Infrared spectroscopy for

determination degradation of polymers

V. PETRÁnek1,

J. Kosíková2,

1

Brno University of Technology,

Faculty of Civil Engineering, Institute of Technology of Building Materials and

Components, Brno, Czech Republic, Tel.: +420 541 147 511, petranek.v@fce.vutbr.cz

2

Brno University of Technology,

Faculty of Civil Engineering, Institute of Technology of Building Materials and

Components, Brno, Czech Republic, Tel.: +420 541 147 521, kosikova.j@fce.vutbr.cz

1.

Abstract:

Infrared

spectroscopy method is very extended in various branches. The possibility of

using infrared spectroscopy in civil engineering is described in this paper. At

first, there is description of principals of infrared spectroscopy method,

preparation of samples and common utilization of IR. In the end of

paper the possibilities of determination of degradation of polymers by mentioned

method and as example the beginning of PVC degradation experiment is described.

The experiment is still in progress and will continue.

2. Introduction:

Infrared spectroscopy (Infra Red,

IR)

is one of the most significant analytic technologies – it is known since 1940,

however this technique became widespread and broadly used in

chemical-technological branches just in last 20 years because of availability

of more powerful computers. Also in building industry have IR spectroscopy

found its usage in few recent years.

The advantage of IR spectroscopy is the possibility to

study any type of a sample through liquids, solutions, pastes, powders, films,

fibres, gases and surfaces of different materials and also in little amount.

IR spectroscopy as physical technique of measurement is based on the interaction

between infrared thermal radiation with the studied matter.

Principle of IR spectroscopy:

Principle of measurement technique is in measuring of

absorbed IR radiation of different wavelengths, which passes through analyzed

material. It is based on vibrations of atoms in a molecule. The intensity

increases if the IR radiation is absorbed by the material. Each chemical bond

requires exact amount of energy to start to vibrate.

It is about electromagnetic radiation that occurs in

an area of wavelengths of 0.78 - 1 000 mm (it is 12 800 - 10 cm-1).

Generally we distinguish IR radiation among near (13 000 - 4 000cm-1),

middle (4 000 - 200 cm-1) and distant (200 - 10 cm-1).

Principle of the method depends on the absorption of IR radiation while passing

through the sample, during the absorption occur changes of vibration-rotation

energetic states of the

molecule in relation on changes of dipole moment of the molecule.

Fig 1: Electromagnetic spectrum

Analytical output is IR spectrum, which is graphical display

of functional dependence of the energy, often expressed in percentage of the

transmittance (T) or in units of absorbance (A) on the wavelength of incident

radiation. The transmittance is defined as the ratio of intensity of radiation

that passed through the sample (I) and the intensity of radiation emitted by

the source (Io). Absorbance is defined as the common logarithm 1/T. Wave number

is defined as inverted value of wavelength.

Preparation of samples:

As

I have already mentioned, this method can be used to measure samples in all

states of matter and in different modifications.

Liquid samples are being

measured as pure fluid or solutions. For the measurement we use liquid cuvette

consisting from two plan-parallel plates from NaCl or KBr. Also we can form

thin layer between two plates or we can use polymer porous carrier.

For measurement of

gaseous matter, special gaseous cuvette with front walls made from material

transmitting IR radiation, is used. The plates are in most cases made from NaCl

a KBr. Cuvettes are often 10cm long. We can also use so called „light pipe“

having small volume.

Samples

in solid form absorb IR radiation intensely so it is not so easy form from

these matters such thin layer that would transmit IR radiation. Because of this

we use these three techniques: KBr tablets – made from homogenized mixture of

the powder from the sample and KBr. Homogenization often takes place in special

vibrating mill, in steel homogenization capsule with little ball. Next the

mixture undergoes process of pressing, with maximal pressure of 80KN (in

vacuum) in steel bottom die under decreased pressure, into 0,5mm thick tablet.

This tablet is fastened into special holder and is installed into sampling

area. Because the fact that KBr is very hydroscopic, it has to be dried before

usage and the tablet is measured immediately after creation. KBr does not show

any absorption of middle IR area.

Nujols method – is suitable just for qualitative measurement. Nujol mixture is formed

by mixing of powder of a crushed sample and a drop of paraffin oil. This

mixture is prepared by attrition in agate bowl or among two straight vitreous

surfaces, which have to be sharpened till the last phase before polishing. IR

spectrums of suspensions are often very quality.

Films – develop after

mixing of sample with volatile dissolvent and deposition of this mixture on

NaCl plate. After evaporation of dissolvent reminds on the plate thin film,

that is carefully peeled away and is measured separately. This technique is

most suitable for polymers.

Common usage of IR

With the help of vibrating IR spectroscopy it is possible to study many

chemical and physical properties of samples. For example: changes in the

structure of molecules, isomerisation, polymerization, relative interaction of

molecules, chemical reactions, phase transition, dissolvent effect, adsorption

of molecules on the surface. This method is plentifully used in criminal

science for identification of toxic and addictive matters, in pharmaceutical

and in food processing industries. IR spectroscopy has special applications in

case of studying polymers. It is mainly about identification of polymer

material, about qualitative and also quantitative determination of its chemical

composition (stating final groups, branching of chains, configurations and

conformations and so on), also to determinate concentration of impurities,

antioxidants, additives and emulsifiers, softeners, fillings, and residual

monomers. With respect to slowness of processes it is also possible observe

such processes as vulcanization, polymerization or degradation. Last but not least it is as well possible to

study the influence of outer conditions on polymers (temperature and pressure,

radiation, deformation, influence of aging or humidity of surrounding environs)

such as on other building material.

For the measurement exist several types of

instruments, working on different principles, however the most significant area

of IR spectroscopy is usage of Fourier transformation. Spectrometers working on

a principle of this transformation have higher quality of spectrum and require

less time to get data.

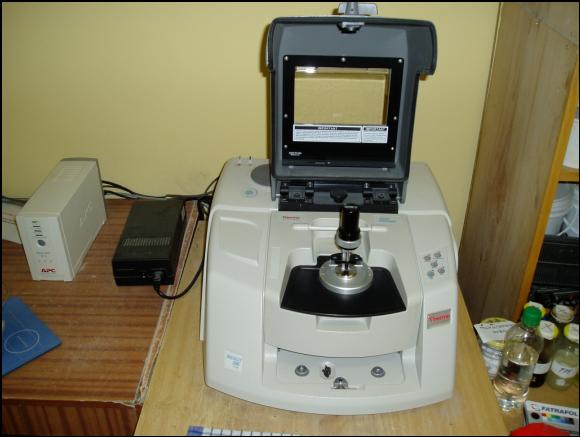

Fig. 2: Infrared spectometer working on principle

of Fourier transformation

As an example of usage IR spectroscopy in connection

with degradation of plastic matters, I would like to mention polyvinyl

chloride, which I concern as the most widespread plastic material in building

industry. By the method of IR spectroscopy were observed chemical changes

caused by the influence of UV radiation.

3. Determination of degradation of

polymers

As

a degradation of plastic matters we identify negative changes of their

properties or structure, which are caused by outer conditions and lead to

devaluation of material. There is a huge amount of outer conditions that

influences polymers in this way. The most common are high temperature, solar

radiation, water, humidity, biological agents, chemical activity and mechanical

charge. Main part of these conditions causes change of chemical structure of

polymers, which we can easily reveal by IR spectroscopy. For clearness I have

picked the case of degradation PVC under the influence of UV radiation.

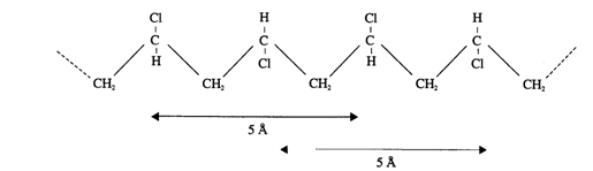

PVC

Polyvinyl chloride (PVC) is the most significant representative of vinyl polymer group.

Together with PE and PP is the most commonly produced synthesis polymer. The

reasons for the expansion of PVC are cheap production processes and important

properties. PVC is relatively very resistant to the influence of aggressive

agents and organic dissolvent with non-polar character, but it underlie thermal

degradation (even from 100°C) and degradation of light very easily.

Fig.3: Structure PVC – PVC contains 56% of chlorine.

It forms chains, which are partly direct and partly branched. Also presence of

few double bonds is supposed. The structure is often syndiotactic.

Its elaboration, on hard or softened material requires

additives of different matters, which can influence resistivity of final

material against atmospheric aging. Structure of additives and admixtures

differs, in case of different processors, in quality and also quantity

Degradation of PVC

The reason for investigation is eg. the fact that it

is used as roof hydro-isolation and sometimes the degradation of the material

is relatively very quick.

This method (nearly non-destructive) may even on the

small piece of material prove finishing persistence of the material.

If we focus on degradation caused by the solar radiation we talk about

photo degradation. The source of this radiation influencing degradation

processes is the Sun. Solar radiation acting on irradiated plastic may be by

its surface reflected, dispersed, transmitted or absorbed. This radiation cause

changes in appearance, extents, but mainly chemical changes, with which relate

changes of mechanical properties and so distinct decrease of practical

persistence of the material. Photochemical changes take place, only if solar

radiation of certain wavelength is absorbed.

Generally is true, that for example carbonyl group C=O

absorbs radiation with the wavelength 187 nm and in range of length from 280 nm

to 320 nm. Bond C-C absorbs radiation with the wavelength 195 nm and 230 nm up

to 250 nm. Plastics containing these groups, while being radiated by these

wavelengths, will induce photochemical reactions. By the absorption of solar

radiation will increase volume of energy of the molecule, which gets to the

higher energy state. The biggest part of absorbed energy is depleted for the

transmission of the electron system to the higher quantum state. The rest of

the energy is used for the formation of free radicals in macromolecules

indicating the decay of some plastics.

The main chemical reaction taking place during solar

radiation action but also because of other atmospheric factors is splitting of

hydrogen chloride from the macromolecule of polymer PVC.

Groups reactive within PVC are mainly atoms of

chloride and unsaturated bonds, which develop by the transmission of monomer,

by finishing of disproporcionations and last but not least during thermal

processes. The effect of aerial oxygen form carbonyl groups as well. PVC

belongs among polymers, which under the influence of temperature split of low

molecular products, so called destruct. The level of destruction is dependent

on the structure of polymer, on the intensity of radiation, on the wavelength

of radiation and on surrounding conditions. Destructive waste product is HCl,

which may in humid environment very intensely corrode the manufacturing

instruments. With progressing destruction, PVC turns through yellow, orange and

brown into black colour. In case of splitting of cca 4 % HCl it becomes insoluble.

We can identify double bonds and carbonyl groups mentioned above with the help

of IR spectroscopy.

4. Practical determination /

experimental measurement?

For the case of measurement with the help of IR

spectroscopy was used sample of roof hydro-isolation from PVC – Fatrafol 804.

For determination of influence of UV radiation on this material was used rapid

aging in apparatus Solarbox, where is in laboratory conditions solar radiation

substituted by UV radiation. The sample was exposed UV radiation in testing

apparatus Erichsen Solarbox 522/1500. As a source of UV radiation is there used

xenon lamp, wavelength of the apparatus was 550 nm. Output of the lamp is

800W/m2 and in the room is also higher temperature (app. 55°C). Duration of exposition of experimental sample

was 1000 hours. The sample was measured after 500 hours and after 1000hours

again, resulting spectra were compared with spectrum measured before the

experiment.

The apparatus on which the samples were measured is

Nicolet 380, which is easily serviceable and for upkeep undemanding ant it make

FTIR spectroscopy accessible to all routine users. The apparatus is controlled

by computer through software OMNIC. We use this apparatus in our development

laboratory also for measurement of samples of our clients.

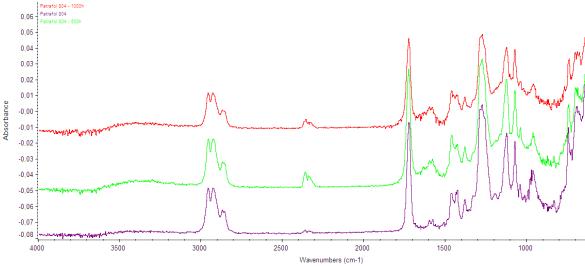

Comparison of spectrums is evident from the next

figure. The experiment is still running and samples are with respect to

non-destructive character exposed to UV radiation and regularly tested after

500 hours.

Fig. 4.: Spektrum PVC - before experiment, afther 500 and 1000hod in Solarbox

From this figure is evident, that there

are not observed any changes in chemical structure so I consider that after

1000 hours degradation of this hydro-isolation does not take place. Belts from

2950 to 2930 cm-1 are elastic bonds -CH2, belts 1725cm-1

are C═O bonds. Peaks 2360cm-1 are peaks of aerial CO2 and

they develop under the influence of environment in the laboratory, in the

surrounding area of 1100 – 1030cm-1 occur bonds Cl-C. In case that we want prove that this

material degrade, we have to choose probably much longer duration of UV

radiation exposition.

5. Conclusion

Finally we can say that the method of IR spectroscopy, working on the principle

of measuring of absorbed electromagnetic radiation by the material is suitable

for measurements in all physical states. It is very easy and quick method and

so that is why it is used in different fields of specialization, for example:

criminal science, pharmaceutical and food processing industries and in last 20

years it becomes important also in building industry. It is very convenient in studying chemical structure and

for determination of concentration of impurities, additives and emulsifiers,

softeners, fillings, and residual monomers. We can also observe with the help

of IR spectroscopy such processes as vulcanization and polymerization. Last but not least it is as well possible to

study the influence of outer conditions on polymers and degradation of material

caused by these conditions.

This method of IR spectroscopy was applied

to study degradation of roof hydro-isolation film made from PVC, caused by the

influence of UV radiation. With respect to intensity of radiation in Solarbox

was supposed that material will reveal HCl. By temporary measurement made on

samples was discovered, that even after 1000 hours of irradiation by UV

radiation in Solarbox, the material stays unchanged. This material is still

being exposed to radiation and we regularly test its chemical changes.

6. Acknowledgment

This

paper was prepared with financial support from the research project CEZ - MSM

0021630511, entitled: “Progressive Building Materials with Utilization of

Secondary Raw Materials and their Impact on Structures Durability”.