Технические науки/ 3.Отраслевое машиностроение

Dr., prof.

Zhetessova G.S., Ph.D.-student Telenkova E.A.

Karaganda State Technical University, Kazakhstan

Determination

of residual stresses in welds of metal powered supports

Welding stresses (temporary and residual) arise as a result of uneven

heating of the metal from a concentrated source of heat in the welded metal powered

supports.

Temporary welding stresses are active only during the welding when

temperature of the base metal changes. Stresses are called the residual welding stresses if they are stored in the

metal after welding, and complete cooling design [1].

Experimental studies were conducted to determine

the residual stresses in metal of powered support for the opportunity to control residual stress in the welding process

and increase the carrying capacity of powered supports.

Corner

weld bead of overlap powered supports 2OKP70K of were the object of study. The

number of samples was 10 pieces.

It was established experimentally that the material of samples was steel

14G2 (low alloy structural steel for weldments).

X-ray diffraction

studies were carried out using X-ray diffractometer DRON-2.

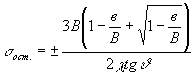

The quantity of residual stresses was determined by the line broadening

of diffraction pattern and Bragg angle according to the formula (1) [2]:

, (1)

, (1)

where В – half-width of the line broadening of diffraction

pattern of the standard

sample;

в – half-width of the line

broadening of diffraction pattern of the deformed sample;

χ – factor of the compressibility of metal;

ʋ - Bragg angle.

The standard sample was number 9, which was not subjected to welding

effect. Each sample was radiographed at three points at the root of the weld.

Substituting studied the quantity in formula (1), we obtained the

following residual stresses in the samples. Data were presented in the table.

Table - Residual welding stresses in the samples

|

Number of sample |

Number of point |

Residual welding stresses, MPa |

|

1 |

1.1 1.2 1.3 |

-0,135 -0,116 0,304 |

|

2 |

2.1 2.2 2.3 |

-0,486 -0,262 -0,584 |

|

3 |

3.1 3.2 3.3 |

-0,316 -0,560 -0,584 |

|

4 |

4.1 4.2 4.3 |

-0,314 0,162 -0,235 |

|

5 |

5.1 5.2 5.3 |

-0,584 -0,262 -0,748 |

|

6 |

6.1 6.2 6.3 |

-0,262 -0,568 -0,290 |

|

Number of sample |

Number of point |

Residual welding stresses, MPa |

|

7 |

7.1 7.2 7.3 |

-0,514 -0,249 -0,316 |

|

8 |

8.1 8.2 8.3 |

-0,584 -0,262 -0,514 |

|

9 |

9.1 |

0 |

|

10 |

10.1 10.2 10.3 |

-0,424 -0,316 -0,486 |

The sign of the stresses indicates that these were the compressive

stresses. These stresses have

arisen as a result of shrinkage during welding overlap of powered supports.

Also we noted that the quantity of residual welding stresses obtained

from the study, was close to the yield point of steel 14G2 (σt

= 320 MPa).

It is therefore necessary to use a local heat

treatment during the welding

process [3]. This does not remove all residual stresses, but reduces their

significantly.

Literature

1. Остаточные напряжения: Учебное пособие/

Ж.А. Мрочек, С.С. Макаревич, Л.М. Кожуро, М.Ф. Пашкевич, А.Ф. Ильющенко. – Мн.:

«Технопринт», 2003. – 352 с.

2. Жаркевич О.М. Определение показателей качества,

влияющих на

несущую способность механизированных крепей, с целью

повышения их срока службы// Магистерская диссертация. – Караганда: 2004, – 75

с.

3. Сагалевич В.М. Методы устранения

сварочных деформаций и напряжений. – М.: Машиностроение, 1974. – 248 c.