Khusainov F.F., Khakimyanov M.I.

Ufa State Petroleum Technological University

Designing

of wireless sensors

Technological

processes in fuel and energy complex of industry, such as production,

transportation and refining of oil and gas, require deep introduction of

automatic control systems. These modern control systems are multi-level

complexes that provide maximum performance and reliability of process plants

during the entire cycle.

The

equipment of automatic control systems include sensors, different controllers,

control stations and channels of data transmission, which can be, wired,

optical, radio modem, cellular and satellite.

More

recently, at designing such systems, there has been a trend towards the use of

wireless technology as the use of sensors with wire interface often causes

certain difficulties associated with mounting the sensors on moving and

rotating objects, where the cable quickly wears out and breaks, as well as the

installation of a remote and distant places. Also it should be noted that the

organization of wireless communication channels, in most cases is much cheaper

than laying the special cable networks [1, 2].

However,

the use of wireless sensors associated with some operational disadvantages,

such as the need for regular replacement of batteries, the range of radio

transmission and of limited use because of the climatic conditions.

Decision

of the above disadvantages could be the use new types of chemical batteries

(lithium, silver-zinc and others) that have a high capacity (up to 10 A • h or

higher), and keep working in a wide range of temperatures (at temperatures down

to -30 ... 40 º C and below), as well as the emergence of new low-power

electronic parts and radio interfaces for the design of sensors for long life

operation without battery replacement [3].

One

of the most promising ways to solve the problems described above is the use of

alternative sources of energy: solar, heat, voltage generated by piezoelectric

generator in the sensors of weight and strength.

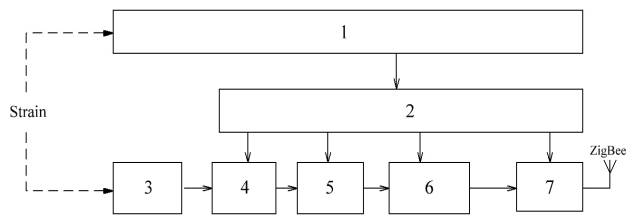

Figure

1 shows a block diagram of a load cell with a wireless interface, which is

powered by the electricity generated by the piezoelectric generator. The device

is used for the registration dynacards of sucker rod pumps, driven by a pumping

unit.

The

load cell is installed in the node rope suspension of pumping unit and measures

the effort generated between traverses with the reciprocating motion of the

rod. The load cell comprises a sensing elements SE, measuring circuit IC,

analog-to-digital converter ADC, a microcontroller and a radio transmitter IC

RP. Power to all elements of the sensor from a battery that is recharged with

electricity generated by the piezoelectric generator GHG its continuous cyclic

loading.

1 – piezoelectric

generator; 2 – battery; 3 – sensing elements; 4 – measuring circuit; 5 – analog-to-digital converter; 6 – microcontroller;

7 – radio transmitter

Figure 1 – Block diagram

of a wireless load cell with piezoelectric generator

All

electronic components of the sensor should have low power consumption, and in

between measurements switch into a "sleep mode." Modern

microcontrollers have quite energy efficient. In the "sleep mode" is

provided to the consumption of 100 nA, the internal clock consumes 800 nA.

Details of some of these MCUs are presented in Table 1 [4].

Table 1 -

Comparison of microcontrollers

|

|

MSP430F21X1 |

PIC16LF72X |

PIC18F14K50 |

PIC24F16KA102 |

|

Pin Count |

20/24 |

28/44 |

20 |

20/28 |

|

Flash-memory of programs |

4-8 |

3.5-14 |

8-16 |

8-16 |

|

EEPROM Data Memory |

- |

- |

256 |

512 |

|

RAM, byte |

256 |

368 |

768 |

1536 |

|

Consumption in

the "sleep", nA |

100 |

20 |

24 |

25 |

|

Time out from

the "sleep", mks |

3 |

5 |

5 |

1 |

|

Consumption of WDT, nA |

700 |

500 |

450 |

420 |

|

Consumption of RTC, nA |

700 |

500 |

790 |

520 |

|

Consumption when operating at a frequency of 1 MHz, uA |

250 |

110 |

170 |

195 |

It

should be noted that while reducing the level energy consumption of sensor

developers limited speed and metrological characteristics of the device. Since

the use of various software algorithms of digital signal processing, filtering

and integration can significantly increase the current consumption of the

microcontroller.

Thus,

there may be made the following conclusions:

1

The advantage of wireless sensors is the ability to install in remote and

distant places, moving and rotating objects, where the use of devices with a

wired interface is difficult.

2 Modern

microelectronic element base allows the design of low-power devices that can

provide continuous operation with battery.

3 When

using alternative renewable sources of energy can significantly increase the

continuous operation of wireless sensors.

References:

1. NI Wireless Sensor Networks: [site]. URL: http://sine.ni.com/np/app/main/p/ap/imc/lang/ru/pg/1/sn/n17:imc,n21:11297/.

2. Introduction to Wireless Sensors: [site]. URL: http://www.omega.com/prodinfo/wirelesssensors.html.

3. M.I. Khakimyanov. Wireless

technologies in industrial sensors // Improving the reliability and energy

efficiency of electrical systems and complexes: Interuniversity collection of

scientific papers / Editorial Board.: V.A. Shabanov. Ufa: USPTU, 2010. 189-198 p.

4. Compare 8-bit PIC® MCU Architectures: [site]. URL: http://www.microchip.com/pagehandler/en-us/family/8bit/architecture/home.html.