Assoc.

Prof. V.Yu. Ovsyannikov, graduate

student A.A. Avilov

Study

of main regularities of reproduction of bakery yeast

The study of the physiology

and biochemistry of yeast in the interests of their industrial use is fraught

with great possibilities. It is thanks to the use of the biological potential

of yeast that the achievements of the last decade in the field of the

construction of yeast-producing devices and aeration systems were realized,

which enabled a sharp increase in the concentration of processed molasses,

increased biomass accumulation and the removal of products from production

equipment.

In the present work, the

patterns of reproduction of baker's yeast and their relationship to the

accumulation and release of biomass have been studied.

The yeast multiplication was

studied in three main stages: anaerobic, weak aerobic and aerobic cultivation.

The cultivation cycle began with an anaerobic or slightly anaerobic stage. The

initial sequence was followed by three successive stages of aerobic yeast

growth. The initial stage was carried out in a high medium layer without mixing

(partial anaerobiosis) or with a weak periodic or

continuous aeration of the medium. The duration of the stage is 12 hours.

Cultivation in aerobic stages was conducted under the same conditions on a

laboratory installation by an air-supply method using a 10-hour regimen.

The nutrient medium in all

experiments was molasses wort, clarified by the

acid-hot method for the initial stage and by the acid-cold method for all

aerobic stages. Ammonium sulfate and diammonium

phosphate were used as sources of nitrogen and phosphorus, the pH during the

growing process was regulated with ammonia. The culture temperature was 30 ° C.

Studies

were carried out with the yeast of the Saccharomyces cerevisiae race used in industry. The seeding material

for the first stage was yeast from malt wort after 24

hours of cultivation at

At all

stages of cultivation, samples were regularly taken to determine the

accumulation of biomass, counting the total number and number of budding cells.

The final yield of biomass at each stage was expressed as a percentage of the

molasses consumed. Based on the accumulation of biomass, for each stage, the

average specific growth rate μ, g./h, the number of generations n, pcs, and the mean duration of generation q, h, were

calculated for the following formulas:

; (1)

; (1)

![]() ; (2)

; (2)

![]() , (3)

, (3)

where m0 - amount of seed yeast,

gr. (25 % dry matter); m1- amount of yeast at the end of the stage, gr.; t1 – t2 – duration of the stage, h.

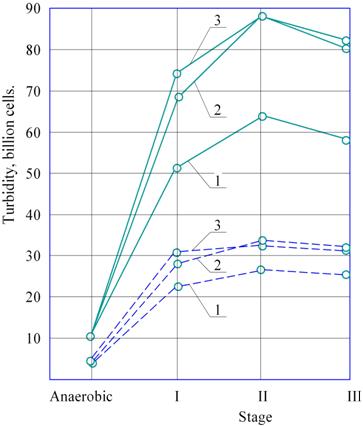

In Fig.

1 shows the dynamics of accumulation and release of biomass in four consecutive

stages of cultivation, where the initial was the anaerobic stage. The obtained

data indicate that the accumulation and yield of biomass in conditions of

partial anaerobiosis are low. These indicators

increase sharply in the first aerobic stage and continue to increase in the

second, but in the third stage, the accumulation and yield are reduced.

Accumulation and yield of biomass decrease with long-stored molasses and yeast

(curve 1), they increase when fresh molasses and a newly isolated yeast strain

(curve 2) are used. After the transition to a continuous supply of carbohydrate

nutrition in comparison with the batch feed in the first two cases, the biomass

accumulation and yield increased again (curve 3), however, the established

dynamics of their growth at different stages persisted. In an optimal variant,

the yield by stages (average data from six experiments) was 9, 74, 85 and 80%,

respectively.

Fig. 1. Change in the accumulation

and yield of biomass in yeast growing:

–––– exit, %; – – – accumulation of

biomass, gr.

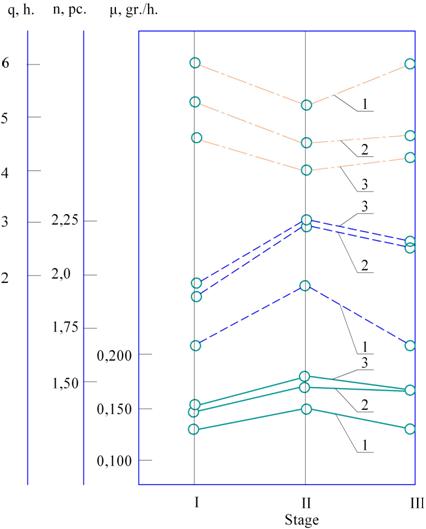

The

accumulation and yield of biomass in the aerobic stages varied in accordance

with the growth rate of yeast (Fig. 2). Simultaneously, the number of

generations changed, in inverse relationship - the generation time.

Thus,

the intensity of yeast multiplication is different in three consecutive stages

of aerobic growth, which are the same in terms of nutrition and aeration. After

the stage providing the maximum accumulation and yield of biomass, the further

multiplication of yeast proceeds less intensively.

Fig. 2. Change in the average

specific growth rate, generation number and generation time of yeast in

successive aerobic stages:

1 - using long stored molasses and

yeast strain; 2 - fresh molasses and a newly excreted strain of yeast; 3 - the

same in conditions of continuous supply of carbohydrate nutrition;

––––– biomass

growth module; – – – number of

generations; – · – · – duration of generation

n yeast, there is a

period of decline in biosynthetic abilities, leading to a decrease in the

accumulation and release of biomass. It follows from Fig. 1 and 2, this pattern

clearly manifests itself at different levels of the biosynthetic capacity of

yeast. The reason for this phenomenon is a change in the metabolism of yeast at

these stages of development.

It should be noted

that, despite the absence of clear indications in the scientific literature of

this pattern, industrial technology is empirically constructed on this

principle, according to which the maximum multiplication and yield of yeast is

reached only in the last, commodity stage.