Tereshatov V.V., Makarova M.A.,

Senichev V.Yu.,Vnutskikh Zh.A., Savchuk A.V., Slobodinyuk A.I., Kiselkov D.M.

Federal

State Budget Foundation of Science Institute of Technical Chemistry of Ural

branch of Russian Academy of Sciences. Perm, Russia

Obtaining and

properties of tetrablock-polyurethane ureas with mixed polyether segments and

various hard ones

An overwhelming majority

of urethane-containing polymers (polyurethanes, polyurethane ureas) consist of soft

(SS) and hard (HS) segments (blocks) forming polymer chains [1,2]. The structure

of the soft segments is determined by used oligomers. Reaction of diisocyanate

and low-molecular-mass diol, or diamine results in formation of hard segments. Some

compositions contain cross-linking agents and plasticizers [3]. A difference in

polarity of soft and hard segments leads to their microphase separation and

formation of soft and of hard nano-dispersed phases. Hard domains are

stabilized by hydrogen bonds [2].

Properties of

urethane-containing materials are regulated varying the chemical structure,

molecular weight, polarity of soft segments, as well as concentration and

structure of hard segments. Thus, materials with diverse properties were

developed. Usually, segmented polyurethanes (SPUs) and polyurethane ureas

(SPUUs) consist of alternating uniform soft SS and hard HS segments (SSHS)n

[1]. Structure and properties of such materials are well-studied.

Urethane-containing multiblock-copolymers are much less investigated.

New investigation

objects are of significant interest for detecting particularities of behavior

for urethane-containing elastomers with a complex structure of the polymer

chains. This paper presents results of the synthesis and investigation of

thermal, thermo-mechanic, physic-mechanic and other properties of

tetrablock-copolymers containing various polyether soft segments and various

hard blocks (segments).

Segmented polyurethane

ureas (SPUU) with mixed polypropileneoxide (PPO) soft segments and polytetramethyleneoxide

(PTMO) ones of various molecular mass (Mn)

were investigated. The following compounds were used as initial components for

the synthesis of SPUU: 2,4-toluene diisocyanate (TDI) , isophorone diisocyanate

(IDI), oligopropylene oxide diol (PPO) Voranol 1010L with Mn=1000 g·mol-1, oligotetramethylene oxide

diol with Mn=1000 g·mol-1,

and 4,4¢-methylene-bis-(2-chloroaniline)

(MOCA). The synthesis was performed as a two-step process, with preliminary

preparation of prepolymers: TDI- and PPO-based FP-1 and IDI- and PTMO-based

FP-2. Prepolymers FP-1 and FP-2 were mixed in the given ratio. Then, the melted

MOCA was introduced into the reactor. Hardening of samples was provided within

3 days at 90oC.

Glass transition

temperature (![]() ) of the soft segments matrix (soft phase) of investigated

elastomers was determined with use of the DSC 822e calorimeter;

softening temperature

) of the soft segments matrix (soft phase) of investigated

elastomers was determined with use of the DSC 822e calorimeter;

softening temperature ![]() of the hard phase was

determined with use of the TMA/SDTA 841e device. Mechanical tests were

conducted at the stretching rates from 0.28 s-1.

Tensile strength

of the hard phase was

determined with use of the TMA/SDTA 841e device. Mechanical tests were

conducted at the stretching rates from 0.28 s-1.

Tensile strength ![]() (maximal stress value

calculated for initial cross-sectional area of samples), relative critical

strain value

(maximal stress value

calculated for initial cross-sectional area of samples), relative critical

strain value ![]() (%), engineer modulus E100

(stress value calculated for initial cross-sectional area of samples at 100%

relative strain), and true tensile strength

(%), engineer modulus E100

(stress value calculated for initial cross-sectional area of samples at 100%

relative strain), and true tensile strength![]() , where

, where ![]() were determined.

Rheological properties of reaction mixes (reaction masses) were investigated

with use of Reotest-2 equipped with the «cone-plate» device at 90±0.5°С, and at the share rate of 180 s-1.

were determined.

Rheological properties of reaction mixes (reaction masses) were investigated

with use of Reotest-2 equipped with the «cone-plate» device at 90±0.5°С, and at the share rate of 180 s-1.

Elastomers based on prepolymer FP-1 and

FP-2 blends, contain different quantity of polypropylene oxide SSPPO

and polytetramethylene oxide SSPTMO soft segments and hard segments

of various types:

HS1 (TDI- and МОСА-based)

HS2 (IDI- and МОСА-based)

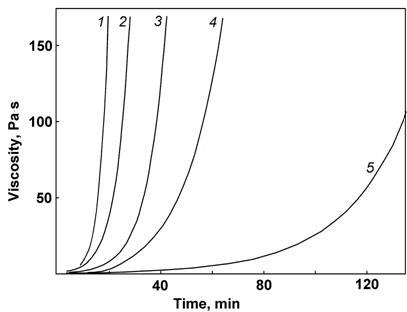

Results of rheokinetic study of

compositions on the base of prepolymers FP-1 and FP-2 showed an intensive increase in viscosity at 90°С to be observed within

the period less than 15 min for system FP-1 +МОСА, but after 100 min for

FP-2+МОСА system. Rheokinetic curves of

the compositions based on prеpolymer blends are

greatly shifted towards the curve corresponding to the composition based on

FP-1 (Fig. 1). Thus, interaction rates of the prepolymers with aromatic diamine

are different. The obtained data allow us to suppose that FP-1 in prepolymers blend

predominantly reacts with МОСА at the initial stage of

polyurethane ureas synthesis. This reaction leads to the formation of hard

segments HS1. Further FP-2 reacts with

diamine to form hard segments HS2 and PTMO soft segments. Taking

this into account the structure of multi-block copolymer chains can be

represented by the following simplified formula: (SSPPOHS1)m–(SSPTMOHS2)n.

The fragments of SPUU polymer chains consist of different types of hard and soft segments provided that oligodiisocyanate reactivity varies significantly. Molar ratio of PTMO and PPO soft segments is equal to the one of FP-2 and FP-1.

|

The molar fraction of the hard

segments HS2 in the composition of

urethane urea segments HS1+HS2 is close to the molar

fraction of prepolymer FP-2 in the blend with FP-1. Thus, the composition of

soft and hard segments in SPUU corresponds to the composition of FP-1 and

FP-2 prepolymer blend, used at the synthesis of the material. The evidence of sole glass transition temperature for soft phase in

SPUU indicates the thermodynamic compatibility between PTMO and PPO segments. |

|

|

Fig.1Rheokinetic curves at 90oC for compositions with various molar

fraction of FP-2 in the mix with FP-1: 1-0, 2-0.3, 3-0.5, 4-0.7, 5-1.0 |

Thermal and physic-mechanic

properties of polyurethane ureas depend on the molar composition of the FP-1-FP-2 prepolymer mix in the non-linear manner, and,

correspondingly, on the ratio between polymer chains (SSPPOHS1)m

and (SSPTMOHS2)n

, where n ≈ x2 (Table).

An optimal combination

of microphase separation and interchain interaction in the soft phase leads to

the significant improvement of strength and strain properties of the

multiblock-copolymer at the FP-2 molar fraction

x2 ≈ 0.5 in the mix with FP-1. This effect combining

with good rheology properties of the reaction mass expands possibilities of new

materials application for various technologies.

Table. Properties

of SPUUs at the various FP-2 molar

fraction x2 in the mix with FP-1

|

x2 |

Tgs, °C |

Th, °C |

sk, MPa |

ek, % |

Е100, МPа |

fr, MPa |

|

0 |

-5 |

190 |

38.4 |

410 |

16.1 |

196 |

|

0.3 |

-18 |

176 |

42.5 |

512 |

8.4 |

260 |

|

0.5 |

-46 |

173 |

57.6 |

620 |

6.8 |

415 |

|

0.7 |

-61 |

171 |

52.1 |

607 |

5.8 |

368 |

|

1.0 |

-70 |

167 |

48.2 |

552 |

5.6 |

314 |

Acknowledgments This work was financially supported by the Russian Fund for Basic

Research and Government of Permskiy kray (Project 16-43-590647r_a).

References

1.

Petrovic

Z.S., and Ferguson J. Polyurethane elastomers. Prog Polym Sci

1991;16(5):695–836.

2.

Paiksung

C.S., Smith T.W., Sung N.H. Properties of Polyether poly(urethaneureas) based

on 2,4-toluelene diisocyanate. 2. Infrared and mechanical studies. Macromolecules 1980; 13(1):117–21.

3.

Volkova E.R., Tereshatov V.V., Vnutskikh Zh.A. Formation of polyurethane structural materials based

on blends of oligoethers with different reactivities. Russian J Appl Chem 2010; 83(8):1372–79.