Òåõíè÷åñêèå íàóêè/2. Ìåõàíèêà

D.tech.scien. Artamonova E.N., Grigorieva E.V.

Saratov State Technical

University n.a. Gagarin Y.A., Russia

Modeling of destruction of polymeric materials

In this paper we propose a

mathematical model of destruction (the

relations connecting parameters of efficiency at the time of fracture

characteristics material), based on the relationship of both these approaches

to allow for the dependence of the limiting critical conditions at which the

destruction, the time of stress, temperature environmental exposure, exposure,

etc. This is especially typical for polymers [1]. An examination of these

experimental data one can draw conclusions that should be taken into account

when constructing the mathematical correlations for the conditions of fracture:

Mechanical properties and the process of destruction of polymer

materials substantially depend on time and operating conditions.

Destruction is a two-stage process. At the first stage the

degradation of the properties of the material, the accumulation of damage,

microcracks occur. The stage ends at a time when the merger of microdamage

formed macroscopic crack. This moment is short-lived and by their physical

nature is a loss of stability of equilibrium microdefects.

Because of the irreversibility

of the process of destruction is determined not only the current values of

parameters characterizing it, but the entire prior history change of these

parameters.

Because of the private nature of the experimental data on the

effect of medium on behavior of plastic the composition of the general

mathematical for all materials the

phenomenological description of fracture based on mechanical ideas due to the

difficulties and serious shortcomings. Therefore it is necessary and the molecular interpretation

of macroscopic changes in the material. Thus, the phenomenological theory of

time dependence as would provide a common framework, which must fit the theory

of material behavior, and that put a detailed mechanical theory of change of

macroscopic and microscopic properties of the polymer. This need arises in the

interpretation of the parameters of the phenomenological equation, allowing you

to identify not only the common features, as well as the difference between the

materials.

Because of significant time effects for polymers the process of

their destruction more difficult than traditional materials, the phenomenon of

viscous and brittle fracture occur simultaneously. Fracture criterion in this

case must take into account the achievement σ, ε of the instantaneous and

destructive values σ ð, ε ð, at

the time tðàçð., and their dependence on the

development of degradation of material properties ω (t).

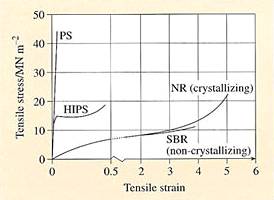

Figure 1.

Analysis of experimental data (Fig.1) suggests characteristics

of the temperature dependence of relaxation processes and fracture for

viscoelastic polymers with the same value of energy activation for each material.Both aspects of the strength of

polymers depend on the local structural changes that primarily can be linked

with the process of accumulation of damage, education grid hairline cracks.

Combining different approaches to describing these processes, i.e. formulation

of a general mathematical theory of deformation and fracture of polymers depends

on the study of the relationship of deformation, destruction and action of

strain, temperature, aggressive factors in the whole time interval of operation

of the element.

According the survey of the

literary sources for the analyzing of long-term durability of materials and

elements made of them two alternative approaches are basically exist:

mechanical (benchmarking) and kinetic.

According the first approach we

model the generalized condition for material destroying:

Ô (θ1, θ2, θ3 ) = Ô ð.

Here Ô - the functional is some combination of the components

of the stress or strain. The functional

Ô depends

on the accepted theory strength or given empirically and then the functional

contains parameters determined experimentally.

Ô = ∫dV [1/2 ρu iu i– λ/2 ∂ui/∂xi ∂uj/∂xj - µ/2( ∂ui/∂xj ∂ui/∂xj + ∂ui/∂xj ∂uj/∂xj)].

1.The strain tensor can be

represented as a sum of tensors of elastic deformation of inelastic

deformation:

ε ij = ε ij¹ + ε

ij².

2. For description the strain state and fracture in the framework of a

generalized model of inelasticity is necessary to consider the history of

deformation of the sample depends on the loading path and on time. For

different loading paths for the processes of varying duration results will be

different.We give a physical explanation of the above stated hypothesis.

References:

1. Suvorova J.V., Ohlson

N.G., Alexeeva S.I. An approach to the description of time-dependent materials

//Materials and Design, Vol.24. Issue 4, June 2003.- P.293-297.