B.Sazambayeva, G. Kuanyshev, M.Zhumanov, S. Kozhataev

Kasakh National Research Technical University Behalf

K.Satpayev,Almaty,22 Satpayev street

DETERMINATION

OF TORQUES ON THE TUBULAR BELT CONVEYOR

1.

Method calculating

of tubular belt conveyor

In operation, when

the design parameters of a tubular belt conveyor reach a certain value

(critical value), begins intensive growth of oscillation amplitudes. In this

case, the operation of the conveyor is not possible due to intense vibration.

Vibration breakages in the loss of stability is usually accompanied by costly

repairs, significant unplanned downtime and sometimes devastating consequences.

Used in work approach makes it relatively easy to analyze the vibration

resistance of pipelines and assess their critical parameters. Knowledge

of these parameters allows you to design quickly and produce

tubular belt conveyors with low vibration and high

operational reliability.

2. Perturbed motion of a

tubular belt conveyor Introduction

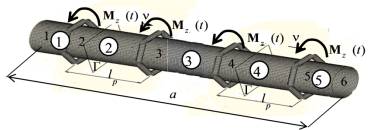

Consider the straight portion of the tubular

belt conveyor (Figure 1)

[1,2,3,4,5]

Fig. 1.

Finite element model of the linear

portion of the tubular conveyor

belt.

Consider the straight

portion of the tubular belt

conveyor as a set of five finite elements with

six nodes (Figure 1). Formation of the global matrix of inertia, stiffness, damping and vector nodal loads described

in [1,2]. Let us write the equation

of forced torsional oscillations of a straight section of the conveyor belt tube (Figure 1)

in the form of [6,7,8,9,10]:

(1)

(1)

with the initial conditions

![]() (2)

(2)

Here ![]() ,

,![]() ,

,![]() respectively global

matrix of inertia, damping and stiffness,

respectively global

matrix of inertia, damping and stiffness, ![]() global vector of external

forces. The matrices of inertia, stiffness and the nodal displacements vector of finite element model of the tubular belt conveyor have the

form [1,2]:

global vector of external

forces. The matrices of inertia, stiffness and the nodal displacements vector of finite element model of the tubular belt conveyor have the

form [1,2]:

In practical

calculations damping matrix for each ![]() finite element is represented as a linear

combination

finite element is represented as a linear

combination

![]() (3)

(3)

Where ![]() – proportionality

coefficients. For example,

when

– proportionality

coefficients. For example,

when ![]() damping matrix is

proportional to the matrix of

inertia ("external" friction),

when

damping matrix is

proportional to the matrix of

inertia ("external" friction),

when ![]() damping matrix is

proportional to the stiffness matrix ("internal" friction).

damping matrix is

proportional to the stiffness matrix ("internal" friction).

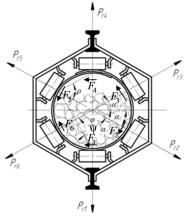

To determine the equivalent

nodal torsional moments ![]() , arising

from the interaction of the tape of the tubular conveyor with support idlers, consider

the tape movement inside the idlers.

Idlers are the

six rollers [8,14,15],,

, arising

from the interaction of the tape of the tubular conveyor with support idlers, consider

the tape movement inside the idlers.

Idlers are the

six rollers [8,14,15],,

forming a ring. Thus, the three upper and three

lower rollers rotating in opposite directions Fig.2.

Fig. 2.

The forces acting on the tape in idler

Due

[5,7,8,11,13]

![]()

Where ![]() pressure force on the i-th roller,

pressure force on the i-th roller, ![]() torsional shear angle. The rotating moment at the point of contact

of tape and i-th roller is calculated as:

torsional shear angle. The rotating moment at the point of contact

of tape and i-th roller is calculated as:

![]() (4)

(4)

Thus, the total torque with

(4) is equal to

![]()

Then the vector of

nodal loads to the m-th finite element, taking into

account (4) has view [2,3]

(5)

(5)

Consequently, the vector of

equivalent nodal loads ![]() of

concentrated torques in idlers will be equal to:

of

concentrated torques in idlers will be equal to:

Thus, the equation of

perturbed motion of torsional oscillations of the straight section of the belt tube conveyor

(Figure 1) has the form

(6)

(6)

It is

assumed that the damping matrix is

proportional to the matrix of

inertia. Thus, the coefficient of

proportionality ![]() .

.

Since oscillation

stability is determined by reacting the

first lower waveforms

in equation (6) as

a first approximation may be

considered not all waveforms

![]() but only

but only ![]() .

.

In this case, the

solution of equation (6) in the form

![]() ,

(7)

,

(7)

Where ![]()

![]() . Здесь

. Здесь ![]() – diagonal

matrix of squares of the natural

frequencies,

– diagonal

matrix of squares of the natural

frequencies, ![]() – identity

matrix of dimension (

– identity

matrix of dimension (![]() ),

),![]() –matrix

of natural modes of dimension (

–matrix

of natural modes of dimension (![]() ).

).

Inserting (7) into (6) and

cancel out the common multiplier ![]() we obtain the equation

we obtain the equation

![]() (8)

(8)

The characteristic equation for

determining the indicator ![]() takes the form

takes the form

![]() (9)

(9)

Here

![]() the matrix with dimension (

the matrix with dimension (![]() ).

).

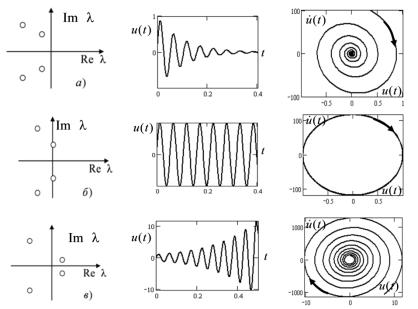

When you change

parameter ![]() the characteristic

indices

the characteristic

indices ![]() move in the complex plane (Fig.

3). The real roots of the equation (9) corresponds to a monotonous (not oscillating)

movements of the straight section

of the belt tubular conveyor and complex - the

oscillatory motion. Thus particular

solution will be attenuated,

periodical or infinitely increasing

function of time depending on whether

the real part of the root (9) is

negative (Fig. 3a), is zero (Fig. 3b)

or positive (Fig. 3c).

move in the complex plane (Fig.

3). The real roots of the equation (9) corresponds to a monotonous (not oscillating)

movements of the straight section

of the belt tubular conveyor and complex - the

oscillatory motion. Thus particular

solution will be attenuated,

periodical or infinitely increasing

function of time depending on whether

the real part of the root (9) is

negative (Fig. 3a), is zero (Fig. 3b)

or positive (Fig. 3c).

Figure

3.

Location roots of the equation (4) in the complex plane,

typical trajectories and

phase portraits.

In the field of

sustainability ![]() On the

part of the critical surface, which corresponds to the transition to the divergence, one of the characteristic roots of the equation (9) vanishes. On the critical surface, which corresponds to a transition to flutter at least a pair

of roots is a complex conjugate

(Fig. 3).

On the

part of the critical surface, which corresponds to the transition to the divergence, one of the characteristic roots of the equation (9) vanishes. On the critical surface, which corresponds to a transition to flutter at least a pair

of roots is a complex conjugate

(Fig. 3).

2. The solution of test task

To illustrate the practice

of the developed approach, consider the straight

portion of the tubular belt

conveyor (Figure 1) for the following parameters: ![]() the length of the linear portion of the conveyor;

the length of the linear portion of the conveyor; ![]() Нм - the resulting torque in idlers;

Нм - the resulting torque in idlers; ![]() м - the distance between the idlers;

м - the distance between the idlers; ![]() м - the mean radius of the circumference of the pipe;

м - the mean radius of the circumference of the pipe; ![]() м - tape thickness;

м - tape thickness; ![]() Pa - shear modulus;

Pa - shear modulus; ![]() angle

characterizing the degree of filling the cross section of the tape by load;

angle

characterizing the degree of filling the cross section of the tape by load;

![]() the density of coal;

the density of coal; ![]() the density of

tape;

the density of

tape; ![]() reduced density;

reduced density; ![]() the moment of inertia of rotation of the tube;

the moment of inertia of rotation of the tube; ![]() moment of inertia of the load rotation;

moment of inertia of the load rotation; ![]() linear mass moment of inertia;

linear mass moment of inertia; ![]() torsional stiffness section;

torsional stiffness section; ![]() m/s - the conveyor belt

speed.

m/s - the conveyor belt

speed.

Figure 4 shows

the dependence of the first two lower

frequency torsional vibrations,

and the real part of the characteristic

exponent ![]() of the tubular conveyor belt (Figure 1) as a function of the speed of the belt

of the tubular conveyor belt (Figure 1) as a function of the speed of the belt ![]() on the conveyor. The solid

and dashed lines correspond to the

first and second natural frequency of the torsional oscillations, respectively. From

Figure 4 it is seen that with increasing the speed of the conveyor belt lower natural frequencies decrease and when

on the conveyor. The solid

and dashed lines correspond to the

first and second natural frequency of the torsional oscillations, respectively. From

Figure 4 it is seen that with increasing the speed of the conveyor belt lower natural frequencies decrease and when ![]()

![]()

![]() , which corresponds

to the transition to unstable torsional vibrations according to the type of

divergence.

, which corresponds

to the transition to unstable torsional vibrations according to the type of

divergence.

Thus, the critical speed

of the conveyor belt as is equal

When ![]() torsional oscillations of the straight section of the

belt tubular conveyor are sustainable.

torsional oscillations of the straight section of the

belt tubular conveyor are sustainable.

3.

The main results and conclusions

The proposed approach is based

on the finite element method, makes

it relatively easy to assess

critical parameters of tubular belt conveyors. It is

shown that the critical speed of movement of conveyor belt is equal

References:

1.Дмитриев

В.Г., Сергеева Н.В. Определение распределенных сопротивлений движению ленты на

прямолинейных участках трассы ленточного трубчатого конвейера // Горный

информационно-аналитический бюллетень. - 2008. - №9. - С. 245 - 249.

2. Sarguzhin M.Kh., Dzhienkulov Z.S.,

Sazambaeva B.T., Imangaliyeva A.E.

Determination of

resistance to movement of the running belt circuit of conveyor syste// Materiály X mezinárodní

vědecko-praktická conference. «Efektivní nástroje

moderních věd – 2014»,

Díl 32. Technické vědy

3. Пертен Ю.А. Крутонаклонные конвейеры. Л:Машиностроение, 1977.-с.215.

4.

Дмитриев В.Г., Ефимов

М.С. Влияние различных факторов на угловые отклонения ленты трубчатого

конвейера. // Горный информационно-аналитический бюллетень. – М.: МГГУ, 2008. -

№8, с. 235 - 237.

5.

B. Sazambaeva , G. Kuanyshev,

Khadeev ,N.T.Zhumanov“On the question of the study of tubular belt conveyors for the

transportation of goods environmentally //Materias of XI International Research

and Praktike Conference SCINCE WITHOUT BORDERS-2015, March-April 7, 2015 / Science

and Education Ltd Sheffied S.60-66

6.

V.Radian, J.Samarin, V. Chirkov “Finite Element Method for dynamic

problems of strength of materials.” - M.: FIZMATLIT, 2013. - 316 p.

7.

Дьяченко А.В. Обоснование метода расчета напряженного состояния

сыпучего груза и нагрузок на опорные элементы при формировании желоба

трубчатого ленточного конвейера. дис. на соискание уч. ст. канд. техн. наук.

Московский государственный горный университет. М. 2006

8.

Сазамбаева Б.Т., Кәдірақын. Г Исследование параметров трубчатого ленточного конвейера

// Вестник КазНТУ №5.- Алматы,

2015С.104-106

9.

Модернизация

Красноярского цементного завода – сайт: www. http://www.sibcem.ru/

10. В.Н.Ивченко,

С.В.Куров, Беспросыпные ленточные конвейеры. Журнал "Горная Промышленность" №4 2005.

11.

В.Г. Дмитриев, Н.В. Сергеева Методика тягового расчета ленточного трубчатого конвейера Журнал "Горная

Промышленность" №4 2011

12.

Шахмейстер Л.Г., Дмитриев В.Г. Теория и расчет ленточных конвейеров. М.:

Машиностроение, 1987. - 336 с.

13.

Сергеева Н.В. Обоснование метода расчета распределенных сил сопротивления

движению ленты на линейной части трубчатого конвейера для горных предприятий. Автореф. дисс. на соиск. уч. степени канд.

техн. наук., Москва, МГГУ, 2000 -24 с.

14.

П.А. Бажанов Методы оптимизации параметров

трубчатого ленточного конвейера Горный информационно-аналитический

бюллетень, 2009, №9,

15.Куанышев

Г.И. Патент KZ № 29011 Трубчатый ленточный конвейер. Республика Казахстан,

Астана, 2014г.