Строительство

и архитектура / 3.Современные

технологии строительства, реконструкции и реставрации.

D. Egn., Prof. Golovko S.I., graduate

Shekhorkina N.E.

State Higher Educational

Establishment «Prydniprovs’ka State Academy of Civil Engineering and Architecture»,

Dnipropetrovsk, Ukraine

Injectability analysis of cement grout with different

water-cement ratio in fine sand

Abstract. Soil stabilization has become one

of the useful solutions to treat the soft soils to achieve the required

engineering properties and specification so that structures can be placed

safety without undergoing large settlements. Numerous of grouting materials are

available in this field now. Cement is the most popular grouting material where

the strength improvement of the formation materials is the major concern. Fine

sand is known to be not suitable for the application of cement based grouting. The

efficiency of grouting mainly depends upon the penetration of cement grout

through the pores of sand. Study of the grout injectability with different

water-cement ratio in fine sand was carried out in the present research work.

The results clearly indicated that water-cement ratio of grout has influence

only on mechanical characteristics of sand after strengthening but practically not

on the injection radius.

Key words: grouting,

grouting setup, cement grout, water-cement ratio, fine sand, injection radius,

void ratio.

Introduction. Grouting for ground engineering is

a process of filling the voids, fissures or cavities existing in the soil to improve

water-tightness or mechanical characteristics by the grouting material. The use

of grouting has become more popular in the recent years due to rapid

development of sub-surface infrastructure, underground facilities and

underground space for commercial and civil defense uses and the need in ground

control during construction.

Grouting can be used to improve the condition of site against possible

construction problems, such as: to reduce permeability of soil for minimizing

seepage effect, to strengthen soils for improving its load carrying capacity,

excavation stability and resistance against liquefaction effect, to improve

stability of existing structures and to adjust profile of distorted structures,

to stabilize ground for facilitating tunneling or shaft excavation, to form a

barrier or cutoff the water or contaminant flow in the ground.

Three types of grouting materials are generally recognized:

suspension-type grouts, emulsion-type grouts and solution-type grouts [4, 5]. The

suspension-type grouts include clay, cement and lime, while the emulsion-type

grouts include bitumen and the solution-type grouts include a wide variety of

chemicals. The type of grout material involved in the present study belongs to

the suspension type of grout. Suspension is defined as small particles of

solids which are distributed in a liquid dispersion medium, e.g. cement in

water, and having a Bingham’s fluid characteristics.

In accordance with theoretical investigations [2] it

was established that fine to medium sand cannot be strengthen by cement based

permeation grouting in view of its small pore size and low permeability to

water. But Cambefor A. found that sand ground is suitable for cement fracturing

grouting [2]. This fact was confirmed by numerous practical researches made by

Golovko S.I. [1]. He investigated the process of strengthening the sand by

high-pressure cementation.

Although it is a well known fact that properties of

grout have great influence on injection results. Even today grouting operations

are based on thumb rules and existing practices rather than design principles

and well defined procedures substantiated by research data.

Aim of research. In this paper an attempt is made

to study the injectability of cement grout with different water-cement ratio in

fine sand.

Results and discussions. Ordinary Portland Cement the

properties of which are shown in Table 1 was used for the present study. The

sand used for the present study was collected from the sand pit near the

Dnipropetrovsk. The sand was sieved through a set of sieves and the fraction

between 0.1 and 1 mm (fine sand) was used for the experiments. The grain sizes

of this sand are shown in Table 2.

The grouting efficiency can be estimated by determination the injection

radius and the volume of the hardened grouted samples.

In the present research grouting tests were conducted under vertical

flow model where grout was injected vertically downward through sandy media in

a cylindrical tank with uniform cross-sectional area under constant injection

pressure for measurement of flow volume.

Table 1

Cement Properties

|

Sl. No. |

Property |

Characteristic value |

|

1. |

Standard consistency |

27.5% |

|

2. |

Initial setting time |

131 mts |

|

3. |

Final setting time |

287 mts |

|

4. |

Specific gravity |

3.14 |

|

5. |

Specific surface (blane’s) |

298500 mm2/g |

|

6. |

Compressive strength 7 days |

24.53MPa |

Table 2

Sand Grain size

distribution

|

Characteristic value |

Sieve analysis |

Results of grain size distribution |

|||

|

Ground fraction, mm |

|||||

|

from 1 to 0,5 |

from 0,5 to 0,25 |

from 0,25 to 0,1 |

less then 0,1 |

||

|

Weight of

ground sample, g |

860,6 |

fine sand |

|||

|

Weight of

ground fraction, g |

7,32 |

142,14 |

687,48 |

23,66 |

|

|

Fraction loading, % |

0,85 |

16,52 |

79,88 |

2,75 |

|

The grouting setup consists of a grout chamber, membrane pump with pressure-gauge,

cylindrical ground tank, grouting nozzle and high-pressure hoses. General view

of grouting setup is shown in fig. 1.

The cylindrical ground tank of 500 mm in high and 500 mm in diameter had

a lower and an upper clamp covers. Dimensions of ground tank and grouting

nozzle were determined according to the similarity theory and dimensional

analysis [3]. Table 3 shows values of injection process parameters in nature

and in model where the scale parameter (λ) of 0.2.

Fig. 1. General

view of grouting setup: 1 – grout chamber; 2 – membrane pump; 3 – ground tank;

4, 5 – high-pressure hoses; 6, 9 – stopcock; 7 – pressure-gauge; 8 – grouting

nozzle;

10 – sand bed;

11 – perfectly elastic material; 12 – upper clamp cover.

Table 3

Parameters of

injection process

|

Parameters of cementation |

Value in nature |

Value in model (λ=0.2) |

|

Diameter of grouting

nozzle d, m |

0.093…0.127 |

0.02…0.025 |

|

Pressure of injection P, MPa |

0.5…1.5 |

0.22…0.67 |

|

Radius of injection r, m |

0.78…1.5 |

0.11…0.24 |

Sand bed was prepared at the loosest unit weight of 13.4 kN/m3

and the initial void ratio (emax) of 0.98. The layer of perfectly

elastic material was situated between the sand daylight and the upper clamp

covers and designed the stresses from the dead weight of sand in natural

conditions. If the sand average unit weight (γ) of 15 kN/m3 the

stresses from the sand dead weight (σzg) are 45 kPa at the

injection deep of 3 m. In accordance with this fact and compressive test the

level of perfectly elastic material must be higher than the wall of ground tank

of 8 mm for modeling the natural conditions. Grouting nozzle was situated in

the central part of ground tank. There are perforations in the middle of

grouting nozzle for the flat-radial filtration of solution.

The grout was suspension-type and consisted of cement and water. Grout

was prepared at water/cement ratio (W/C) of 0.5 and 1.0 and agitated well to

get uniform grout solution which was poured into the grout chamber. In order to

reduce the chances of the grout segregation, an agitator was provided in the

grout chamber. Grout volume for injection is 7 liters. Grout was pumped under a

uniform pressure of 4 atm into the prepared sand bed. During the process of

cementation spill water was released from the solution because of injection

pressure. There is an additional damping and therefore compaction of sand bed. The

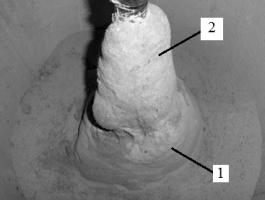

grouted samples were kept in the ground tank during 3 days for curing. General

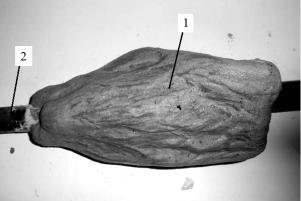

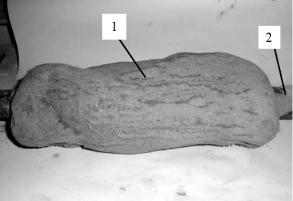

views of sand bed after cementation are presented in fig. 2. Typical

photographs of grouted sample are shown in fig. 3. Characteristics of grouted

samples are shown in table 4.

|

a) |

b) |

Fig. 2. General

view of sand bed after cementation: a – W/C=0.5; b – W/C=1.0;

1 – damping

zone; 2 – cement stone.

|

a) |

b) |

Fig. 3. Typical photographs of grouted samples: a – W/C=0.5; b – W/C=1.0;

1 – cement stone; 2 – grouting nozzle.

Table 4

Characteristics of grouted

samples

|

Characteristic value |

Grouted samples |

|

|

W/C=0.5 |

W/C=1.0 |

|

|

Diameter, mm |

150 |

120 |

|

Length, mm |

270 |

310 |

|

Density, g/cm3 |

2.064 |

2.191 |

|

Mass, g |

4150 |

3685 |

|

Volume, cm3 |

2010.66 |

1681.9 |

|

Compressive strength, MPa 3 days |

35.61 |

36.34 |

During injection there is a drilling grout loss of 3 liters in the

grouting setup. Therefore only 4 liters of grout were injected in sand bed. According

to the elementary mathematical analysis water absorbing is 2 liters for grout

with W/C=0.5 and 2.32 liters for grout with W/C=1.0.

It can be seen from the table 4 that application of grout with W/C=0.5

is more effective. Such grout causes the bigger injection radius and therefore

indicates better flow of the grout in the lateral direction.

Samples of ground from different depths were cut from the grouted mass

for the determination of soil dampness and consistency. Table 5 shows the

variation of sand bed properties with injection depths of 100, 200 and 400 mm

from the top of the grouted bed.

Table 5

Characteristics of grouted

sand bed

|

Depth of injection, mm |

Grouted sand bed |

|||||||

|

W/C=0.5 |

W/C=1.0 |

|||||||

|

ρ, g/cm3 |

ρd, g/cm3 |

W, % |

e |

ρ, g/cm3 |

ρd, g/cm3 |

W, % |

e |

|

|

100 |

1.548 |

1.458 |

6.2 |

0.82 |

1.681 |

1.594 |

5.5 |

0.66 |

|

200 |

1.598 |

1.501 |

6.5 |

0.76 |

1.651 |

1.542 |

7.1 |

0.72 |

|

400 |

1.597 |

1.531 |

4.3 |

0.73 |

1.59 |

1.513 |

5.1 |

0.75 |

There are better properties of sand bed for injection of grout with

W/C=1.0 because it has higher water content. But lesser values of consistency

and void ratio of sand bed after injection of grout with W/C=0.5 is compensated

by bigger injection radius.

Conclusions. The

efficiency of grouting mainly depends upon the penetration of cement grout

through the pores of sand. The following conclusions are drawn from the results

of injection radius determination on samples from the

grouted mass, in order to assess the quantum of grout lateral flow into the

sand soil. Cement grout with W/C=0.5 is more effective in fine sand compared to

grout with W/C=1.0, while considering the travel distance of the grout and the

properties of soil at various points in the grouted mass.

Thus, the present study undoubtedly proves the importance of

water-cement content selection in grout to achieve the largest injection radius

and effective strengthening of soil.

References

1.

Головко

С.И. Теория и практика усиления грунтовых оснований методом высоконапорной

цементации: Монография. / С.И. Головко. – Днепропетровск: Пороги, 2010. –

247 с.

2.

Камбефор

А. Инъекция грунтов. Принципы и методы / А. Камбефор; [пер. с фр.

Р.В.Казаковой, В.Б.Хейфица]. – М.: «Энергия», 1971. – 333 с.

3.

Седов

Л.И. Методы подобия и размерности в механике / Л.И. Седов – М.: Наука, 1977. –

440 с.

4. Beker W.H., Huck P.J. & Walter M.I. Design and control of chemical

grouting. Construction control / Beker W.H., Huck P.J. & Walter M.I. // –

Washington: DC, 1982. ‑ Vol.1. – 320 p.

5. Mitchell J.K. Soil improvement/ J.K. Mitchell // State of the Art

Report. ‑ Stockholm: Sweden, 1981. – P 509-565.