Tåõíè÷åñêèå íàóêè/ 3. Îòðàñëåâîå

ìàøèíîñòðîåíèå

Banshidhar Choudhary1, Nickolay Zosimovych2

1Sharda University (Greater

Noida, India, UP)

2State University of

Telecommunications (Kyiv, Ukraine)

CONTACTING PARTICLES OF

HCM WITH A MONODISPERSE COMPONENT

In these article has been conducted a simulation of the

structure of heterogenous condensed mixtures containing one or two monodisperse

particles in a wide range of their volume concentrations. It was

determined the main statistical characteristics describing the internal

structure of HCM. It has been

shown that the method of viscous suspension allows simulating a appearance of regular structures when the volume concentration of the particles

is close to the maximum possible corresponding close packing.

Key

words: Heterogeneous condensed mixtures (HCM), viscous suspension,

monodisperse particles, correlation, concentration, coordination number,

combustion,

cluster,

distribution, simulation.

Introduction. The

problem of random spatial arrangement of solid spheres (or discs in the plane),

with a given diameter distribution is not only applied but also the fundamental

significance, as occurs in many areas of science [1-4].

The analytical

solution of this problem even in the simplest case is missing, so the primary

method of research is computer modeling. However, and in this case there is no

common method of placing in space particles with diameters of random given

distribution [5, 6]. Direct solution of this problem by sorting even for the

small number of particles occupies an unacceptable time and very often does not

lead to the final result. The main difficulty consists in the fact that the

allocation of particles should not overlap.

The

greatest difficulties arise when particles are placed in space with wide spectrum

of sizes. Methods mentioned above frequently lead to that of the size

distribution of particles which is different from the distribution of the

initial particles.

The structure of heterogeneous condensed

mixtures. The suggested by S.A. Rashkovsky method of viscous

suspension [7] may be applied to simulation of a structure having broad class

of composite materials which are filled with solid particles having almost

spherical form. The author has made a mathematical simulation of metal

containing and metal-free HCM structures by the method of viscous suspension.

In general, the system is characterized by volume concentrations of components equal to the ratio of the total volume of particles of a given type to the volume of the

entire system. Let us introduce

volume concentration of oxidizer particles ![]() and aluminum particles

and aluminum particles ![]() [8]. We also

chose solid and impenetratable walls as a boundary condition to make

computations.

[8]. We also

chose solid and impenetratable walls as a boundary condition to make

computations.

Calculations by the method viscous suspension

were carried out for a wide class of

HCM containing several types of dispersed components, each having its own function in the

distribution according to size. However, a system with particles of the same diameter already

has all the properties inherent in real HCM. What's more such

a simplification allows distracting from the complex analysis connected with the distribution of particle sizes [8].

HCM with a monodisperse component. Let us consider first a HCM structure, comprising monodisperse particles of the same type.

Such a system corresponds to the metal-free HCM, containing

a binding substance and a dispersed

oxidizer, such as AP. In this case, the simulation results describe the distribution of AP particles

in the volume of HCM.

At the same time, the system under consideration allows to simulate the distribution of the particles of aluminum in metal containing HCM, if aluminum particles are much smaller than particles of oxidizer. As we know [9, 10], when the system

consists of two kinds of particles which

sizes differ substantially, large particles can be

placed first in the volume, and then in the space between them - fine particles. The typical distance

between the large particles will be substantially larger than the diameter

of fine particles. It means that we can be distracted from the real structure of the system and treat the

distribution of fine particles between large ones as if fine particles were

distributed in the free space with an efficient volume concentration

(1)

(1)

In this case, the simulation results will describe the distribution of aluminum particles in the space between the AP particles (1).

Thus, in this study the volume concentration of particles ![]() will be

understood as

will be

understood as ![]() or

or ![]() depending from the simulated system. Accordingly all linear dimensions will

be referred either to the diameter of the AP particles

depending from the simulated system. Accordingly all linear dimensions will

be referred either to the diameter of the AP particles ![]() or to the diameter of

aluminum particles

or to the diameter of

aluminum particles ![]()

Many of the properties of HCM, especially acoustic and electromagnetic ones, are determined by the

arrangement of the particles of dispersed components.

The arrangement of the particles in HCM

determines scattering and quenching of

acoustic and electromagnetic waves in a material, just as the arrangement of atoms in

a solid body or liquid determines

the X-ray scattering [11].

The pair correlation function

is the most important characteristic of

the system, which describes arrangement of the particles.

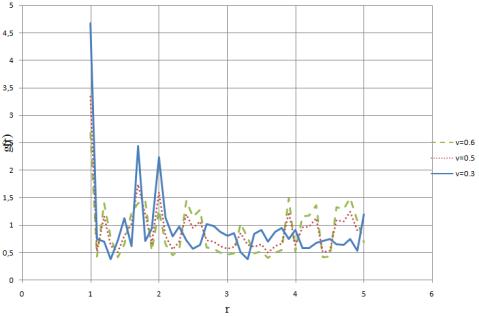

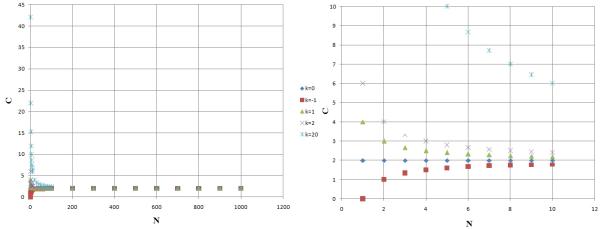

Fig. 1. The pair

correlation function of a system of identical hard spheres, obtained by the

method of viscous suspension ![]()

Fig. 1 represents the pair correlation function

of a system of identical hard spheres, obtained by the method of viscous

suspension for different volume concentrations of particles.

Calculations

demonstrate that for volume concentrations of particles ![]() the pair correlation function

has two maxima if

the pair correlation function

has two maxima if ![]() If

If ![]() the function

the function ![]() has a

has a ![]() shaped characteristic describing contact particles. The amplitude of this

shaped characteristic describing contact particles. The amplitude of this![]() shaped characteristic is determined by the probability

of particles' crossing each other when initially filling

the space. This probability id determined as

shaped characteristic is determined by the probability

of particles' crossing each other when initially filling

the space. This probability id determined as ![]() because at low

because at low ![]() initially crossing each other

particles build further pairs of contact particles. Both maxima at the distance

initially crossing each other

particles build further pairs of contact particles. Both maxima at the distance

![]() become apparent due to the

presence in the system of contact particles.

become apparent due to the

presence in the system of contact particles.

Fig. 1 shows that if ![]() particles are

randomly distributed in the volume because correlations decay very fast and

when

particles are

randomly distributed in the volume because correlations decay very fast and

when ![]() the

correlation function is close to unity. With the increase of

the

correlation function is close to unity. With the increase of ![]() the correlation length increases as well. In such a case change of the correlation

function has the character of

damped oscillations which fact indicates appearance and

growth of regular structures. When

the correlation length increases as well. In such a case change of the correlation

function has the character of

damped oscillations which fact indicates appearance and

growth of regular structures. When

![]() the correlation length reaches 10. This means that when

the correlation length reaches 10. This means that when ![]() there already exist quite large regular structures in HCM, in which location

of the particles close to the close packing (this is supported by studies conducted by

S.A. Rashkovsky, Moscow Institute of Heat Technology, Russia

Federation) [12]. Thus, at high

volume concentrations of particles of

dispersed components HCM forms regular structures of

sufficient extent within which the arrangement of the particles can not be

considered accidental. However, this is only true for monodisperse particles. For polydisperse particles

with a wide range occurrence of regular structures is observed at much higher volume concentrations in comparison to monodisperse ones or

they do not occur at all.

there already exist quite large regular structures in HCM, in which location

of the particles close to the close packing (this is supported by studies conducted by

S.A. Rashkovsky, Moscow Institute of Heat Technology, Russia

Federation) [12]. Thus, at high

volume concentrations of particles of

dispersed components HCM forms regular structures of

sufficient extent within which the arrangement of the particles can not be

considered accidental. However, this is only true for monodisperse particles. For polydisperse particles

with a wide range occurrence of regular structures is observed at much higher volume concentrations in comparison to monodisperse ones or

they do not occur at all.

It should be noted that the pair correlation

function obtained by method of viscous suspension is different from the pair

correlation function of "solid atoms" obtained by method of molecular

dynamics [11, 13, 14], and the presence of ![]() features when

features when ![]() and

and ![]() associated with a

finite probability of particle contacts in HCM. If we truncate the contact

particles that will correspond a uniform distribution of particles in the void

space (i.e., the centers of particles in the space between the particles

themselves), the standard pair correlation function coincides with the pair

correlation function for "solid atoms".

associated with a

finite probability of particle contacts in HCM. If we truncate the contact

particles that will correspond a uniform distribution of particles in the void

space (i.e., the centers of particles in the space between the particles

themselves), the standard pair correlation function coincides with the pair

correlation function for "solid atoms".

Another important characteristic of HCM is

the coordination number of particles - the number of contacts with neighboring

particles characterizing reactivity of HCM, and the ability of the aluminum

particles to agglomerate. It has been noticed that when![]() there is a large

number of particles which do not contact with any of the particles. In this

case, the maximum occurs in 1-2 contacts. And on the contrary, if

there is a large

number of particles which do not contact with any of the particles. In this

case, the maximum occurs in 1-2 contacts. And on the contrary, if ![]() the system has very little free particles which do not contact with other.

In such a case the maximum occurs in 5 contacts, and the system has a

significant number of particles simultaneously in contact with other 8-9

particles.

the system has very little free particles which do not contact with other.

In such a case the maximum occurs in 5 contacts, and the system has a

significant number of particles simultaneously in contact with other 8-9

particles.

Contacting particles in HCM form clusters [14].

When a heat wave passes through HCM aluminum particles in clusters fuse to form

a quite long structures. These structures play an important role during the

combustion process. First, they have higher thermal conductivity and during a

combustion process in HCM play a role of "thermal bridges"

transferring heat from the surface layers of HCM deep into ![]() phase. Second,

these clusters represent "germs" of agglomerates that are formed

during combustion of metallized HCM and change power characteristics of solid

fuel installations [15, 16]. All that points to the fact that clusters of

contacting particles are important elements of the HCM structure determining

the combustion process [17].

phase. Second,

these clusters represent "germs" of agglomerates that are formed

during combustion of metallized HCM and change power characteristics of solid

fuel installations [15, 16]. All that points to the fact that clusters of

contacting particles are important elements of the HCM structure determining

the combustion process [17].

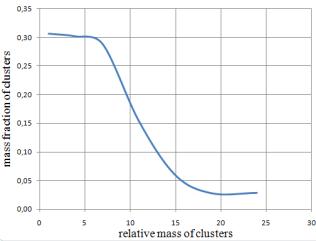

The function of distribution of clusters by weight is a

statistical characteristic of the cluster system.

For the HCM which is considered here and

contains particles of the same size it makes sense to talk about mass fraction of clusters formed by an exact number of![]() particles:

particles:  where

where ![]() is a number of clusters containing an exact number of particles,

is a number of clusters containing an exact number of particles, ![]() is a total number of particles in the

HCM. Obviously, here

is a total number of particles in the

HCM. Obviously, here

![]() is a relative mass of cluster (cluster

mass as respects to the mass of one

original particle).

is a relative mass of cluster (cluster

mass as respects to the mass of one

original particle).

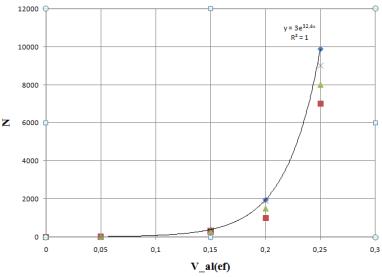

Fig. 2. Distribution of

clusters according to their mass in the system of similar hard spheres for different

volume concentrations of particles

Fig. 2 shows the distribution function of clusters

of contacting particles by weight (for the volume concentration

of particles 0.2) in HCM for relatively low weight of clusters (less than 30).

With the increase of the volume

concentration ![]() the fraction of clusters with low weight decreases, but the number of clusters with a large (and very large) weight increases.

the fraction of clusters with low weight decreases, but the number of clusters with a large (and very large) weight increases.

We simulated distribution function of clusters

of contact particles by weight for ![]() within the whole weight range. It is evident that the system has very large clusters containing more than 5,000 original particles. We analyzed the size of clusters occurring

at different volume concentrations

within the whole weight range. It is evident that the system has very large clusters containing more than 5,000 original particles. We analyzed the size of clusters occurring

at different volume concentrations![]() The clusters occurring

in the “sample” HCM at different values

The clusters occurring

in the “sample” HCM at different values ![]() were of utmost interest. For each of

these clusters the maximum size or

the largest distance between the centers

of two particles in the cluster is

determined.

were of utmost interest. For each of

these clusters the maximum size or

the largest distance between the centers

of two particles in the cluster is

determined.

The simulation results show that with the increase of volume concentration of particles

increases the maximum size of the

largest cluster. With concentrations

of ![]() particles

in HCM

less than critical

particles

in HCM

less than critical ![]() (depending

on the size of the "sample"), the system

has only isolated clusters

with dimensions substantially smaller than the calculated "sample." With the increased concentration of

(depending

on the size of the "sample"), the system

has only isolated clusters

with dimensions substantially smaller than the calculated "sample." With the increased concentration of ![]() particles

the cluster

size and a probability of occurring of a cluster that pervades the entire "sample" (percolation

cluster) including a large mass of original particles [18] increase (on

average) as well. At concentrations of aluminium

particles

the cluster

size and a probability of occurring of a cluster that pervades the entire "sample" (percolation

cluster) including a large mass of original particles [18] increase (on

average) as well. At concentrations of aluminium ![]() in a system with a probability close to

unity, there occurs a percolation cluster, whose

weight varies significantly from a

calculation to a calculation. With the increase of dimensions of the

projected «sample»

in a system with a probability close to

unity, there occurs a percolation cluster, whose

weight varies significantly from a

calculation to a calculation. With the increase of dimensions of the

projected «sample» ![]() slightly increases. Extrapolation of the obtained data

to the infinite "sample" HCM shows that the percolation limit of the system of identical spherical particles is the

concentration

slightly increases. Extrapolation of the obtained data

to the infinite "sample" HCM shows that the percolation limit of the system of identical spherical particles is the

concentration ![]() These data agree well with the

results of [19, 20] which investigated

concentration limits of the combustion

wave spreading in heterogeneous

systems. Combustion in HCM considered

in [19, 20] took place due to the

heat transfer through the chain of

contact particles and also due to

a chemical reaction of contact particles,

and stopped when these chains

broke. Thus, the presence of a

percolation cluster was a necessary

condition for stable combustion in the considered HCM which

made it possible to establish

These data agree well with the

results of [19, 20] which investigated

concentration limits of the combustion

wave spreading in heterogeneous

systems. Combustion in HCM considered

in [19, 20] took place due to the

heat transfer through the chain of

contact particles and also due to

a chemical reaction of contact particles,

and stopped when these chains

broke. Thus, the presence of a

percolation cluster was a necessary

condition for stable combustion in the considered HCM which

made it possible to establish ![]() .

.

When approaching the percolation limit ![]() at

low concentrations

there are significant fluctuations in

the size of the largest cluster, and the smaller "sample" is, the larger these

fluctuations are. Existence of a threshold concentration (percolation

limit) leads to a phenomenon similar

to the phase transition of the second

order [21]: in passing through the percolation limit there is an abrupt change in the

properties of HCM which is defined

by contact particles, such

as thermal conductivity, electrical

conductivity, etc. In this case, the volume concentration of the particles

at

low concentrations

there are significant fluctuations in

the size of the largest cluster, and the smaller "sample" is, the larger these

fluctuations are. Existence of a threshold concentration (percolation

limit) leads to a phenomenon similar

to the phase transition of the second

order [21]: in passing through the percolation limit there is an abrupt change in the

properties of HCM which is defined

by contact particles, such

as thermal conductivity, electrical

conductivity, etc. In this case, the volume concentration of the particles![]() plays the

role of an order parameter. In metallized HCM

when

plays the

role of an order parameter. In metallized HCM

when ![]() due to sticking together of the particles in the percolation cluster during a combustion process there may appear a

frame made of metal particles that

will remain after combustion of the HCM

sample and the HCM will retain its

original shape.

due to sticking together of the particles in the percolation cluster during a combustion process there may appear a

frame made of metal particles that

will remain after combustion of the HCM

sample and the HCM will retain its

original shape.

Fig. 3. The number of

original particles in the clusters for different effective concentrations of

particles in HCM (line - the upper limit ![]()

Let's consider the results of the simulation

of a system with monodisperse particles

with respect to the distribution of

aluminum in metallic HCM. Fig. 3 shows numbers of original particles of aluminum in different clusters in different

effective concentrations ![]() Here we used data for the

following samples 20õ20õ20 and 30õ30õ30.

Here we used data for the

following samples 20õ20õ20 and 30õ30õ30.

It is evident that for every value ![]() maximum number of particles combined in one cluster does not exceed a certain value. The line

maximum number of particles combined in one cluster does not exceed a certain value. The line

![]() (2)

(2)

limits above all

calculated values and can

be regarded as a relation (in

a statistical sense) of the maximum

number of primary particles in

the cluster under the given effective

concentration of aluminum in HCM.

The estimation shows that the relation

(2) limits the weight of the maximum cluster with a probability close to one.

The formula (2) shows that the weight if the maximum cluster of

aluminum particles in HCM grows exponentially with concentration ![]()

There have been recent publications which establish the fractal nature of energy release during combustion of HCM [22]. Obviously, this is possible only

provided there are fractal structures in

the original HCM. Analysis of

the results of a mathematical modeling

in respect to monodisperse particles showed that any fractal structures (in the

strict sense of the word) are absent in the original HCM. But it

has been found that clusters of

contact particles of aluminum in an original HCM form fractal structures.

The analysis shows that the clusters

are by an average stretched in one direction, the calculated points

are grouped near the following power-law relation

(3)

(3)

which is characteristic for fractal structures where

![]() is a factor which may be considered

as the "fractal dimension" of

the cluster;

is a factor which may be considered

as the "fractal dimension" of

the cluster; ![]() is a

constant multiplier.

is a

constant multiplier. ![]() for identical spherical particles dispersed in a free space.

for identical spherical particles dispersed in a free space.

It should be noted that a similar relation was obtained for carbon black

aggregates appearing during

combustion of hydrocarbon fuels

[23], and the fractal dimension

of the aggregates was 1.74 units. This may indicate a single mechanism of structure formation

of aggregates (clusters) of

particles, regardless of their nature.

The published data show [23], that clusters of identical

contact particles make perforated

surface structures. This agrees with the results published in the paper

[24] which describes structures formed of aluminum particles which were found in a metallized

HCM.

Since clusters extend along an axis, then they can be regarded as linear and heat conductive elements connecting HCM burning surface with its deep layers, and therefore actively participating in the combustion process.

It must be noted that the relation (3) is valid both for particles of ammonium perchlorate (AP) and for aluminum particles in a metallic HCM, when distribution of aluminum particles is not dependent on size and distribution of AP particles (i.e. when AP particles and aluminum may be independently placed in the volume of the HCM).

A comparison of the relations (2) and (3) shows that the maximum size of the largest cluster of contact aluminum particles grows exponentially with the increase in the effective concentration

of aluminum in the HCM:

This relation allows us to estimate a range of applicability of the present method

of independent distribution of AP

particles and particles of finely divided aluminum in modeling the

structure of a HCM. Obviously,

such a method is reasonable only when the characteristic distance between AP particles is substantially larger than the maximum cluster of aluminum particles: ![]() where the characteristic

distance between AP particles

where the characteristic

distance between AP particles ![]() and the

proportionality factor is

and the

proportionality factor is

Òhus, independent positioning of AP and aluminum

particles in the volume of a HCM is possible in modeling its structure only when

(4)

(4)

From this relation, for example, it follows that if ![]() and

and ![]() cluster structures

will not depend from sizes of AP particles if

cluster structures

will not depend from sizes of AP particles if  and if

and if ![]() and the same

and the same

![]() if

if

If (4) is not satisfied, the average sizes and weights of clusters,

even for ultrafine original

particles of aluminum will

be dependent upon sizes of AP particles.

will

be dependent upon sizes of AP particles.

Fig. 4. Dependence of

the average coordination number of the cluster on the number of original

particles contained in it

Îne of the important characteristics

of a cluster is an average coordination

number (the average number of contacts per one particle in a cluster) which determines the strength of the cluster and, therefore, the

strength of the carcass layer on the combustion surface, and the tendency

of the cluster to form a single drop after

its melting. If (4) is not satisfied, the average sizes and weights of clusters, even for ultrafine

original particles of

aluminum  will be dependent upon sizes

of AP particles.

will be dependent upon sizes

of AP particles.

Average coordination numbers ![]() of clusters obtained as a result of modeling the structure of HCM in terms of

number of particles in the cluster

of clusters obtained as a result of modeling the structure of HCM in terms of

number of particles in the cluster ![]() are marked in Fig. 4. As it turned out, the relation

are marked in Fig. 4. As it turned out, the relation ![]() decomposes

into a

discrete number

of branches asymptotically approaching

decomposes

into a

discrete number

of branches asymptotically approaching ![]() which is

also a branch of the referred relation. The relation

which is

also a branch of the referred relation. The relation![]() is regular within each branch. Distribution of average coordination numbers of clusters in HCM becomes apparent in the

fact that they may belong to different branches of the relation

is regular within each branch. Distribution of average coordination numbers of clusters in HCM becomes apparent in the

fact that they may belong to different branches of the relation ![]()

An analysis has shown that the coordination number of the cluster ![]() is related to the number of particles in the cluster by a simple relation

is related to the number of particles in the cluster by a simple relation

![]() (5)

(5)

where ![]() is a

structural factor determining the type of a cluster. Each branch in the

relation

is a

structural factor determining the type of a cluster. Each branch in the

relation ![]() has a correspondent

value

has a correspondent

value ![]() and a cluster

type. These relations calculated for different

and a cluster

type. These relations calculated for different ![]() are

represented in Fig. 4.

are

represented in Fig. 4.

An analysis of clusters belonging to different branches of a relation shows that clusters of different types differ in the number of cyclic structures (loops). The structure factor is related to the number of loops ![]() in the

cluster by the relation

in the

cluster by the relation ![]()

CONCLUSIONS

1.

There has been proposed an analog model and a new

algorithm for random distribution of hard spheres in space (hard disks on the plane), which is

applicable to any distribution of particle diameters and volume concentrations up to the maximum

possible corresponding to close packing of the particles. The proposed method is called the method of viscous suspension.

2. There has been conducted a

simulation of the structure of heterogenous condensed mixtures containing one or two monodisperse particles in

a wide range of their volume concentrations.

We determined the main statistical

characteristics describing the internal

structure of HCM. It has been

shown that the method of viscous suspension allows simulating a appearance of regular structures when the volume concentration of the particles

is close to the maximum possible corresponding close packing.

3.

It has been demonstrated that the contact particles make in

HCM extensive clusters, whose dimensions increase with the increase of volume

concentration of the particles. If

the volume concentration of

particles in the system is greater than 0.15 ... 0.17,

the system with probability one will have a percolation cluster that would penetrate through the entire system,

and would be capable of changing its thermo-physical and

ballistic properties.

4. We demonstrated that clusters of aluminum contact particles in metal containing HCM have fractal structure,

which fractal dimensions change from

2.0 for small concentrations of aluminum particles in HCM to 1.8 for relatively high

concentrations.

5. We have studied the structure of clusters

of contact particles. It has been demonstrated that the average

coordination number of clusters containing

the same number of particles can

only take discrete values, which

are determined by the presence cyclic elements in

the structure.

References

1.

Strauss D.J. A model for clustering. Buiometrica, 1975, V.63,

p.467-475.

2.

Stoyan, D., Kendall, W.S., Mecke, J. Stohastic Geometry and its

Applications. Akademie-Verlag Berlin, 1987, 345 p.

3.

Ripley, B.D. Spatial Statistics. J. Wiley&Songs, New

York/Chichester. 1981. 252 p.

4.

Jodrey W.S., Tory E.M. Computer simulation of close random packing of

equal spheres. Physical Review A, 1985, V.32, ¹4, P.2347-2351.

5.

Jackson, T.L., Buckmaster, J. Heterogeneous

Propellant Combustion. AIIAA Journal, 2002, Vol. 40, pp. 1122-1130.

6.

Rashkovsky S.A. Simulation of composite explosives statistical

structure. In: Proceeding of Eleventh symposium on Chemical Problems, Connected

with the Stability of Explosives, Bastad, Sweden, 1998, P.17-18.

7.

Rashkovskii S.A. Structure of heterogeneous condensed mixtures. Combustion,

Explosion and Shock Waves, 1999, pp. 523-531.

8.

Nickolay Zosimovych, Banshidhar Choudhary. The Structures of

Heterogeneous Condensed Mixtures. PARIPEX

- Indian Journal of Research, Vol. 3, Issue: 4, pp. 135-141, May, 2013.

9.

Ji-Guang Li, Takayasu Ikegami, Jong-Heun Lee, Toshiyuki Mori, Yosiuki

Yajima. Co-precipitation synthesis and sintering of yttrium aluminum garnet

(YAG) powders: The effect of precipitant. Journal of the European Ceramic

Society, #20, pp. 2395-2405, 2000.

10. Sullivan K.T., Piekiel N.W., Wu C., Choudhury

S., Kelly S.T., Hufnagel T.C., Fezzaa K., Zachariah M.R. Reactive sintering: An

important component in the combustion of nanocomposite thermites. Combustion

and Flame, #159, pp. 2-15, 2012.

11. Croxton, Clive A. Liquid State Physics. A

Statistical Mechanical Introduction. Cambridge University Press, 421 pp., 1974.

12. Rashkovsky S.A. Simulation of composite explosives

statistical structure. In: Proceeding of Eleventh symposium on Chemical

Problems, Connected with the Stability of Explosives, Bastad, Sweden, 1998,

P.17-18.

13. Balescu Radu. Equilibrum and Nonequilibrum

Statistical Mechanics, Wiley, New York, 1975.

14. Allergini P., Grigolini P., West B.J.

“Preface”, Chaos, Solutions&Fractals, 2007.

15. Robert A. Beddini, Ted A. Roberts. Effects of

Turbulence on Stationary and Non-Stationary Process in C-Systems, University of

Illinois, Urbana, Fianal Technical Report ¹AAE 87-1 UILU ENG870501, 1989.

16. Garry A. Flando, Sean R. Fischbach, and

Joseph Majdani. Nonlinear rocket motor stability prediction: Limit amplitude,

triggering, and mean pressure shift. Physics of Fluids, 19, 094101, 2007.

17. Ãðèãîðüåâ Â.Ã., Êóöåíîãèé Ê.Ã., Çàðêî Â.Å. Ìîäåëü

àãëîìåðàöèè àëþìèíèÿ ïðè ãîðåíèè ñìåñåâûõ êîìïîçèöèé. ÔÃÂ, Ò. 17, ¹ 4, Ñ. 9-17,

1981.

18. Yupu Zang, Xu Xu, He Liu, Yujuan Zhai, Ye

Sun, Hangi Zhang, Aimin Yu and Yighna Wang. Matrix solid-Phase Dispersion

Extraction of Sulfonamides from Blood. Journal of Chromatographic Science, #50,

pp. 131-136, 2012.

19. Ôðîëîâ Þ.Â., Ïèâêèíà À.Í., Íèêîëüñêèé Á.Å. Âëèÿíèå

ïðîñòðàíñòâåííîé ñòðóêòóðû ðåàêöèîííîé ñðåäû íà òåïëîâûäåëåíèå ïðè îáðàçîâàíèè

àëþìèíèäîâ íèêåëÿ è öèðêîíèÿ. Ôèçèêà ãîðåíèÿ è âçðûâà, Ò. 28, ¹5, Ñ.95-100,

1988.

20.

Ôðîëîâ Þ.Â., Ïèâêèíà À.Í., Íèêîëüñêèé Á.Å. Êîíöåíòðàöèîííûå ïðåäåëû

ðàñïðîñòðàíåíèÿ âîëíû ãîðåíèÿ â ãåòåðîãåííûõ ñèñòåìàõ. Ãîðåíèå ãåòåðîãåííûõ è

ãàçîâûõ ñèñòåì, IX Âñåñîþçíûé ñèìïîçèóì ïî ãîðåíèþ

è âçðûâó. – ×åðíîãîëîâêà, Ñ.17-21, 1989.

21.

Adams Nicholas J. Dynamic Trees: A Hierarchial

Probabilistic Approach to Image Modelling. Edinburgh Research Archive, PhD

Dissertation, 2001.

22.

Ôðîëîâ Þ.Â., Ïèâêèíà À.Í. Ôðàêòàëüíàÿ

ñòðóêòóðà è îñîáåííîñòè ïðîöåññîâ ýíåðãîâûäåëåíèÿ (ãîðåíèÿ) â ãåòåðîãåííûõ

êîíäåíñèðîâàííûõ ñèñòåìàõ. Ôèçèêà ãîðåíèÿ è âçðûâà, Ò. 33, ¹5, Ñ.3-19,

1997.

23.

Koylu U.O., McEnally C.S.,

Rosner D.E., Pfefferle L.D. Simultaneous Measurements of Soot Volume Fraction

and Particle Size/Microstructure in Flames Using a Thermophoretic Sampling

Technique. Combustion and Flame, V.110, P. 494-507, 1997.

24.

Sambamurthi T.K., Price

E.W., Sigman R.K. Aluminium agglomeration in solid-propellant combustion //

AIAA Journal. V. 22, ¹8, p. 1132-1138, 1984.