SOME

POINTS of the WAREHOUSE THEORY

Oleg B. Malikov, Ph.Dr., professor, St.Petersburg State Transport University

Abstract

Warehouses are main components of logistic chains. Supply chain may be

represented as consisted of warehouses, connected with transport links. Modern

mechanized and automatic warehouses are very complicated technical objects,

which feature with many parameters, a lot of technical decisions and operate under

stochastic influence of flows of arriving and dispatching cargoes. So they run

in permanent changing conditions of different cargo volumes, number of handling

equipment and employees used. Special theory is needed for the due research and

project these complex technical objects.

Keywords: Warehouse, Transport,

System, Material flow, Logistics,

Supply

Chain

Introduction

Warehouses and cargo terminals are wide spread

objects in all industries, trade and transport. Modern mechanized and automatic

warehouses are very complicated technical objects. They rigged with specific

complex equipment (racking systems of various performance up to 20 meters high,

industrial trucks and stacker cranes with automatic control, automatic conveyor

systems and automatic guided vehicles - AGV, means of robotics, palletizers,

computers and on-line electronic data exchange systems etc. They are

characterized with hundreds of various parameters and display stochastic sort

of activity under fluctuating action of material flows. In every case of reconstruction

or building some new warehouse a lot of options, with different parameters and

economical characteristics have to be calculated.

It

is impossible for engineers to consider all dozens of options of possible project solutions. Many profound researches should be carried

out to find the best solutions in many aspects.

Taking all these into account it is necessary to develop some special

theory of warehouses and cargo terminals research and projecting.

Warehouse

Theory

Hundreds

of warehouse projects were worked out by the author for about 20 industries

that made to understand the necessity of new special theory for warehouses and cargo terminals [1-3]. The

General Cybernetic Theory of Systems (GCTS) was applied as a foundation for this theory that was called of Warehouses

System Theory (WST). According to this

theory warehouse should be analyzed as a system, i.e. as a complex of connected

components, having been created for reaching unified objective. For creating

efficient warehouse thorough research should be fulfilled with the following

steps: objective of the system, its components, its structure, activity,

interaction with environment and results of operation. Simulation may be used

at all these steps.

Objective

of the warehouse system

This

is the basic aspect of the warehouse creation and functioning.

Common, or at any rate very wide spread opinion

is that warehouses are created for storage of merchandise. No products however are manufactured just for storage.

They should move to customer to be

consumed.

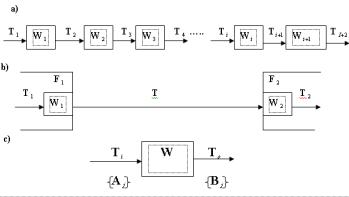

Supply Chain consists of 2 kind of elements:

warehouses and transport links, connecting these warehouses (Figure 1a). Any

well organized transportation process starts and terminates at some warehouses

(W![]() , W

, W![]() in Figure 1b). A warehouse always interacts with two type of

transport first Ti, that delivers cargoes to the warehouse and

second To, that delivers cargoes from warehouse to customers (Figure

1c).

in Figure 1b). A warehouse always interacts with two type of

transport first Ti, that delivers cargoes to the warehouse and

second To, that delivers cargoes from warehouse to customers (Figure

1c).

Figure 1. Logistic chain with main components - warehouses W![]() , W

, W![]() at facilities F

at facilities F![]() and F

and F![]() and connecting them transport links Ti

and connecting them transport links Ti

Each

of this material flows is characterized not only with whole capacity, but also with the following

parameters: volumes of transport batches; number of different items of cargoes

in transport batches; type and features of transport tare and packing of

cargoes; type and features of freight transport units; time of arrival and

dispatching of transport batches, regularity and conformity of these processes

to some rules; time intervals between

arrival and dispatch of transport batches and their regularity.

Comparison of these characteristics of in-bound and out-bound goods

flows displays, that they may be different from each other. So multitude A![]() of in-bound flow parameters can be not equal to the

appropriate elements of multitude B

of in-bound flow parameters can be not equal to the

appropriate elements of multitude B![]() of out-bound flow parameters (Figure 1,c). Warehouse transforms some of the flow

parameters, mentioned before [4].

of out-bound flow parameters (Figure 1,c). Warehouse transforms some of the flow

parameters, mentioned before [4].

For example, Logistic Center can change: volume

of the transport batches from big to the small ones, change pallets, transport

tare and packing of goods, number of

items in batches, time characteristics of transport batches dispatched etc.

So warehouses of various types and designations are created in the

points of interaction of different transport and industrial systems with an

objective of material flow transformation for the best consequent

transportation and/or using goods. Besides

the warehouse can be efficient if it for due flow transformation would spend as little as possible 6 main resources,

which we have in our real natural environment: space, time, materials, energy,

labor, money. WST provides special means and methods for this.

Components of the warehouse system

According

to WST the most productive approach for warehouse research was proved to select

as the system components: areas of cargo loading, unloading, reception,

storage, picking, inner warehouse

transport etc.

Everyone of these components

of a warehouse system has its own technology, equipment and purpose of functioning.

But there is one general system objective, which all the components operate

for. This is the united objective of creation of the warehouse to transform

the determined material flow in a specific way with the least spending of

mentioned above 6 resources. That is known as synergetic effect in the General

Theory of Systems.

Structure of the warehouse system

Structure

of the warehouse system represents the various interactions between elements of

the system: in space, time. warehouse technology, depending, economical

interaction, in organization, management and so on. It is these interactions of

the warehouse system components between one to another, that lend to the system

entirety, regularity and organization. Structure of the warehouse system should

be selected or created in such a way that it would allow in the most degree to

reach warehouse system its objective.

Functioning

of the warehouse system

In

every moment the warehouse system is in some state, that feature specific

parameters. These parameters may be

such as level of inventory, amount of machines

at work, occupation of areas with cargo, number of trucks at loading-unloading

docks, number employees at work and so on. During its operation the warehouse system interacts with environment, which consists of

a number of outside systems, and fluctuates from one state to another one. This

functioning of warehouse system should be projected so as it helped the

warehouse system to reach its main objective of material flow transformation.

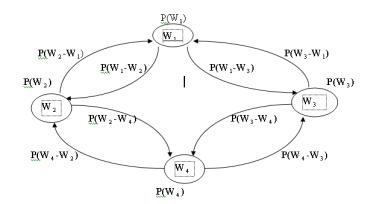

The number of these states may be very

large, and they are characterized with types and amount of technological

operations to be carried out at the moment. Main four warehouse states may be: only

cargo reception; only cargo dispatching; simultaneously cargo reception and

dispatching; no work at warehouse at all.

Ability of the warehouse system to be in some

state W![]() can be valued with its appropriate probability P(W

can be valued with its appropriate probability P(W![]() ) see Figure 2.

) see Figure 2.

Figure 2. Graph of states and transitions of a warehouse system (4 states

and

8 transitions illustratively) and their appropriate probabilities

Functioning of warehouse system can be represented in formulized view as

a matrix of transition probabilities:

![]()

![]() P

P![]() P

P![]() P

P![]() P

P![]()

P![]() P

P![]() P

P![]() P

P![]()

P![]() =

=

P![]() P

P![]() P

P![]() P

P![]()

P![]() P

P![]() P

P![]() P

P![]()

Probabilities disposed in the main diagonal of the matrix can be used

for calculation of possibilities of remaining of the warehouse system in the

same states.

This method of formalization of warehouse system functioning can be used

for its research and optimization, for example, for computation quantity of handling

equipment:

![]() ,

,

where

r - number of handling equipment;

n - number of warehouse possible states;

P(Wi ) the probability of the i-th state of the warehouse system.

Interaction

of the warehouse with environment

While operating the warehouse system interacts with environment, which

consists of a number of outside systems. This interaction with surrounding systems

should be planned so as it allowed the warehouse system to reach its main objective

of material flow transformation.

Practically this interaction the warehouse system with the environmental

systems represents mutual transferring material and informational flows, which

makes the warehouse to pass under this influence from one its state to

another.

Results

of the warehouse operation

Results of the warehouse system operation should be analyzed and compared

with the objective having been set at the beginning of its projecting. If the

results do not coincide with the objective, it is necessary to change some decisions.

Conclusion

Warehouse should be considered as a system with

specific objective, components, structure, functioning, interaction with environment

systems. This general methodology can

be used also for analyzing other objects in different fields (railway

stations, marine ports, parkings, garages, sport and cultural objects, shops

and markets etc.). These objects do

not produce some new products, but only transform flow parameters and are

very useful for the human society.

References

1.

O.Malikov,

Warehouses & Cargo Terminals. St. Petersburg, 2005, p. 650

2.

O.Malikov,

Business Logistics, St. Petersburg, 2003, p. 240.

3.

O.Malikov.

Warehouses of Flexible Manufacturing Systems. St.Petersburg, Russia, 1986,

p. 186

4.

O.Malikov. Projecting of Automatic Warehouses . St.Petersburg, 1980, p.240

Contacts:

190031, Russia, Saint Petersburg, Moskovskey ave., Petersburg State

Transport University. Department Logistics&Commerce. Ph.Dr, professor Oleg

B. Malikov

E-mail: stadnitskey@mail.ru mob. tel. 8-921-308-8098