

Changes in the quality of the fat phase

biocomplex to increase the protective functions of the body, depending on the

length of the dispersion

Keywords: dispersing, linoleic,

linolenic and arachidonic pentatenovaya, biocomplex oxidation reagent, acid,

peroxide number

Summary

Scientifically based method of lightening the

whole blood of horses without the use of chemicals by dispersing its

biocomposition using physical methods of treatment, with a sufficiently high

biological value and using it in meat production.

The optimal technological

parameters of production biocomplex (temperature insertion of components,

selection and order of mixing, the dispersion (maximum dispersion and stability

biocomposition observed at τ = 7 min., Average adipose particles = 1.96 mm), the lack of

hydrolytic and oxidative processes in fat biocomplex (within 6-10 minutes of

acid and peroxide are not changed and remain within 1.10-1.15 and 0,021-0,023

level control; PUFAs are not destroyed).

1 Changes in the content of

polyunsaturated adipose acids

To address the question of

whether to use mechanical processing in the manufacture of biocomplex decisive

factor is the quality of the product. Therefore, it became necessary to study

changes in the adipose phase biocomplex depending on the length of dispersion.

As a control experiment, adopted pork meat.

In addition to the peroxide and acid number of

adipose quality can be characterized by changes in the content of

polyunsaturated adipose acids such as linoleic, linolenic and arachidonic, are

vital and least stable at various physical and chemical influences.

Data on the change in the content of conjugated

compounds and peroxide value and acid number of adipose particles, depending on the length of the dispersion are given in Tables 1 and

2.

Table -1 Change of acid and peroxide numbers of

adipose particles in the process of

dispersing

|

Indicators |

¹ experience |

Thetreatmenttime, min |

|||||

|

Contact role |

3 |

5 |

7 |

10 |

12 |

||

|

Àcidnumber |

1 |

1,15 |

1,15 |

1,18 |

1,18 |

1,17 |

1,19 |

|

2 |

1,10 |

1,10 |

1,12 |

1,12 |

1,10 |

1,10 |

|

|

|

3 |

1,13 |

1,13 |

1,12 |

1,12 |

1,12 |

1,12 |

|

Ì |

|

1,13 |

1,13 |

1,14 |

1,14 |

1,13 |

1,14 |

|

± m |

|

0,015 |

0,015 |

0,020 |

0,020 |

0,024 |

0,027 |

|

Peroxidenumber |

1 |

0,021 |

0,021 |

0,021 |

0,020 |

0,020 |

0,020 |

|

2 |

0,020 |

0,020 |

0,019 |

0,019 |

0,019 |

0,019 |

|

|

3 |

0,023 |

0,023 |

0,022 |

0,022 |

0,023 |

0,013 |

|

|

Ì |

|

0,021 |

0,021 |

0,021 |

0,020 |

0,021 |

0,018 |

|

± m |

|

0,0009 |

0,0009 |

0,0009 |

0,0009 |

0,0009 |

0,0009 |

Table 2 - Changes in the

content of compounds with conjugated double ties in the process of dispersing

|

PairedConnection |

¹ experience |

Thedispersiontime, min. |

|||||

|

Contact role |

3 |

5 |

7 |

10 |

12 |

||

|

ÕÑ |

1 |

0,810 |

0,805 |

0,810 |

0,810 |

0,810 |

0,810 |

|

2 |

0,782 |

0,780 |

0,783 |

0,782 |

0,783 |

0,783 |

|

|

3 |

0,811 |

0,810 |

0,812 |

0,810 |

0,810 |

0,811 |

|

|

Ì |

|

0,801 |

0,798 |

0,802 |

0,801 |

0,801 |

0,801 |

|

± m |

|

0,0095 |

0,0093 |

0,0093 |

0,0093 |

0,0090 |

0,0092 |

|

ÓÑ |

|

- |

- |

- |

- |

- |

- |

|

ZC |

|

- |

- |

- |

- |

- |

- |

|

UC |

1 |

0,0163 |

0,0165 |

0,0163 |

0,0165 |

0,0166 |

0,0166 |

|

2 |

0,0141 |

0,0142 |

0,0141 |

0,0140 |

0,0141 |

0,0141 |

|

|

3 |

0,0156 |

0,0155 |

0,0156 |

0,0155 |

0,0156 |

0,0156 |

|

|

Ì |

|

0,0153 |

0,0154 |

0,0153 |

0,0153 |

0,0154 |

0,0154 |

|

± m |

|

0,00065 |

0,00067 |

0,00065 |

0,00073 |

0,00073 |

0,00073 |

As seen from the results shown in Tables 1-2,

the amount of diene, triene, tetraene and pentaenoate with conjugated bonds

does not change the duration of machining. Thus, we can say that the

polyunsaturated fatty acids: linoleic, linolenic and pentanoicarachidonic in

the formation of the emulsion is not broken, therefore the quality and

nutritional value of the fat phase of the duration of mechanical stress is not

reduced.

Acid and peroxide values of adipose particles

in the dispersion process are not changed and remain at the level of control.

2 The study of lipid peroxidation depending on the

length of dispersion

It is known that in the

process of dispersing adipose particles with the help of mechanical impact possible physical

and chemical changes of the object, manifested in destructive rearrangements

and lipid peroxidation.

The purpose of this phase of

the study to explore the change in the rate of accumulation of hydroperoxides

are the primary products of adipose oxidation, chemiluminescence method. This

method and the relative simplicity allows to fix the presence of hydroperoxide

concentration of 10-7-10-8 mol / liter, whereas the sensitivity of a standard

method of 10-4-10-6 mol / liter. The rate of lipid peroxidation is determined

by many factors: the composition of the mixture, the presence of factors that

inhibit and catalyzing process speed, temperature, oxygen availability, and

other antioxidants. Injection biocomplex in the blood may have combined value

to adipose oxidation as it contains substances which are may both enhance and

inhibit lipid peroxidation.

Injection of the biocomplex broth,

melange and other additives, having a strong emulsifying action, can slow down

the process of lipid peroxidation. In connection with these studies have established

that the influence of mode of mechanical action on the rate of peroxidation of

lipids of the adipose phase biocomplex. For this were studied the rate of lipid

peroxidation and total antioxidant activity. Lipid peroxidation was studied as

a function of time for processing the samples biocomplex. Samples were

processed with a homogeniser for 1, 3, 5, 7, 9, 12 and 15 minutes. Comply with

the same composition, temperature biocomplex, as well as the intensity of the

elastic vibrations in the processing of a homogenizer.

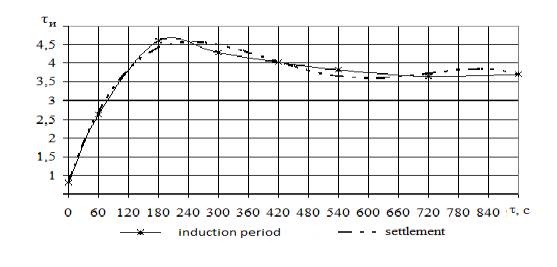

The data presented in Figure 1

demonstrate that increasing the duration of treatment, an increase of the

induction period, designated τ-period, indicating

that the increased antioxidant activity of the lipid. The increase in τ-period is biphasic: the first stage (up to 3

minutes), there is an increase it, and then a slight decrease (7 minutes). Such

a dependence of τ-period of the

duration of mechanical treatment may be a consequence of the opposite effects

on lipid peroxidation biocomplex components: blood and masses of

"Karty." On the one hand, the blood pigments - hemoglobin and its

derivatives containing heme iron are potent catalysts for the oxidation of

lipids; on the other hand - the presence in the membranes of red blood cells

tocopherol, having the properties of a strong antioxidant, inhibits lipid

peroxidation, formation of lepidopterology, lepidorhinusfraction. Formation and

lepidopterology

andlepidorhinusfractions ensures lightening whole blood. Presence of

biocomplex broth melange, sodium ascorbate and other additions leads to the

inhibition of lipid peroxidation, as it has a high antioxidant activity.

τè = 8·10-11

τ4 + 2·10-7 τ3 – 0,0001τ2 +0,0389 τ+ 0,8145 R2

= 0,98

Figure 1 - Change

in the injection period biocomplex depending on the length of machining

The antioxidant capacity of

the above additives due to their high emulsifying properties, providing a high

degree of dispersion of the fat phase biocomplex and building strong adsorption

lipodepsipeptide, lepidodendraceshells on the surface of the adipose particles,

preventing their coalescence. The presence of such layers not only provides

stability biocomplex, but also an important factor in inhibition of oxidative

processes in emulsified adipose particles. Furthermore, the antioxidant

properties of the broth and melange explained, firstly, their ability to bind

to divalent iron ions to form inactive in respect of the catalytic components;

Secondly, due to the presence within their structure of SH - OH groups can have

high antioxidant activity against lipid. This position is supported by the data

to determine the rate of lipid peroxidation by a TAC biocomplex.

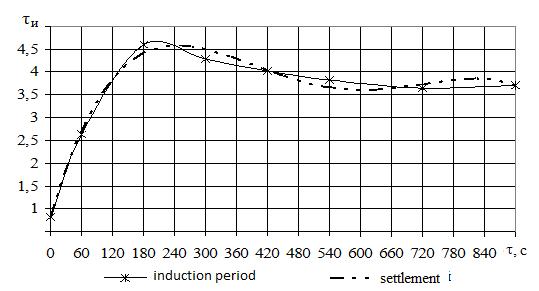

Figure 2 shows that with

increasing duration of mechanical treatment in the early stages there is some

increase and then a sharp decline in the accumulation of lipid peroxidation

products. This can be explained by the fact that the first is a free

non-emulsified adipose oxidation, the surface of which there is no layer of stabilizer.

With the increase in the dispersion stability and dispersion of biocomplex

increases, the amount of stabilized adipose phase increases, formed a strong

adsorption lipocarotene, leptophlebia, lepidosirenidaeshell that prevents

oxidation of lipids.![]()

ÒÁÊ= 3·10-11 τ4 + 7·10-8 τ3 - 5·10-5 τ2 + 0,013 τ +1,0554 R2=0,97

Figure 2 - Changes in titratable

acidity biocomplex protein depending on the length of machining

This result is confirmed by

the previously obtained data indicating that the most stable biocomplex with

minimum particle size of the adipose phase obtained by the processing time 7

min.

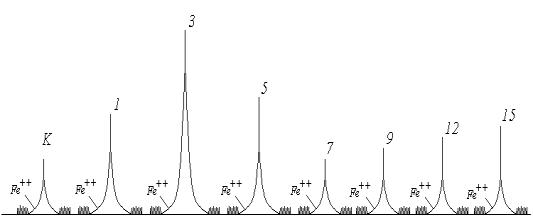

Change in the amplitude quick

flash chemiluminescenceaccording to the length of dispersion are shown in

Figure 3 Variation of the amplitude quick flash confirms the dependence of

lipid peroxidation on the degree of stability and dispersion biocomplex,

namely: first, the amplitude of the flash increases as the rate of formation of

hydroperoxides is higher than the rate of their destruction. However, with

increasing duration of treatment, behind a growing stability biocomplex, the

rate of formation of hydroperoxides decreases and reaches a minimum value at 7

min. processing. After a 7-minute treatment biocomplex stability is somewhat

reduced, which affects the rate of increase in lipid peroxidation, as evidenced

by the amplitude of the fast flash at 9, 12 and so on. G. Minute processing.

The increase in the rate of lipid peroxidation

in the initial period is due to the oxidation of free adipose, not more

involved in education biocomplex. In the second period the increase in the

dispersion leads to a complete structure formation system (maximum dispersion),

which is accompanied by the formation of shells around the adipose particles

and involvement in the regulation of lipid peroxidation antioxidants blood.

Figure 3 -

Variation of the amplitude quick flash chemiluminescence according to the

length of dispersion

Further increase in the length

of the machining reduces the dispersibility, a certain increase in the content

of free adipose particles and as a consequence, increase the rate of lipid

peroxidation and decrease of antioxidant activity.

We can say that the presence

in the mass of biocomplex "Karty" which is a structural antioxidant,

slows the formation of hydroperoxides, thus the quality of the adipose

particles phase in the dispersion process is not reduced.

Studies performed to study the

changes in the adipose particles phase in the manufacturing process biocomplex

revealed that the acid value and peroxide properties, as well as compounds with

conjugated double bonds when dispersed on the cutter during 1, 3, 5, 7 minutes

remained at the control sample. This indicates that no fine grinding increases

the rate of oxidation of adipose particles and destroys vital polyunsaturated

adipose acids such as linoleic, linolenic, arachidonic and eicosapentaenoate,

i.e. nutritional value of adipose particles in the dispersion process is not

changed.

Study of changes in the rate

of formation of hydroperoxides - primary products of fat oxidation -

chemiluminescence method showed that a slight increase in the rate of formation

of hydroperoxides at the beginning of the dispersion process due to oxidation

of emulsified adipose particles. With increasing dispersionbiocomplex increases

the amount of emulsified adipose particles and reduces the amount of

hydroperoxides. By 7 minutes dispersion rate of formation of hydroperoxides

reaches its minimum value. A slight increase in the amount ofhydroperoxides by

dispersing more than 7 minutes explained destruction biocomplex with the

release of free adiposeparticles.

This position is also

supported by the value of antioxidant activity, which is characterized by the

duration of the induction period and is in inverse proportion to the

relationship to lipid peroxidation. Changing the AOA and LPO depends on the

rate of formation of the fine system, which in turn depends on the emulsifying

ability of an emulsifier, such as broth, melange and nitrite.

Such a move depending on the rate of

increase of the duration of hydroperoxides dispersion due to the presence in

the composition of the above additives biocomplex with high emulsifying

capacity, which provides a strong adsorption membranes around the fat

particles, preventing the coalescence of fat particles as well as the contact

of the fat phase with oxygen in an aqueous medium.

Broth, egg and other additives

have been incorporated into the biocomplexare structural antioxidants,

inhibiting the rate of rise of hydroperoxides during the dispersion process.

Thus, the quality of the

adipose phase in the dispersion process using mechanical impact is not reduced,

ensures the formation of new biological complexes that increase the protective

functions of the organism.

Ñonclusion. Plural conclusions. Thus, from the above

literature data it can be concluded that in creating products for dietary food

the aim of achievement of their specific biological and nutritional value

through the efficient use of protein, adipose components of meat, raw milk in combination

with products of plant origin should be considered the main.

Acknowledgement: This article is based in order to create

products of high biological value. I am grateful to my research supervisor,

Doctor of Engineering, professor, corr-member of KazAAS of RK E. T. Tuleuov.

Corresponding

Author: Dr. Êhaymuldinova, Kokshetau State

University named after Sh.Ualihanov, str. Kuanysheva 170 (a),

Kokshetau 000020, Akmola region, Republic of Kazakhstan

References

1.

Sakata Ryoichi, Lee Guesong, Nagata YukihariNitrosation ofhemaglobin

from of meat products. //Nihon chikusangakkaiho. Anim.Sci and Technd-63, ¹

12.-1992. - S.1247-1252

2.

Potthast K., Europalsher 26. Fleischforscher – congress in Colorado

Springs USA // Fleischwirtschaft. – 1981. – Bd. 61, ¹ 5 - Ð. 749-772.

3.

Wiesmer – Pedersen J. Utilisation of animal blood in meat prodacts

//Food Technology. – 1979. – 33, ¹ 18 - Ð. 76-80.

4.

Boday C.R. Problems in the Development and Appllication of Rapid methods

of Assesing Protein Quality – Technology //J. Biol. Chem. – 1974. Vol. 31, ¹ 6

– Ð.73-77.

5.

Õîðîëüñêèé Â.Â.,

Ìèòàñåâà Ë.Ô., Ìàøåíöåâà Í.Ã., Áó÷èíñêàÿ À.Ã. Ìîëî÷íîêèñëûå ìèêðîîðãàíèçìû â

òåõíîëîãèè ìÿñíûõ ïðîäóêòîâ // Ìÿñíàÿ èíäóñòðèÿ. – Ì., 2006. - ¹ 5 - Ñ. 34-36.

6.

Boday C.R. Problems in the Development and Appllication of Rapid methods

of Assesing Protein Quality – Technology //J. Biol. Chem. – 1974. Vol. 31, ¹ 6

– Ð.73-77.

7.

21Brende J., Klein S. Der Einflure von Milcheiweremietsen auf das

WarberbindungesVercogen des lelsches //Vlelschesvirtschaft. 1972. – Bd. 52,3. –

Ð.339-340, Ð. 343-344.

8.

Sakata Ryoichi, Lee Guesong, Nagata YukihariNitrosationof hemaglobin from of meat products. //Nihon

chikusangakkaiho. Anim.Sci and Technd-63, ¹ 12.-1992. - S.1247-1252

9. EI Titov, Aleksakhina VA, VA Lisitsina, pollen LA,

Sershenko OI Blood sausage prophylactic administration. // Abstracts. II

International Workshop. Pyatigorsk, 1993. - C. 45-48.

10. Turkutyukov VB, Shimchik EA Blood spotted deer -

the raw material for foods for special purposes. // Abstracts. The inter.

nauch.konf. Vladivostok. 1993. - P. 56-59.

11. Antipova LV, SI Aslanov A new protein supplement

for combination products. // Meat prom. 1994, ¹ 4. - S. 23-25.

12. AV Antipov, Kulpina AL Using blood plasma for

industrial production of protein-containing animal products. // Meat Industry

2000, ¹ 8. - S. 5-12.

13. Pat. 5443852 proteinaceous food product comprising

a stabilized pigment heat-treated canned meat. / USA; appl. 04.30.93, opubl.22.08.95