I.

Pronin*, I. Averin*, N. Kaneva, S. Siuleiman,

A.Karmanov*, L. Krasteva, A. Bojinova, K. Papazova, D. Dimitrov, S. Igoshina*

Laboratory of Nanoparticle Science and Technology,

Department of General and Inorganic Chemistry, Faculty of Chemistry and Pharmacy,

University of Sofia, Sofia 1164, Bulgaria

* Penza State University, Russia

Pharmaceutical drugs photodegradation by nanosized ZnO films

1.

Introduction

Nanostructured materials offer promising

opportunities for improved and tailored properties for application in

environmental catalysis due to their unique physicochemical properties, caused

by their nanosized dimensions and large surface/volume ratios.

Currently, ZnO semiconductor has stimulated

great research interest due to its unique optical and electrical properties

(nanolasers, piezoelectric nanogenerators, solar cells, gas sensors, good

stability, considerable application in photocatalytic reactions in the process

of elimination of water contaminants (dyes, pharmaceutical drugs). Several

works report the synthesis and high photocatalytic efficiencies of ZnO

nanoparticles, powders and colloids. But for water treatment applications, ZnO

thin films are preferred to avoid the separation of the catalyst after the

degradation process. Several works have been published in respect to

photocatalytic properties of ZnO thin films prepared by different methods - pulsed

laser deposition (PLD), chemical vapour deposition (CVD), magnetron sputtering and sol–gel. The sol–gel method has been

receiving high attention since it enables us to develop low-cost and simple

deposition procedure to obtain large area high quality ZnO films for

technological applications.

This paper describes kinetic studies on the

photocatalytic degradation of pharmaceutical drugs (Paracetamol and

Chloramphenicol) by ZnO thin films annealed at different temperatures. The

semiconductor photocatalysts are prepared vie sol-gel method using dip coating

technique. Microstructure, surface morphology and photocatalytic properties of

the nanostructure films are explored and discussed.

2.

Experimental

ZnO thin films were prepared by the sol-gel method

from zinc acetate dehydrate (≥99.5 %), 2-methoxyethanol (≥99.5%),

monoethanolamine (≥99.0%);

all of them from Fluka. Zinc acetate dehydrate was dissolved in a mixture

of 2-methoxyethanol and monoethanolamine. The mixture solution was stirred at 60

oC for 1 h to yield a clear and homogeneous solution. After the

solution was made 1 day at room temperature (23±2 oC), it was coated

on glass substrates (ca. 76 x 26 mm, from ISO-LAB (Germany)), using dip coating

technique (0.9 cm/min). Then

precursor thin films were heated at 80 °C for 15 min to remove the solvent and organic

residuals. The coating and heating process was repeated for 5 times. Then the

as-prepared thin films were inserted to a furnace and annealed in ambient

atmosphere at several temperatures from 100, 300 and 500 oC for 60

min.

Surface morphology

of the thin films deposited on glass substrate was measured by Scanning Electron

Microscopy (SEM, JSM-5510 (JEOL)). The crystallization behavior of the ZnO thin

films deposited was analyzed by X-ray diffractometer (XRD, Siemens D500 with

CuKα radiation within 2θ range 30-70 deg at a step of 0.05 deg

2θ and counting time 2 s/step). The average crystallite sizes were

estimated according to the Scherrer’s equation.

The pharmaceutical drugs – Paracetamol (C8H9NO2,

Actavis) and Chloramphenicol (C11H12Cl2N2O5,

Actavis), widely used products, were employed as a representative analgesic and

antibiotic to evaluate the photocatalytic activity of ZnO thin films. The

experiment was performed in a 150 ml glass reactor, equipped with magnetic stirrer (rotating speed ~ 500

rpm controlled by stroboscope) and UV-lamp (Sylvania BLB, 315-400 nm of

emission range, 18 W). The light power density at the sample position was 0,66

mW/cm2 as measured with Research Radiometer of Ealing Electro-optics,

Inc.). The distance between the sample and the high pressure mercury lamp was

15 cm. The mineralization of the PCA and CA solutions were measured at

intervals of 1h and the total irradiation time is 4 h by UV-VIS absorbance

spectroscopy (spectrophotometer Evolution 300 Thermo Scientific, wavelength range from 200 to 400 nm). The extent of

photocatalytic degradation could be evaluated by measuring the absorbance of

the solutions at 243 and 278 nm. The degradation efficiency of PCA and CA were

calculated using the equation:

Degradation%=(C0-C)/C0*100 = (A0-A)/A0*100 (1),

where C0 represents the initial concentration, Ct represents the

concentration after t min reaction, A0 represents the initial

absorbance, and At

represents the absorbance after t min

reaction of the Paracetamol and Chloramphenicol at the characteristic

absorption wavelength of 243 and 278 nm.

3.

Results and discussion

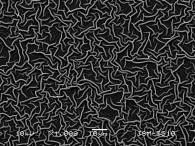

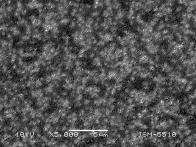

Figure 1a shows the surface morphology of ZnO thin

films annealed at 100 oC, with very smooth surface, covered by round

grains. Therefore, these

films have the lowest activity. The

sol-gel films, annealed at 500 oC, are more uniform

and show much

better adhesion of the layers

and the highest density of the film. There is ganglia

typical surface structure of the film. The surface morphology of the samples (Fig. 1b) is

represented by different ganglia-like

hills with typical width of about 1 μm

and a height of 5-10 μm.

(a)

(b)

Fig. 1. SEM images of ZnO thin films annealed at 100oC

(a) and 500oC (b).

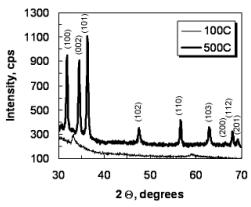

XRD patterns of the ZnO thin films are presented in

Fig. 2. The lack of three characteristic peaks of ZnO (Fig. 2a) shows that at

100 oC temperature the material is still in its hydroxide form of

rather amorphous state. The crystallite sizes estimated by the Sherrer,s

formula are about 30.0 nm. Increasing the

annealing temperature causes a transition from orthogonal in to hexagonal

structure, respectively from Zn(OH)2 toward ZnO. The diffraction

peaks of the sol-gel films (annealed at 500 oC, Fig. 2b) can be

indexed to (100), (002), (101), (102), (110), (103), (200), (112) and (201)

diffraction planes at 2θ = 31.77o,

34.42o, 36.25o, 47.54o, 56.60o,

62.86o, 66.37o, 67.96o and 69.09o,

respectively. The films produced are polycrystalline, showing the wurtzite ZnO

hexagonal structure, while there is no evidence for the presence of other

phases.

Fig. 2. XRD spectra of ZnO sol-gel films annealed at

100 and 500oC.

Photocatalytic tests are carried out for all the thin

films. Paracetamol and Chloramphenicol are used as a test contaminant. The

initial concentrations of the drugs are 15 and 8 ppm. The pH values

are observed during the photocatalytic reactions (PCA – 5.58

÷ 6.69 and CA – 5.31 ÷ 6.49).

Figure 3

demonstrate the bleaching kinetics of the PCA and CA in aqueous solutions by

ZnO films (annealed at 100, 300 and 500oC) under UV-light illumination.

It can be seen that the degradation efficiency of the thin films increases with

increasing annealing temperature. The experiments

show that the decolorization of PCA and CA under UV illumination follows pseudo

first-order kinetics expressed by ![]() . The slope of logarithmic scale represents linear fits of

the experimental data points by the equation.

. The slope of logarithmic scale represents linear fits of

the experimental data points by the equation.

The films annealed at 300 oC have higher

photocatalytic activity (PCA - k= 0.0081 min-1 and CA - k=

0.1024 min-1) than those, prepared at 100 oC (PCA - k=

0.0053 min-1 and CA - k= 0.0149 min-1). As seen

from the figure, the films obtained at 500 oC have the highest

photocatalytic activity (PCA - k= 0.0362 min-1 and CA - k=

0.1373 min-1). The values of the rate constants are confirmed by rate

of degradation of the pharmaceutical products. The degradation is calculated

using Eq.1.

Nanostructured ZnO films annealed at 500 oC have a highest photocatalytic efficiency (PCA -12.24% and

CA – 39.22% for four hours), while samples obtained at 100 oC

have a lowest activity (PCA -1.99% and CA – 5.88%),

Figure 3.

(a) (b)

Fig. 3. Photodegradation curves of Paracetamol (a) and

Chloramphenicol (b) using ZnO thin films as photocatalysts.

4. Conclusion

In summary, ZnO thin films are deposited by sol–gel

method using dip coating technique. The thin films consist of homogeneous and

ganglia-like structures belonging to hexagonal wurtzite structures. The

crystallites sizes are increased with rise of the annealing temperatures. The

enhanced photocatalytic activity of ZnO thin films might be ascribed to the

increase of surface to volume ratio, roughness and mean grain size. The good

performance of ZnO thin films indicates that it can be used as a promising

photocatalyst for the practical application in photocatalytic decolorization of

pharmaceutical products.

Acknowledgements: This research is financially supported by

projects BG051PO001-3.3.06-0050, FP7 project Beyond Everest and

Russian Presidential Program of engineer advanced trading.