Kazakov V.A. Ph.D (in

technics), Vinogradov O.S. Ph.D. (in technics), Vinogradova N.A. Ph.D. (in technics).

Penza Region Centre of Higher

School (Branch) Russia State University of Innovative Technologies and

Business. Penza, Russia.

The problems of electrochemical productions automation

Covering

of metal coating different materials is done in electrochemical shops. The

process of coating by alloys is rather complicated meaning maintaining given

technological data. Such data considered to be temperature, currency` density,

concentration of components, acidity (pH) [1]. Changing

even of one of the components during the job's process might lead to a failure.

Nowadays,

control of the process is has been done periodically by the means of selection

of samples and temperature testing of mixture. Mentioned above control is

usually done not often than once in a shift- time. Rave control leads to

appearance of poor surfaces.

Usage

of automation for control and adjustment and technological process given an

opportunity not only to prevent defect but will let to realize during

production process coating super thin coverings with different alloys. But

realization these projects: coating plural-componential alloys with a given

exact component comes into collision with a problem of maintaining the

concentration initial substances in electrolyte. A solution to this problem

could be solved by a metered constant inputting a needed component into a

solution.

When

coating a surface change of quantity pH or a temperature leads to a change of

component's concentration in an alloy and sometimes to growing electricity

spending needed for the process

realization.

To

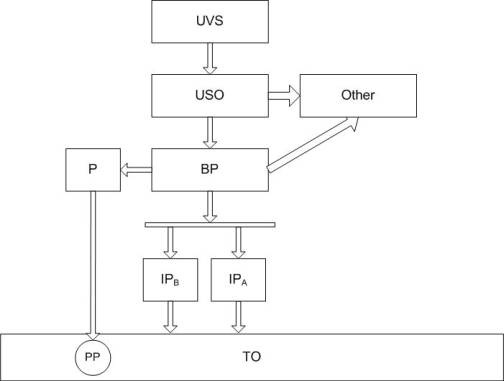

control the quantity pH different subsystem realization the following is

suggested (as at pic.1)

UVS- a universal

computing system

USO – a connecting

UVS device with an object

PP- an initial

transformer\ transmitter (gauge)

P- a transformer

IPa- a performing device for feeding a solution

Other – other

basins

TO- a technological

basin

BP- a shifting

device

Picture 1 – A

system of acidity in electrolysis basin scheme.

A

subsystem realizes a periodic control: compares electrolysis pH meaning de

facto to an optimal one, and also regulates pH electrolysis by input

concentrate solution acid and alkali into an electrolyses basin.

Supply

of acid and alkaline solutions is made by a performing device – a valve with

electromagnetic driving-gear.

Transformer

pH-261 is a device for transforming a

quantity electromotive force reader used for

measuring a pH quantity is analog signals of direct current (d/c) from 0 to 5

mA.

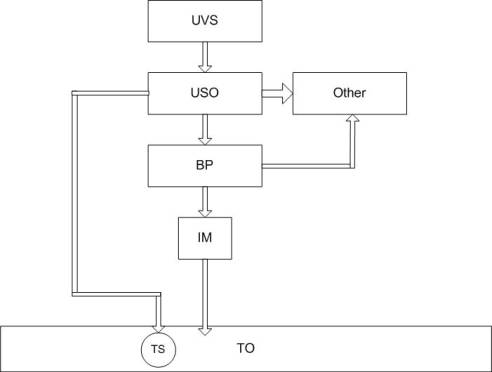

Temperature

maintaining subsystem is for centralized control and two-positioned discrete

regulation of electrolysis temperature in an electrolysis basin.

BP- a switching

device for controlled basins

IM- a performing

device

TS- a thermometer

of resistance

Picture 2 – Given a

scheme to it.

Subsystem realizes

periodic measuring of temperature current meanings compares it with admissible

deviations and regulated temperature by switching-in and off a performing

device. A performing device is for control and regulation temperature in

working basins and giving a signal of equipment readiness to work.

A performing

mechanism is a valve with an electromagnetic driving-gear.

When organizing

automated production it is necessary to program auto operator job which makes

transferring parts from position to another one, as if allows to save time of

process and minimize defect.

Usage of mentioned

above subsystems of automated control for feeding technological solutions components

and maintaining temperature of solution gives the possibility to improve

electrochemical production and put it into a better new level of development.

1. Vinogradov O.S.

Automation of electrolysis production Monograph [Avtomatizacia galivanicheckih proizvodstv]. Penza, Penza Branch of

Russia State University of Innovative Technologies and Business Publ.,

2012.162 p.