Master Semernin N.A., C.t.s. Semernin

A.N.

M.Kh. Dulati Taraz state university, Kazakhstan

Perspective

methods of non-destructive testing in “Kazphosphate” LLP of Zhambyl region

The study of the

means and methods of nondestructive testing during operation, repair and forecasting

of residual resource of the rolling stock in plants and depots showed that by a

number of parameters of the controlled

units, assemblies and components of rolling stock there is no reliable methods

and means for complete control.

The most common method

is the magnetic particle inspection, the ultrasonic testing has the second place, eddy current method

goes further.

Paradoxical situation has come. Here is an example: one of

the causes of fractures of parts

of trucks in operation – the presence of casting defects,

including internal, which were not identified

at the factory. And to identify these

defects in the manufacture or

operation of parts of trucks is not necessary.

It is necessary to have a sufficient set of tools for the detection of internal defects and improve the detection of surface defects

of parts trucks so that to improve

traffic safety.

Now let us consider modern system of non-destructive

testing of rolling stock:

1. As is

well known the diagnostics is a

system of the type "control

+ prediction of residual life."

The first part of this system is not a big problem if

the applied method of control

has been well studied and validated

for the specific object of control; there is a small problem with the sensors. Because as

their work depends on the completeness and accuracy of the received information.

If not

using the system of parts

recovery or components and

assemblies of rolling stock, the non-destructive

testing works on the principle of

"serviceable - defective."

Restoration of products is used only when they have sufficient

untapped resource and it is brought to the working

condition in the production, as a rule, in scheduled maintenance.

The problem is

the second component of the diagnostic

system – the forecast of the residual resource.

2. At

present, there are many attempts

to create engineering forecasting

methods, the most famous of which

are: analytical, statistical and

probabilistic. It should be noted that the existing methods

of forecasting has not been developed yet and

have little practical value. This is due, above all, to the need to obtain vast information, its generalization and response to change. Therefore, all the works in the creation of residual life assessment

techniques are extremely useful and relevant.

Analysis of the state of the

freight wagons of LLP

"Kazphosphate" Zhambyl region shows that the average age of the main types of freight rolling stock

is more than 20 years at the appointed time service for 32 years (see figure 1). The order of the work to extend the life period

is regulated by "Regulations to

extend the service life of

freight cars plying in

international circulation" and "Uniform

guidelines on technical diagnosis of

the cargo and refrigerated wagons." The latter document

proposes as the main methods of non-destructive testing the magnetic particle

and ultrasonic inspection.

Figure 1.

The “Kazphosphate” LLP tank wagons with yellow phosphor inside

These methods of nondestructive testing

methods are active,

and are based on the active cooperation

of the signal of a flaw

detector to a metal of construction, and the

information about the state of stress

of the tested object is indirect. Also, the use of these methods of nondestructive testing involves time consuming.

Application of the methods

of passive control for technical diagnostics, based on the use

of faulty material as the source of the recording of the physical field, allows us to estimate

the actual stress-strain state

of the structure. Passive method of nondestructive testing is the method

of acoustic emission diagnostics.

Acoustic emission is the

control of the emission

of acoustic waves caused by a

sudden rearrangement of the

structure of the material. Register of waves and their transformation by using piezoelectric sensors allows to

judge about processes occurring

in the material [1,2].

The method is

widespread in diagnosing

of pipelines and vessels, working under

pressure.

The above method is

proposed to be used in the testing of tank of wagons of "Kazphosphate"

LLP in Zhambyl region. The need to load the

object of control by force or pressure

so that to generate in it sources the acoustic emission allows to combine acoustic

emission control with the hydraulic pressure test of the tank. Acoustic emission method allows you to control

the entire object using a fixed transducers system that reduces the time

and cost. The number of sensors

can vary within wide limits (from 2 to 80) (see figure 2) [2], which allows to carry out the high-quality

non-destructive testing of especially

responsible railway tanks.

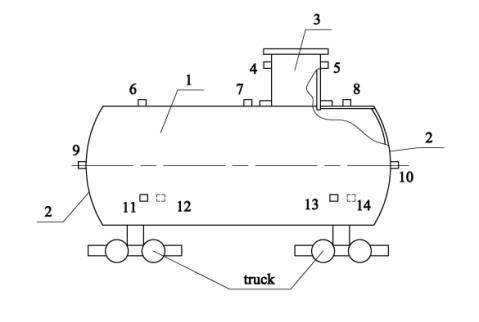

Figure 2. An

example of the scheme of arrangement

of the sensors during the acoustic

emission testing of tank

1 – tank; 2 – bottom;

3 – neck; 4-14

– transducers

The only limitation of

application of acoustic emission method for testing of tank wagons is the difficulty of separation of acoustic emission signals from the noise and signal interpretation, due to

the fact that the acoustic emission

signals are noise-like [1]. This disadvantage

is likely to be eliminated by developments of catalog

of reference defects that need to be compared with the actual picture of the

stress-strain state of tank wagons during the acoustic emission

testing.

The method of acoustic

emission diagnostics of rolling stock

is the most promising in terms of

the possibility of determining the

residual life of tank wagons of "Kazphosphate"

LLP on the basis of a viewing a clear

picture of the actual stress-strain

state of the controlled object.

On the basis of the analysis we may advise to carry out the following integrated activities:

1. Creation

on the basis of one of the contracting

companies of "Kazphosphate" LLP of the experimental and testing center

equipped with all existing types of testing and diagnostic

equipment for fully integrated

non-destructive testing and diagnosing

of new and in-service rail vehicles.

2. Carrying out of the search, research, verification and certification of new most

effective nondestructive inspection of railway tanks all over their volume.

3. Approval of the

list of primary and backup methods

(means) of nondestructive

testing for the detection of all

types of defects.

REFERENCES

1. Standard

20415-82. Non-destructive testing.

Acoustic methods. General provisions [Text]. – 1982. – 4 p.

2. RD

03-131-97. Rules of organization and carrying out of acoustic

emission testing of vessels, vehicles, boilers and process piping [Text]. – M .: NPO MBT – 2000. – 15 p.

3. Semernin, N.A.

Perspectives of technology of non-destructive testing in railway transport [Text] /

N.A. Semernin, A.N. Semernin, N.S. Nauryzbajev // Mechanics &

Technologies, Taraz: Taraz University, – 2014, ¹3, P. 89-92.