Postgraduate

Kozhevnikova E.,

Doctor of Agricultural Science, Professor

Rebezov M.

South Ural State University

(National Research University), Russia

BUSINESS PROCESS DESCRIPTION OF

COORDINATION OF RECALL OF PRODUCTS WITH SPOILAGE SIGNS

One of the criteria of a successful work

of food retailing is quality products which reach the customer [1].

The modern interpretation of the quality

concept is as follows: "Product quality is a set of product features

determining its possibility to meet real

and potential needs". So the aim of the quality activity in retailing

is to provide the buyer with that level of service and products which the buyer

will consider as fair and corresponding with his costs [2].

Before you put the products on the shelf

you should make a pre-sale preparation and a grading of the products. Working

with defective products is of special importance and gives an estimation of the

company performance in whole [1].

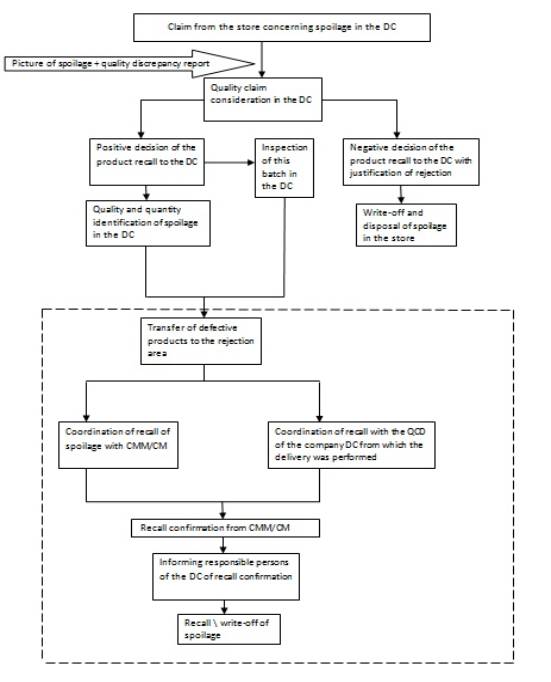

Let’s consider the procedure of

coordination of recall of products with spoilage signs in the company

Distribution Center (DC) (picture 1).

Picture 1 - Process of coordination of recall of products with spoilage signs with the company DC.

After

the procedure of recall of defective products from the store (the process

outside the dashed line) follows the process (marked with the dashed line) of

coordination of recall with the company DC directly.

Process

of coordination of recall of spoilage with the DC begins with informing

commercial marketing managers (CMM) or commercial management (CM) depending on

the fact from what store format a quality claim was received, in case that the

products had been received by the company DC directly from the supplier.

If

the products had been received from the Federal DC of the company the quality

claim is sent for coordination to the Quality Control Department (QCD) of the

DC from which the products were received.

A response

concerning coordination of recall with the DC or from CM/CMM should enter

within 24-72 hours. Then the QCD informs responsible persons of the DC where

the spoilage belongs to of the decision and the spoilage is prepared to the

recall according to the conditions specified in the bond of indemnity or in the

coordination which was received.

Literature

2.

Huber N., Kozhevnikova E, Kozhemyakina A., Telmanova E. Elaboration of measures

for quality assurance on retail trade enterprises // Muammahoy

peshrafti ustuvorii istehsoli mahsuloti huroka dar osiyoi markazi – Donishkadai politechniki donishgohi tehniki

Tochikiston ba noimi akademik M.Osimi // Problems of sustainable development of

food production in Central Asia : files of the international research and

practice conference. (31st of May – 1st of June 2013). -

Khujand: Osimi Tajik Technical University

2013. – P. 103-107