Технические науки/5. Энергетика

Sadrtdinov A.R., Esmagilova L.M., Galeev Т.H.

Kazan National Research Technological University, Russian Federation

Effect of the preliminary thermo

treatment of a wood waste on gasification process

Environmental and social problems, energy security and fossil fuel

prices lead to increased research and development activities for renewable

bioenergy. This is especially important for biomass gasification technology,

which is actively developing over the last decade and has become the basis for

the production of synthesis gas (raw gas) that can be used directly or can be a

starting raw material in industry for the synthesis of various substances [1-3].

Effect of thermal

pre-treatment of raw materials (wood waste) on the quality of produced

synthesis gas has been studied in the development of the gasification process

improving. The

aim of study was to demonstrate that during the thermal treatment the waste

changes their properties showing more homogeneous appearance and enhancing of

the thermo physical properties [4-5].

Heat treatment of wood waste

is carried out at heating temperatures of 180 - 230 °C at atmospheric pressure

in the absence of oxygen, so that water and volatile components are removed

from waste wood.

The kinetic studies of the

wood waste heat treatment were carried out using thermo-gravimetric analyzer.

The emission, pollution and slags were also identified during gasification of

the treated waste. Calorific value of the syngas obtained from the treated wood

waste was carried out in specialized combustion chamber.

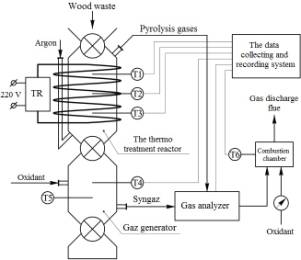

The experimental facility

scheme for comprehensive study of the wood waste thermo pre-treatment and

determination of the produced syngas quality was developed (Fig. 1).

The main unit of the scheme is a cylindrical reactor for the thermal

treatment of wood waste having a height of 500 mm and 100 mm in diameter, in

which for each experiment were placed 300 grams of the studied material. Inert gas, argon, was supplied to prevent combustion of

material in the reactor. Heating of the reactor and argon was carried out using

an electric tape with power of 4 kW. Reactor temperature was monitored at three

levels by thermocouples. Samples of the syngas were taken of at the outlet of

the reactor.

We studied the most frequently encountered wood waste (wood chips,

branches, etc.) which were analyzed as in the wet state as after heat treatment

for 30 minutes at temperatures of 180°C and 230°C, respectively [4].

|

|

|

|

Fig. 1 - Scheme of the

experimental facylity |

Fig. 2 - Changes in

carbon (C), hydrogen (H) and oxygen (O) contents in the studied materials. Elemental

analysis data. The O/C vs. the

H/C ratio |

The elemental composition changes of the wood waste after thermo

treatment processing are presented in Fig. 2. A

comparative analysis of the changes in the interrelations between carbon (C),

hydrogen (H) and oxygen (O) was carried out with each treated material using

charcoal as benchmark. All data was calculated (in mole percent) for the dry

and free from cinder part of the sample. Since the carbon in the wood is one of

the basic and significant weight elements we presented the results in the H/C

and O/C ratios, which was also allowed to construct a grid.

In the raw (wet) materials the O/C ratio varies in the range of 0.65 -

0.70, after the thermo treatment at 180°C its value is about 0.5 and after the

thermo treatment at 230°C the O/C ratio varies in the range of 0.3 - 0.4. This decreasing in the O/C ratio values is attributed to

the large removal of water and volatile substances with increasing of thermal

processing temperature, that leads to an increase in the relative amount of

carbon in treating material. According to the data obtained the studied thermal

treatment process is similar to the pyrolysis process, but proceeds at

relatively low temperatures with aim to optimally prepare wood waste for the

further gasification and syngas production with the desired quality.

As a result, oxygen

depletion determines a lower degree of oxidation and leads to an increase in

the heating value. The H/C and O/C values tend to rich value characteristic for

coal with heating, giving make assumptions about the similarity in the

properties of the treated materials and coal at gasification. Summarized data

also confirm that with increasing temperature of the treatment in addition to

removing of the volatile substances relative charring of material occurs.

Kinetics of devolatilization and charring at the thermal treatment was

determined by thermo gravimetric analysis.

|

|

|

Fig. 3 - Variations in the

composition of the syngas from the gasification of treated wood waste |

It is well known that the composition of the resultant syngas from coal gasification

is most clean and better quality [2]. With this data the best option for gasification

is wood waste treated at 230°C.

The experiments qualifying effect of the volatile processed from the

wood waste on the composition of produced syngas were carried out also. Results

of the treated waste gasification process represented in Fig. 3. The obtained dependences confirm the

legitimacy of the data presented in

Fig. 2.

Currently we are planning studies on the application of the produced

syngas as fuel gas for gas turbines and in the production of heat and

electricity.

The

presented materials are received during the realization of program for the

grant of the President of the Russian Federation under state support of young

Russian scientists. The cypher of the research topic is MK-3434.2015.8

"Development of theoretical foundations, technologies and equipment of

integrated thermochemical processing of waste wood and plant biomass into raw

materials for chemical synthesis and components of motor fuels".

References

1.

Tuntsev

D.V., Filippova F.M., Khismatov R.G., and Timerbaev N.F. 2014 Pyrolyzates:

Products of plant biomass fast pyrolysis. Russian Journal of Applied Chemistry, 87(9): 1367-1370. DOI: 10.1134/S1070427214090304.

2.

Timerbaev

N.F., Safin R.R., Safin R.G. and Ziatdinova D.F. 2014 Modeling of the process

of energy-technological treatment of wood waste by method of direct-flow

gasification Journal of Engineering and

Applied Sciences (EAAS) 9(5):

141-146.

3.

Tuntsev

D.V., Safin R.R., Hismatov R.G., Halitov R.A. and Petrov V.I. (2015, December)

The mathematical model of fast pyrolysis of wood waste. In 2015 Int. Conf. on Mechanical Engineering, Automation and Control

Systems (MEACS) pp 1-4. DOI: 10.1109/MEACS.2015.7414929.

4.

Safin

R.R., Khasanshin R.R., Shaikhutdinova A.R. and Safina A.V. 2014 Research of

heating rate while termo modification of wood World Applied Sciences Journal 30(11):

1618-1621. DOI:10.5829/idosi.wasj.2014.30.11.14223.

5.

Prosvirnikov D.B., Safin R.G., Ziatdinova D.F.,

Timerbaev N.F. and Lashkov V.A. 2016

Multifactorial modelling of high-temperature treatment of timber in the

saturated water steam medium. IOP

Conference Series: Materials Science and Engineering 124(1), 012088. IOP Publishing.

DOI:10.1088/1757-899X/124/1/012088.