Engineering science

1Liyasova O.V., 1Polishchuk

V.I.

1National Research Tomsk Polytechnic

University, Tomsk.

DEVELOPMENT OF SHORT CIRCUIT OF COILS PROTECTION OF SYNCHRONOUS

GENERATOR ROTOR WINDINGS

Introduction. The short-circuit of coils in synchronous generator’s rotor winding is

widely-spread [1] and hardly amenable to control disrepair [2]. In view of some

design features, standard based revealing of the short-circuit of coils in

rotor winding is an intractable problem. The most promising ways are based on

the analysis of the external and internal magnetic fields of the synchronous

generator since the correctly functioning synchronous generator has a sustained

symmetric shape of a magnetic field distribution in the air gap, in the core

and around it. This shape contains information connected directly and

functionally with the technical state of the synchronous generator.

Installation of the special magnetic field sensor is required in order to

conduct the control of short-circuit of coils in the rotor based on the

magnetic field symmetry analysis.

It should be noted that for relay protection issues

it’s significant to detect the space structure destruction distribution level

of magnetic field caused by the winding, not the level of magnetic field components,

i.e. requirement for current changes of pole’s fields figures detection relative to each other.

There is

certain number of devices [3-5] containing an induction sensor, which is

installed in the air gap near the rotor’s surface. Installed this way the

induction sensor gains its maximum sensitivity since the

short-circuit of coils is being defined by the EMF pulse amplitude which are

depend on the total current in every pole’s coil slot. However induction sensor

placement in the air gap or near it significantly reduces synchronous

generator’s reliability because of the possibility of its contact with rotor

which inevitably will lead to generator’s breakdown. The sensor installed on

the high-powered synchronous generators should be able to withstand great windy

loads under conditions of two atmospheres pressure and flow rate equals to

50-100 meters per second. Besides, this sensor could be easily damaged during

the rotor’s removal due to the repair.

Problem

statement. The mission was to gain the short-circuit of coils

signs in synchronous generator’s rotor winding and to develop the protection

based on the dispersion magnetic field sensor installed in the synchronous

generator’s end.

Experimental

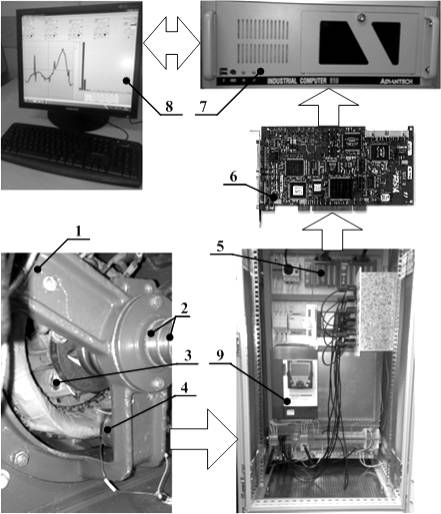

setup. The structure of the experimental setup is shown on fig.1.

Induction sensor was

used to measure the stray flux. It consist of the synchronous generator

with the pair number of poles p=1 (ÃÀÁ-4-T/230 generator model) 1, which is being actuated by the

nonsynchronous engine supplied by the frequency transformer (Altivar 71) 9. For

making a short-circuit sealing-offs (3) (4%, 10% and 30% of the pole’s coil)

are taken out through the additional contact rings (2) of the rotor’s winding.

The induction sensor

(4) is installed on the synchronous generator’s end bracket. The signal

goes through the input connector (CB-68LP) (5) and IO-board (NI PCI 6024E, 12

bytes, maximum sampling frequency – 20 MHz, 16 analog outputs) (6) are released

through the industrial computer (7).

Fig.

1. Experimental setup

Fig. 2 shows the EMF experimental waveforms on the induction sensor’s output

under the condition of short-circuit in one of the two synchronous

generator’s poles (for

display purposes short-circuit is 30% of all coils number) during the

open-circuit (Fig.2a) and under the load (Fig.2b). Curve 1 marks waveform in

case of the short-circuit of coils in rotor winding, curve 2 – without

it. According to the waveforms, during the short-circuit of one of the rotor’s

poles negative and positive EMF waveform are not symmetrical. They differ in

amplitude and shape. Therefore, difference of the positive and negative EMF

waveform on the induction

sensor output may serve as sign of the short-circuit of coils in rotor

winding.

a) b)

a) b)

Fig.

2. EMF waveform on the induction sensor’s output under short-circuit condition

in rotor’s winding pole.

a

– open-circuit mode; b –nominal load mode

Ways of

protection. Protection method is based on the

fact, that magnetic field induction in any point of the synchronous generator’s

end zone is formed by the stator’s and rotor’s winding currents, and

magnetomotive force of the all poles are equal in magnitude. During the full

rotor’s turn 2p equals in amplitude half-wave would appear when magnetomotive

force is converted in the unipolar electric signal. Magnetomotive force and

consequently magnetic field induction in the generator’s end zone would

decrease in the case of the short-circuit in one of the pole’s coils part. Then

at every full rotor’s turn one of the 2p half-waves would have smaller

magnitude in the unipolar signal. This would cause a harmonic wave with the ![]() where

where ![]() – is power frequency.

– is power frequency. ![]() magnitude is proportional to the

number of closed coils in rotor’s pole. If

magnitude is proportional to the

number of closed coils in rotor’s pole. If ![]() will exceed the established magnitude then a signal reporting about synchronous generator’s rotor winding damaging would appear. Or, in the

case of device functioning in the protection mode, would appear a signal

causing rotor’s field killing and generator’s disconnection.

will exceed the established magnitude then a signal reporting about synchronous generator’s rotor winding damaging would appear. Or, in the

case of device functioning in the protection mode, would appear a signal

causing rotor’s field killing and generator’s disconnection.

For the realization of method the device was

designed, structure of which is shown on the Fig. 2. The structures includes:

gage sensor; B1, B2 – are blocks of the unipolar signal shaping (rectifiers);

HPF – high-pass filter for the constant component suppression in the unipolar

signal; LPF1 – low-pass filter for the periodic component isolation by ![]() ; LPF2 – low-pass filter for the

input signal magnitude formation on Schmitt trigger; LPF3 – low-pass filter forming the

reference voltage (set point); NIST – non-inverting Schmitt

trigger.

; LPF2 – low-pass filter for the

input signal magnitude formation on Schmitt trigger; LPF3 – low-pass filter forming the

reference voltage (set point); NIST – non-inverting Schmitt

trigger.

In the case of

synchronous generator’s rotor winding damage induction sensor’s when proceed through B1 contains

desired signal in the form of the subharmonious frequency ![]() and also the pulsation frequency 2

and also the pulsation frequency 2![]() and the constant component, which are need to be suppressed. For

the Schmitt trigger correct functioning it’s necessary to compare the desired signal magnitude

with the induction

sensor’s signal magnitude. Constant post B1 component serves as the reference

voltage because it is proportional to induction sensor’s signal and by changing

amplification coefficient on LPF3 one can change setup’s magnitude.

and the constant component, which are need to be suppressed. For

the Schmitt trigger correct functioning it’s necessary to compare the desired signal magnitude

with the induction

sensor’s signal magnitude. Constant post B1 component serves as the reference

voltage because it is proportional to induction sensor’s signal and by changing

amplification coefficient on LPF3 one can change setup’s magnitude.

Isolation of

the subharmonious

frequency ![]() is made by the analog band-pass filter, which consists of HPF and

LPF1

is made by the analog band-pass filter, which consists of HPF and

LPF1

Fig. 3. Structure of the relay

protection device

Experimental testing. To except the multiple actuations

near the switch point, Schmitt trigger electric hysteresis magnitude is set on the 20% level.

To test the device settings it was given a test

signal. As it seen on the Fig. 4. Schmitt trigger actuates in parts II and IV which

represent short-circuit imitation of the 2% of coils. Delay of Schmitt trigger

actuation (about 2 cycles or 0.04 sec) is caused by the delay time in filters

functioning. Device itself functioned logically right.

Fig. 4. Device performance diagram

on the test signal example.

1 – post B1 test signal, 2 –

reference voltage, 3 – Schmitt trigger input voltage.

4 – Schmitt

trigger output voltage

After tuning by the test signal the device was tested

on the experimental synchronous generator. The device accurately detected of

short-circuit of coils in winding under the 4% pole’s coil short circuit.

Besides there were no fake actuation during power surge and drop modes,

initiation, non-symmetrical phases loading, earth fault in the one excitation circuit

point and earth fault of stator’s phase. Device actuation is restarted in

3-phase short-circuit mode on the outputs of synchronous generator, which

should be switched off immediately by its protection system. Introducing of the

time setup would except the fake performance of the developing protection.

Conclusion

1. The short-circuit of coils protection in synchronous

generator’s rotor winding causes the destruction of stray magnetic field

symmetry. Short-circuit can be detected by means of measuring and comparing the

level of stray magnetic field disorder

between the damaged and undamaged poles with the help of the special sensor.

2. EMF transformation in unipolar signal on the induction

sensor output with the following isolation of the subharmonious frequency equals the rotor’s turning

speed allows to detect the rotor’s short-circuit of coils.

3. As a result, during the experiments it was revealed

that developed device is able to detect the short-circuit of the 4% of coils in

in synchronous generator’s rotor winding.

References

1. Alekseev A.E., Kostenko M.P. Turbogenerators. – M:

Gosenergoizdat, 1939, - 341 p.

2.

Glebov I.A., Danilevic

JA.B. Diagnostic of turbogenerators. – L: the Science, 1989. – 119 p.

3.

How to diagnose and

control circuits in the rotor winding of synchronous machine: a stalemate.

2192649 dews. Federation. ¹ 2000129947/09; Appl. 30.11.2000; in English. 11 Nov

2002

4.

Jackson R.J., Roberts

I.A., Thurston R.C., Worsfold J.H. Generator rotor monitoring in the United

Kingdom//CIGRE. – 1986. Report 11-04, 8 p.

5.

Samorodov JU.N.

Turbogenerators. Accidents and incidents. – M: ELEKS-KM, 2008. – 488 p.

Abstract. The new method of short-circuit of coils protection in synchronous

generator’s rotor winding is based on the induction sensor of stray magnetic

field. The relay protection device is developed and researched on the

experimental setup, the methodology of this device tuning is defined.

Key words: the synchronous

generator, a rotor winding, short circuit of coils, relay protection.